Zinc and fluorine-doped carbon-coated lithium manganese phosphate cathode material and preparation method thereof

A technology of carbon-coated lithium manganese phosphate and positive electrode materials, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of low actual capacity and poor cycle performance, and achieve large-scale production, easy control, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

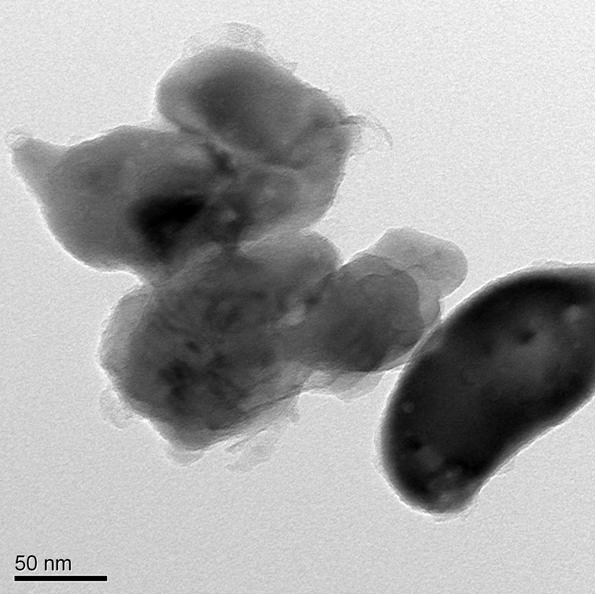

[0028] Accurately weigh 0.1 mol lithium hydroxide, 0.09 mol manganese oxalate, 0.01 mol zinc hydroxide, 0.012 mol ammonium fluoride, 0.096 mol ammonium dihydrogen phosphate, and 10 g citric acid, mix them evenly, and put them into the ball mill tank of the planetary ball mill , Then add 30 ml of deionized water as the mixing medium, ball mill for 6 hours, the ball mill mixes evenly into the precursor of the rheological phase state, put the precursor in the rheological phase state in the tube furnace, under the protection of high-purity nitrogen Calcined, heated to 650°C at a heating rate of 2°C / min, kept for 15 hours, and cooled to room temperature with the furnace to obtain a zinc- and fluorine-doped carbon-coated lithium manganese phosphate cathode material LiZn 0.1 Mn 0.9 (PO 4 ) 0.96 F 0.12 / C (The XRD pattern of the zinc and fluorine doped carbon-coated lithium manganese phosphate cathode material is shown in figure 1 ).

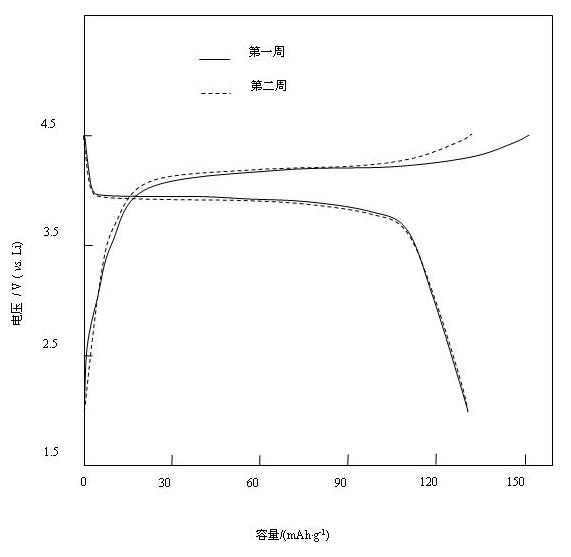

[0029] Coating the synthesized zinc and fluorine-dope...

Embodiment 2

[0031] Accurately weigh out 0.094mol lithium acetate, 0.095mol manganese acetate, 0.005mol zinc acetate, 0.006mol lithium fluoride, 0.098mol ammonium hydrogen phosphate, and 12 g polyethylene glycol, mix them evenly and put them into the ball mill tank of the planetary ball mill. Then add 35 ml of ethanol as the mixing medium, ball mill for 4 hours, the ball mill mixes evenly into the precursor in the rheological phase state, put the precursor in the rheological phase state in a tube furnace, and calcine under the protection of high-purity argon. Heat to 750°C at a heating rate of 4°C / min, keep it for 12 hours, and then cool down to room temperature with the furnace to obtain a zinc- and fluorine-doped carbon-coated lithium manganese phosphate cathode material LiZn 0.05 Mn 0.95 (PO 4 ) 0.98 F 0.06 / C.

[0032] Coating the synthesized zinc and fluorine-doped carbon with LiZn as the cathode material of lithium manganese phosphate 0.05 Mn 0.95 (PO 4 ) 0.98 F 0.06 / C is mixed with ace...

Embodiment 3

[0034] Accurately weigh out 0.05mol lithium carbonate, 0.085mol manganese acetate, 0.015mol zinc oxide, 0.009mol ammonium fluoride, 0.097mol ammonium phosphate, 15g glucose, mix them evenly, put them into the ball mill jar of the planetary ball mill, and then add 40ml ring Hexane is used as the mixing medium for 8 hours of ball milling. The ball mill mixes the precursors uniformly into a rheological phase state. The precursors in the rheological phase state are placed in a tube furnace and calcined under the protection of high-purity argon at 5°C. The heating rate is heated to 850℃ / min, kept for 8 hours, and then cooled to room temperature with the furnace to obtain the zinc and fluorine-doped carbon-coated lithium manganese phosphate cathode material LiZn 0.15 Mn 0.85 (PO 4 ) 0.97 F 0.09 / C.

[0035] Coating the synthesized zinc and fluorine-doped carbon with LiZn as the cathode material of lithium manganese phosphate 0.15 Mn 0.85 (PO 4 ) 0.97 F 0.09 / C is mixed with acetylene bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com