Improved drilling fluid with high-strength wall protection effect and preparation method thereof, and equipment

A drilling fluid, an improved technology, applied in separation methods, chemical instruments and methods, drilling compositions, etc., can solve the problems of large water loss, poor economy, low viscosity, etc., to reduce water loss and stop leaks Good effect, high viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

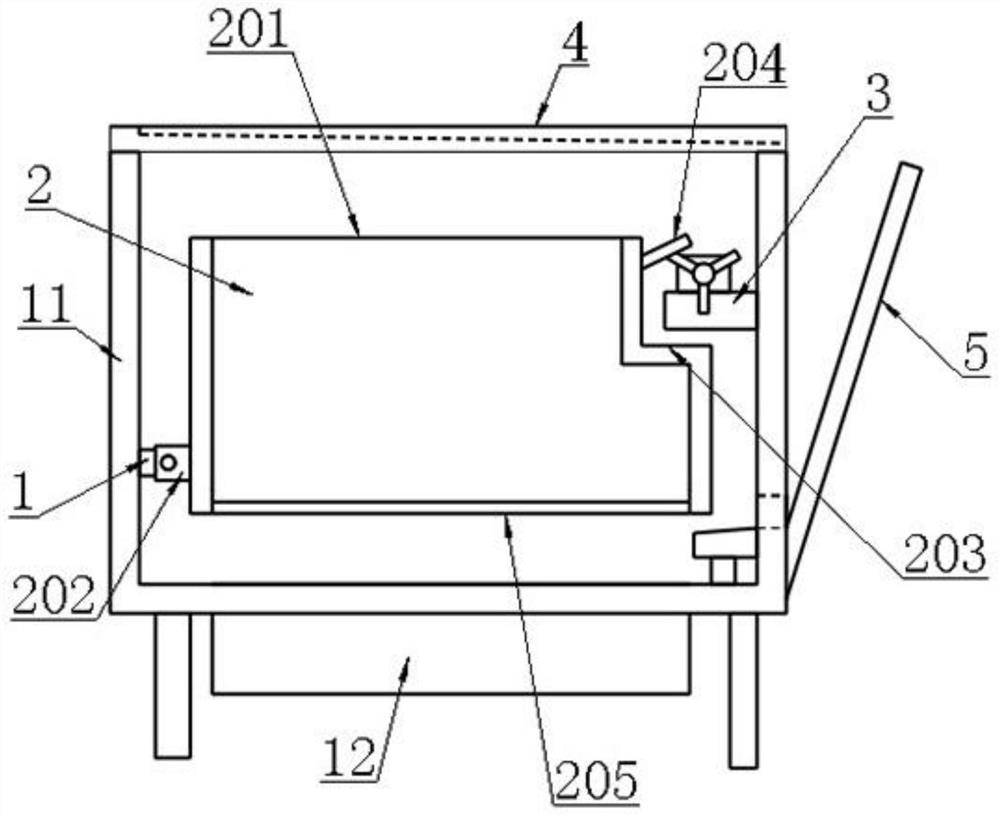

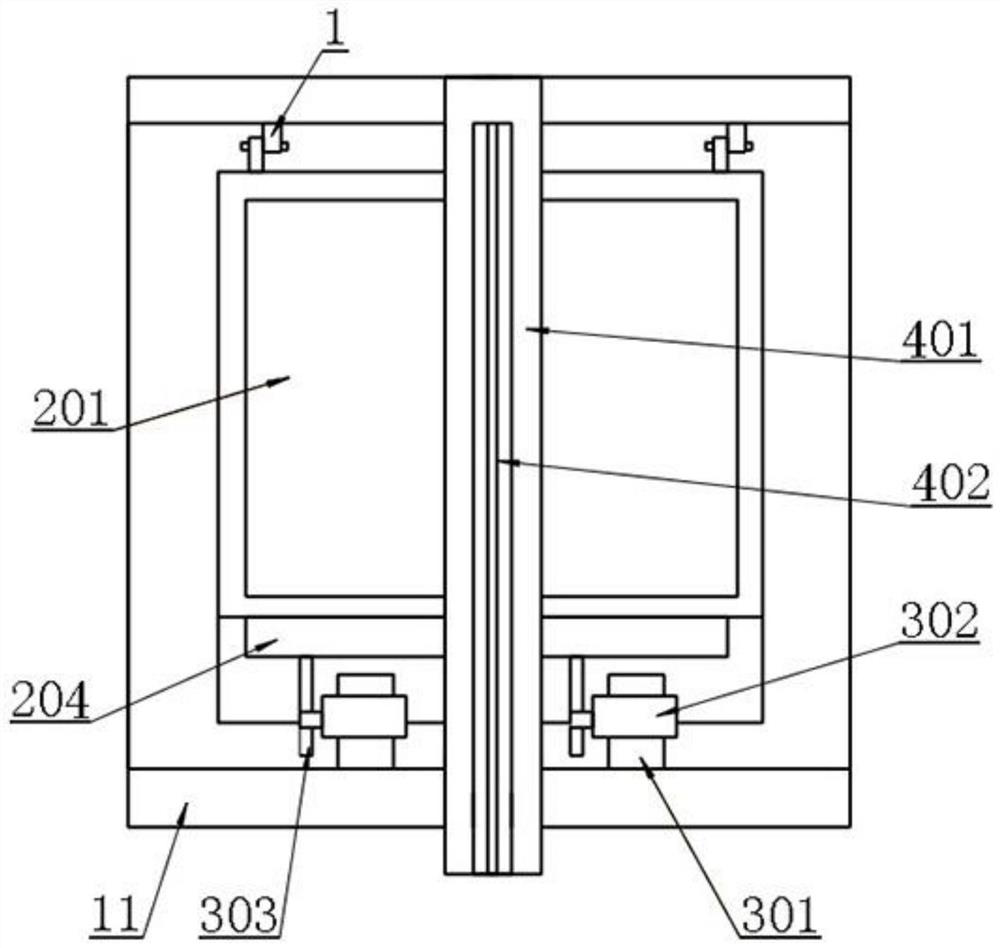

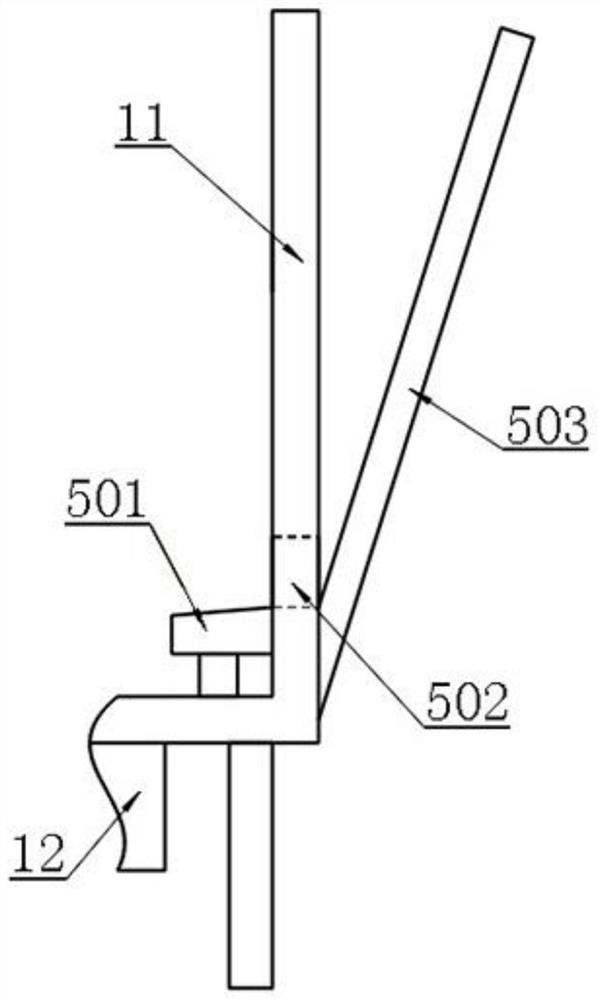

[0040] Example: as attached figure 1 , 2 As shown in , 3, 4 and 5, an improved drilling fluid with high-strength wall protection, its material composition includes: water, soda ash, bentonite, fluid loss reducer, suspension accelerator and plugging agent, each by weight The components are as follows: 900-1000 parts of water, 3-5 parts of soda ash, 35-40 parts of bentonite, 2-5 parts of fluid loss reducer, 3-6 parts of suspension accelerator, and 15-25 parts of plugging agent.

[0041] Specifically, the drilling fluid includes the following components by weight: 1000 parts of water, 5 parts of soda ash, 40 parts of bentonite, 3.5 parts of fluid loss reducer, 4 parts of suspension accelerator, and 20 parts of plugging agent.

[0042] The preparation method of drilling fluid comprises the following steps in sequence:

[0043] S1, add 1000kg of water in the stirred tank, then add 5kg of soda ash to obtain a solvent system with a pH of 8.5;

[0044] S2, add 40kg bentonite in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com