Preparation method of sodium ion battery polyanionic composite material

A polyanion type, sodium ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity and low electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] DETAILED DESCRIPTION OF THE INVENTION The present embodiment is a method for preparing a sodium ion battery polyanionic composite material, specifically, according to the following steps:

[0037] First, the complexing agent is dissolved in deionized water, then the sodium source, manganese source, chromium source, and phosphate source are added, stirred from 0.5 h to 1 h, then add titanium source, then stand 2 h ~ 3h to expand, Sol;

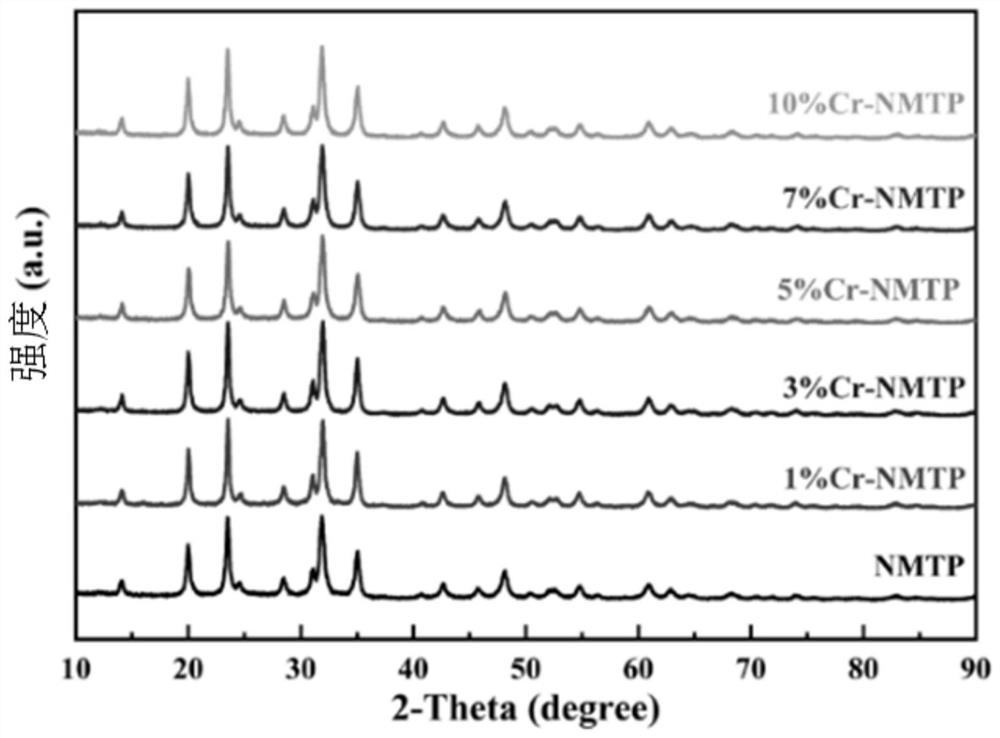

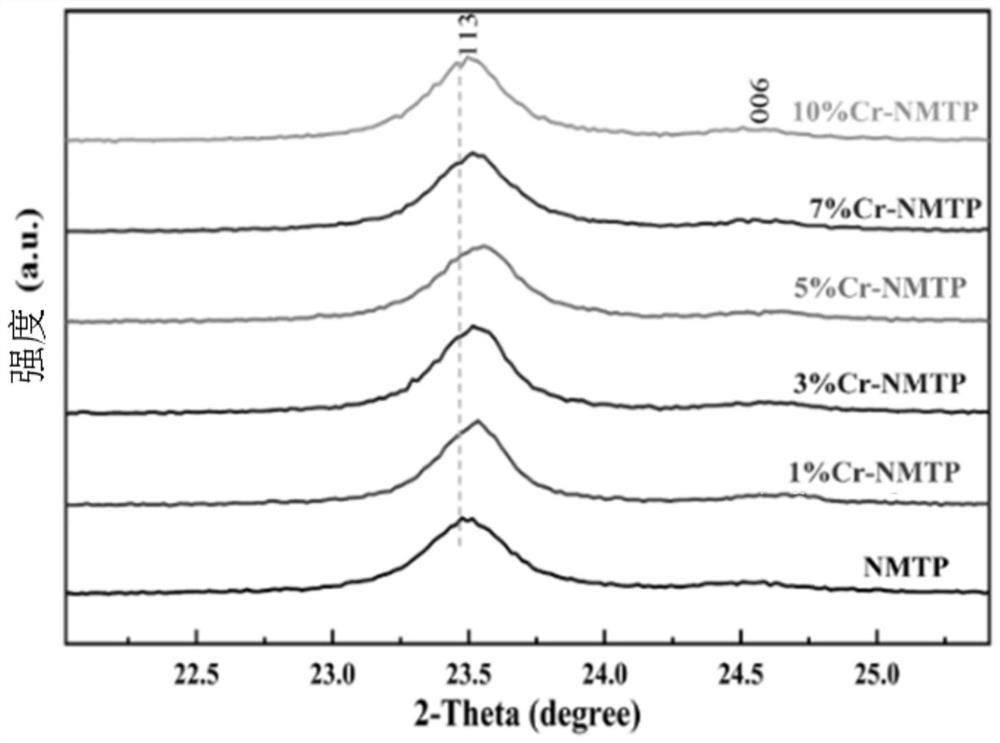

[0038] The sodium elements in the sodium source, manganese elements in manganese sources, chromium elements in chromium sources, phosphate and titanium elements in the phosphate source in phospologists, in order (3 to 3.2) :( 3 to 3.2) :( 3 ~ 3.2) :( 1-x): x: 3: 1 Perform ratio, X is 0.01 ~ 0.15;

[0039] The ratio of the molar amount of the complexing agent and the molar amount of manganese element, chromium element, and titanium elements are (1 to 2): 1;

[0040] Second, the solution obtained by the step is stirred into the gel shape in a w...

specific Embodiment approach 2

[0043] DETAILED DESCRIPTION OF THE INVENTION Different embodiments of the present embodiment are different: The complexing agent described in step one is a mixture of citric acid, oxalic acid, ascorbic acid and sucrose, and as a carbon source Complexer. Others are the same as specific embodiments.

specific Embodiment approach 3

[0044] BEST MODE FOR CARRYING OUT THE INVENTION 3: The present embodiment is different from that of the particular embodiment: the manganese sources described in the step one are tetrahydrate acetate. Others are the same as those of the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com