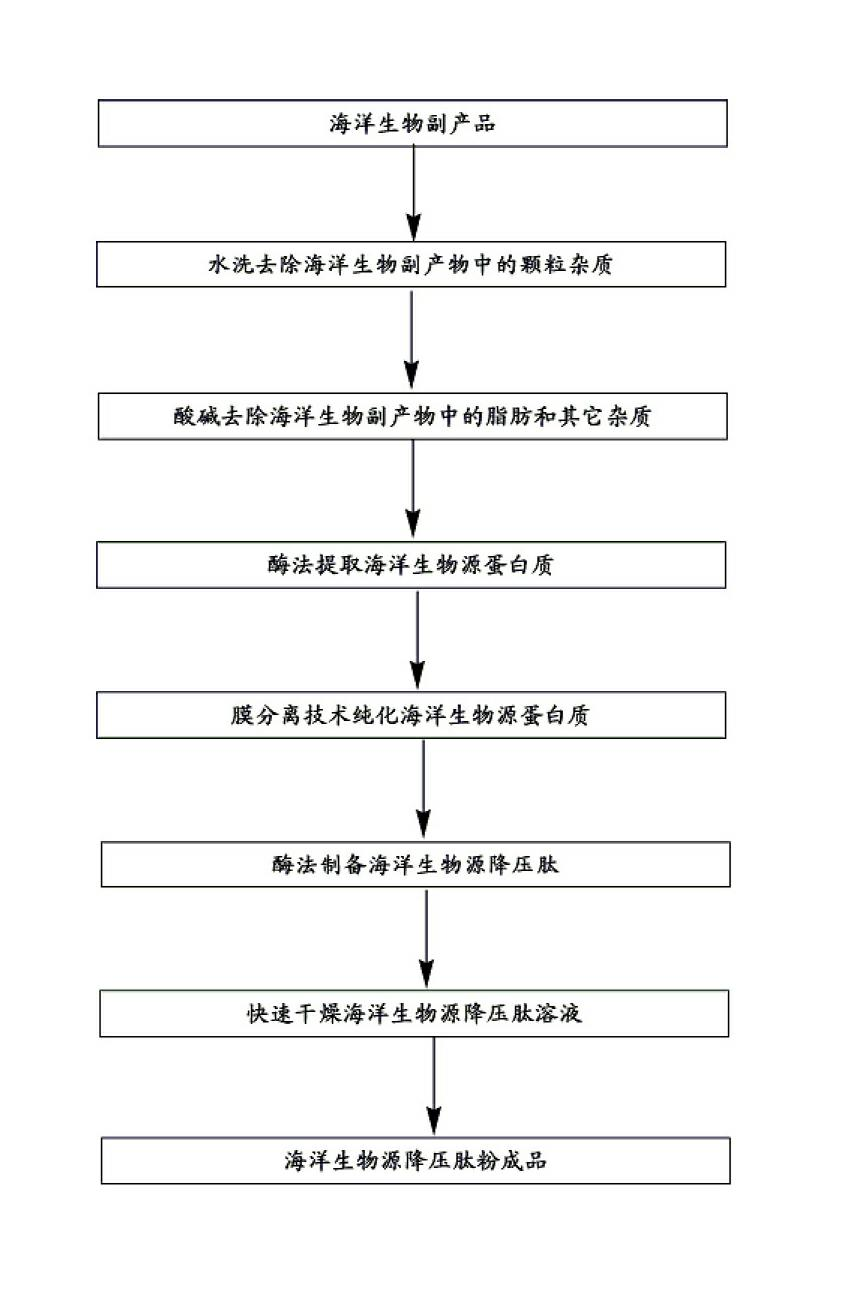

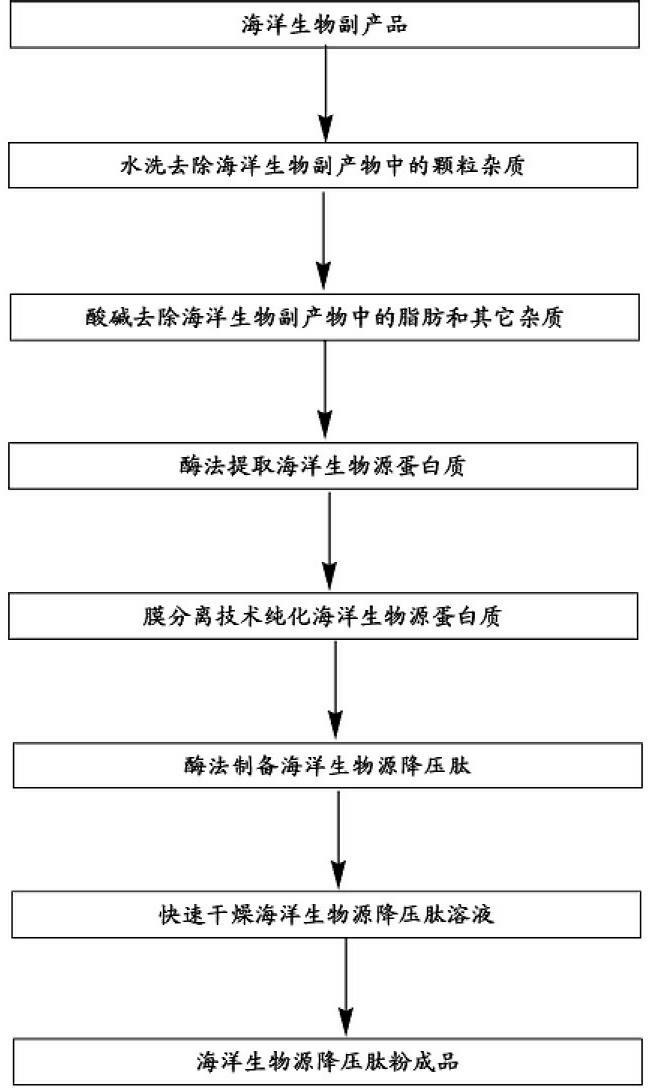

Preparation technique of marine-organism-derived antihypertensive peptides

A marine biology and preparation process technology, applied in the biological field, can solve the problems of small production capacity, high energy consumption and high production cost, and achieve the effects of low cost, high separation efficiency and high depressurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] 1. Use high-quality fish scales as raw materials, and the selected fish scales can be marine fish scales or freshwater fish scales. Get 500kg of fish scales and drop into the stirring washer, add 5000kg of water, wash 3 times, and remove particle impurities. Put the washed fish scales into a cleaning machine, add 5000 kg of a mass volume concentration of 5% sodium bicarbonate solution, stir for 11 hours, and wash with water. Add 5000kg volume percent concentration and be 5% hydrochloric acid solution, stir for 8 hours, wash with water, remove sticky substance, fat and other impurities on the fish scale surface.

[0039] 2. Put the cleaned fish scales in the reaction kettle, add 5000kg of water, add 3kg of pepsin, adjust the pH value with sodium hydroxide and sulfuric acid, and control the pH of the reaction system to 1.5, enzymatic hydrolysis temperature 50 ℃, enzymatic hydrolysis After 6 hours, after the enzymatic hydrolysis reaction, the temperature was raised to 80°...

example 2

[0045] 1. Use high-quality fish scales as raw materials, and the selected fish scales can be marine fish scales or freshwater fish scales. Get 500kg of fish scales and drop into the stirring washer, add 5000kg of water, wash 3 times, and remove particle impurities. Put the washed fish scales into a cleaning machine, add 5000 kg of a mass volume concentration of 5% sodium bicarbonate solution, stir for 11 hours, and wash with water. Adding 5000kg volume percent concentration is 5% sulfuric acid solution, stirs 8 hours, washes with water, removes sticky matter, fat and other impurities on the fish scale surface.

[0046] 2. Put the washed fish scales in the reaction kettle, add 5000kg of water, add 1.5kg of pepsin, use sodium hydroxide and hydrochloric acid to adjust the pH value, and control the pH of the reaction system to 1, the enzymatic hydrolysis temperature is 40°C, and the enzyme After 6 hours of hydrolysis, after the end of the enzymatic hydrolysis reaction, the temper...

example 3

[0052] 1. Use high-quality fish scales as raw materials, and the selected fish scales can be marine fish scales or freshwater fish scales. Get 500kg of fish scales and drop into the stirring washer, add 5000kg of water, wash 3 times, and remove particle impurities. Put the washed fish scales into a cleaning machine, add 5000 kg of 1% sodium hydroxide solution, stir for 11 hours, and wash with water. Add 5000kg volume percent concentration and be 1% hydrochloric acid solution, stir 9 hours, wash with water, remove sticky substance, fat and other impurities on the fish scale surface.

[0053] 2. Put the cleaned fish scales in the reaction kettle, add 5000kg of water, add 4.5kg of acid protease, use sodium hydroxide and sulfuric acid to adjust the pH value, and control the pH of the reaction system to 2.5, the enzymatic hydrolysis temperature is 40°C, and the enzyme After 3 hours of hydrolysis, after the end of the enzymatic hydrolysis reaction, the temperature was raised to 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com