Device for absorbing and separating oil fouling of biomass boiler

A biomass boiler, adsorption separation technology, which is applied in the combined device, separation method, dispersed particle separation and other directions, can solve the problems of low work efficiency, paste bag, filter bag losing filtering effect, etc., and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

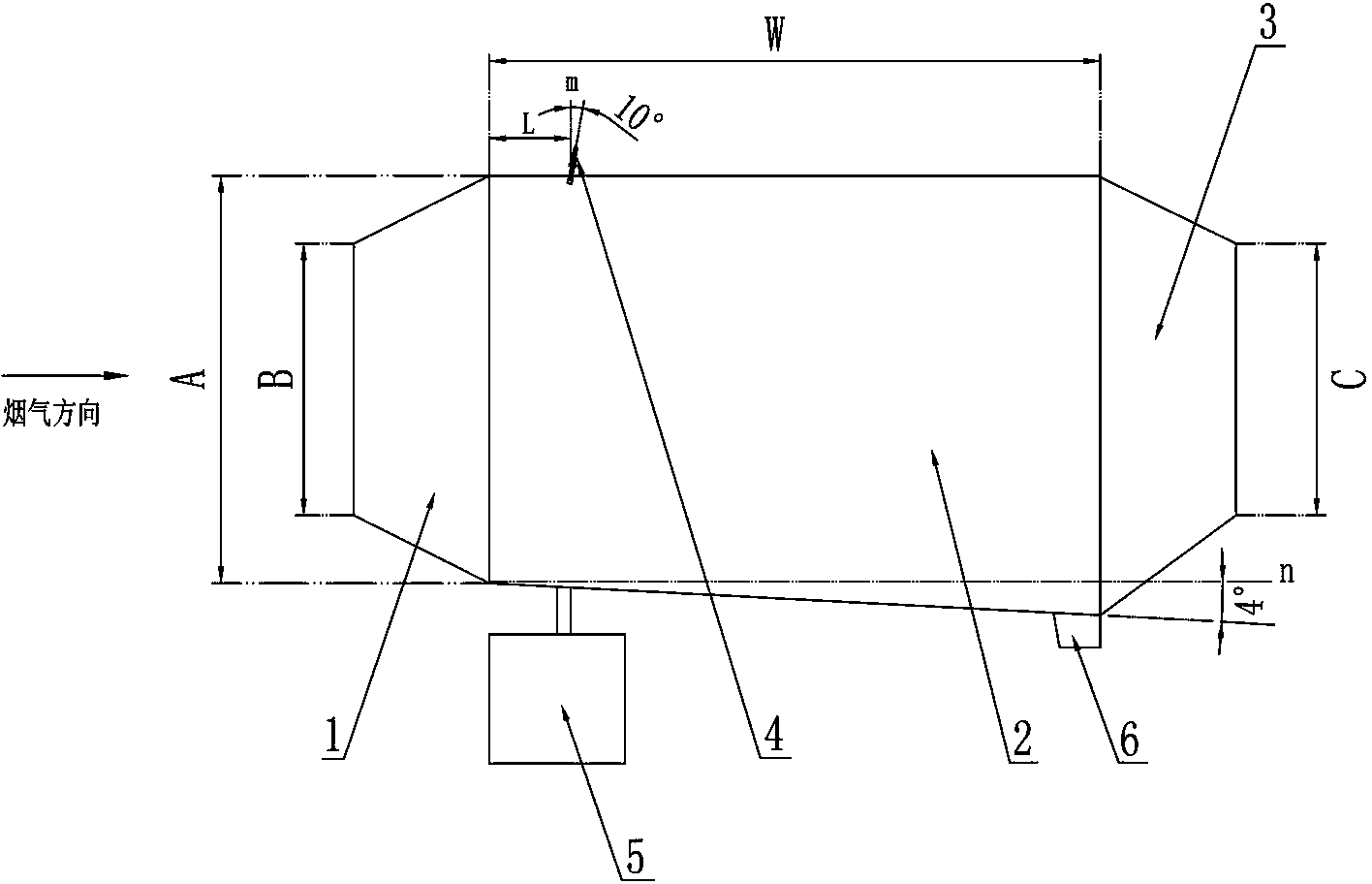

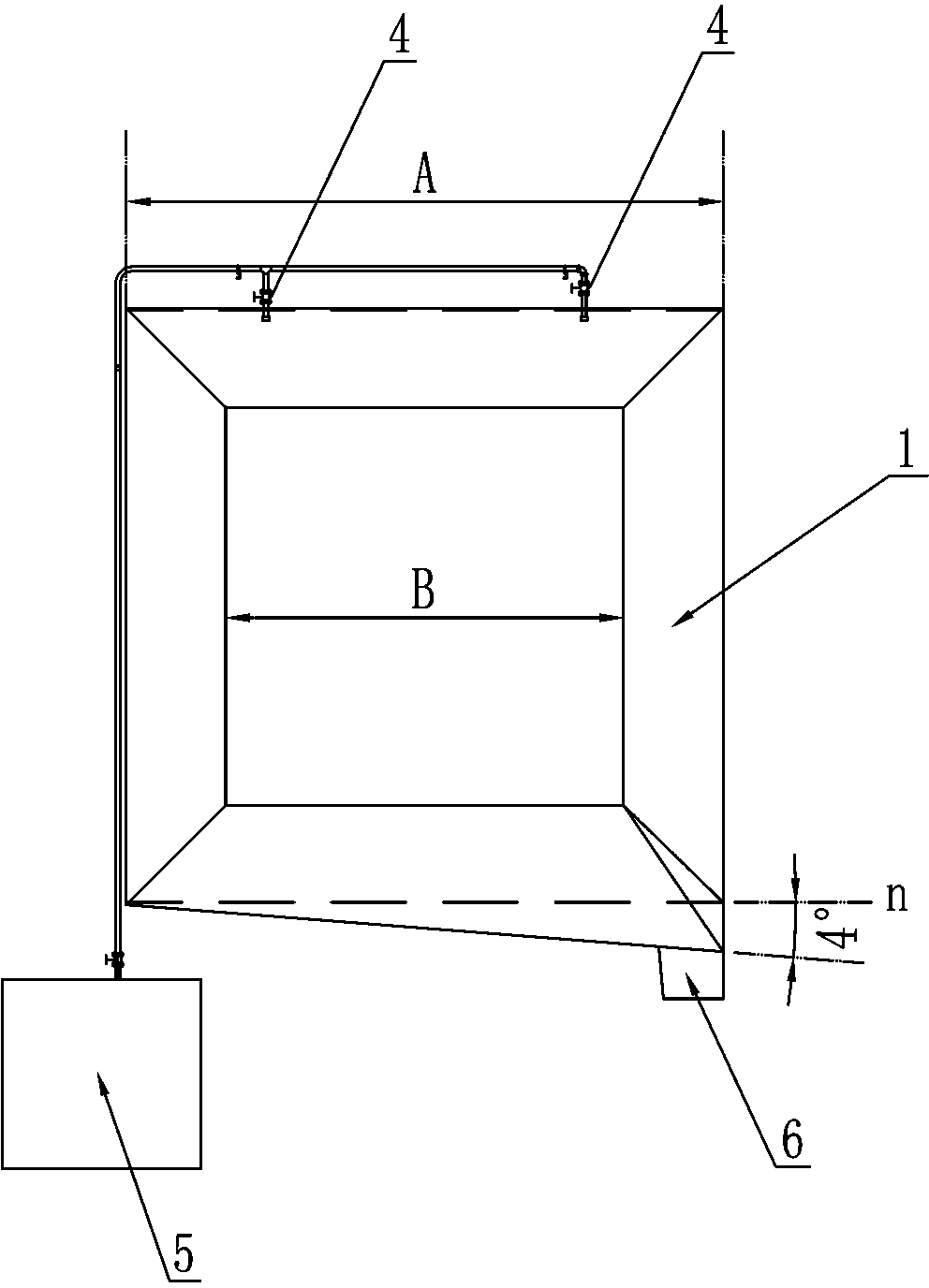

[0016] Such as figure 1 , figure 2 As shown, the described a kind of biomass boiler oil adsorption and separation device includes an oil separation pipe body, and the oil separation pipe body is composed of a flue gas inlet pipe section 1, an oil pollution separation pipe section 2 and a flue gas outlet pipe section 3 connected in sequence. The gas inlet pipe section 1 is arranged in the shape of a trumpet whose pipe diameter gradually increases along the direction of flue gas advancement, and the flue gas outlet pipe section 3 is arranged in the shape of a trumpet whose pipe diameter gradually decreases along the direction of flue gas advancement, outside the oil separation pipe section 2 A number of spray pipes 4 are evenly arranged on the wall, and the nozzles of all spray pipes 4 extend into the oil pollution separation pipe section 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com