Preparation method for magnetic graphene nanobelt/graphene composite film

A graphene nanoribbon and magnetic graphene technology, applied in the field of carbon nanomaterials, can solve problems such as cracks and reduced mechanical strength of materials, and achieve the effects of low cost, less process and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

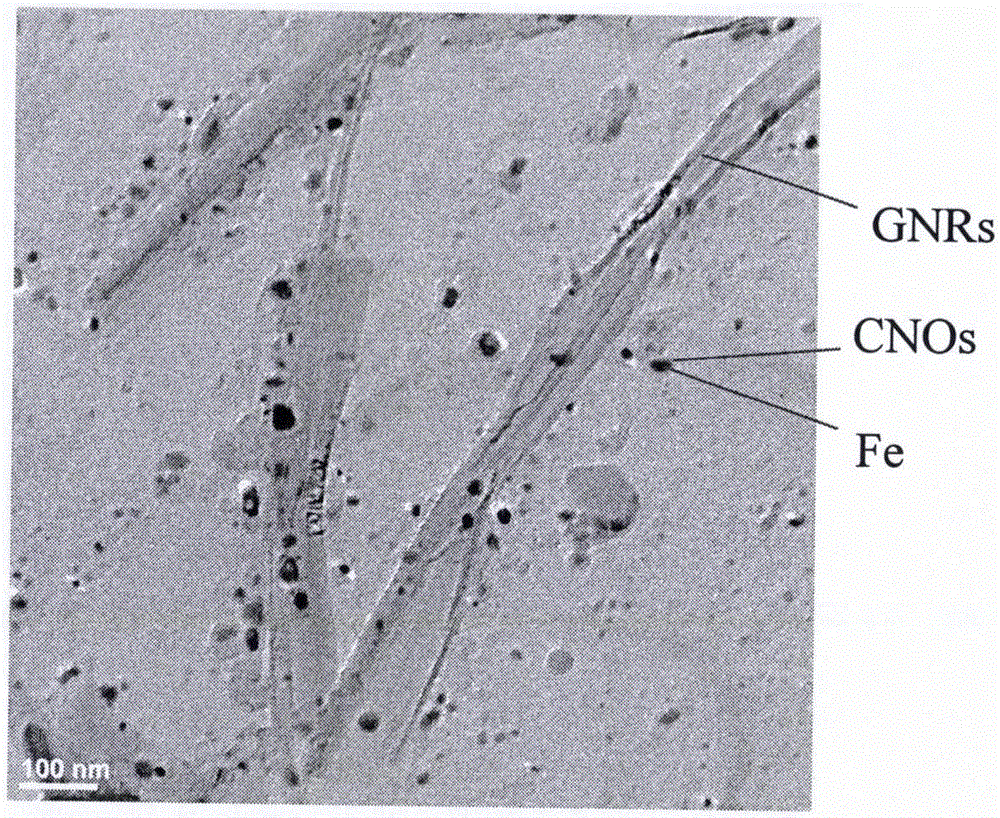

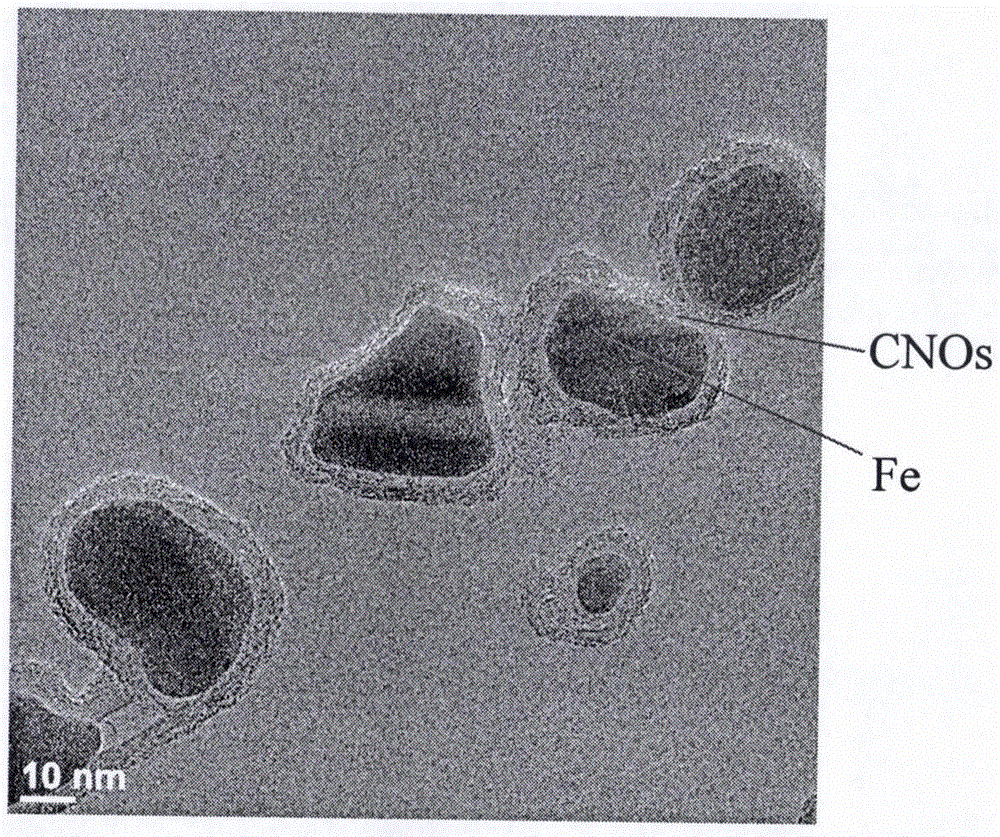

Image

Examples

Embodiment 1

[0032] The concrete steps of the preparation method of a kind of magnetic graphene nanobelt / graphene composite film are as follows:

[0033] 1) Loaded graphene nanoribbons

[0034]Put 9.2mg of F127 into 10ml of deionized water, stir well to obtain solution A with the concentration of F127 substance being 0.009mol / L; add 8.4mg of GNRs to solution A, and obtain GNRs substance after ultrasonic dispersion in an ice bath The concentration of the mixed solution B is 0.07mol / L, and the graphene nanoribbon in the mixed solution B is evenly loaded on the copper foil C, and the loading amount of the graphene nanoribbon on the metal foil C is 6 mg / cm 2 . Among them, the ultrasonic power is 85W, and the ultrasonic time is 20min.

[0035] 2) Graphene Nanoribbon Toughened Graphene Prepared by Chemical Vapor Deposition (CVD)

[0036] Turn on Ar, place the copper foil C described in step 1) in the constant temperature zone of the CVD furnace, and then turn off Ar. Vacuum down to -0.1MPa, ...

Embodiment 2

[0044] A kind of preparation method of magnetic graphene nanobelt / graphene composite film, with embodiment 1, wherein: in the 1st) step, 41.8mg SDBS is put into 60ml deionized water, after stirring, obtain the amount concentration of SDBS substance as 0.002mol / L solution A; add 61.2mg GNRs into solution A, and disperse evenly in an ice bath with 60W ultrasound for 30min to obtain a mixed solution B with a GNRs substance concentration of 0.085mol / L, and mix the mixed solution B evenly Spin-coated on copper foil C, the loading of graphene nanoribbons on copper foil C was 9.2 mg / cm 2 .

[0045] In step 2), Ar is turned on, the copper foil C described in step 1) is placed in the central chamber of the CVD furnace, and then Ar is turned off. Open H after vacuuming 2 , at 450sccm H 2 Heat reduction at 1100°C for 10min, then in 450sccm H 2 and 8 sccm CH 4 Chemical vapor phase growth in a mixed gas atmosphere for 15 minutes. Finally, the copper foil was quickly removed from the c...

Embodiment 3

[0049] A kind of preparation method of magnetic graphene nanoribbon / graphene composite film, with embodiment 1, wherein: in the 1st) step, 23.1mg SDS is put into 10ml deionized water, after stirring, obtain the amount concentration of SDS substance as 0.008mol / L solution A; add 6.24mg GNRs into solution A, and disperse evenly in an ice bath with 30W ultrasound for 60min to obtain a mixed solution B with a GNRs substance concentration of 0.052mol / L, and mix the mixed solution B evenly Sprayed on copper foil C, the loading capacity of graphene nanoribbons on copper foil C is 6mg / cm 2 .

[0050] In step 2), Ar is turned on, the copper foil C described in step 1) is placed in the central chamber of the CVD furnace, and then Ar is turned off. Open H after vacuuming 2 , at 300sccm H 2 Heat reduction at 900°C for 30min, then in 300sccm H 2 and 15 sccm CH 4 Chemical vapor phase growth in a mixed gas atmosphere for 50 minutes. Finally, the copper foil was quickly removed from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com