Garbage leachate treatment technique

A landfill leachate and treatment process technology, applied in the field of sewage treatment process, can solve the problems of reduced biodegradability, infeasibility, difficulty in meeting discharge standards, etc., and achieve the effect of stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

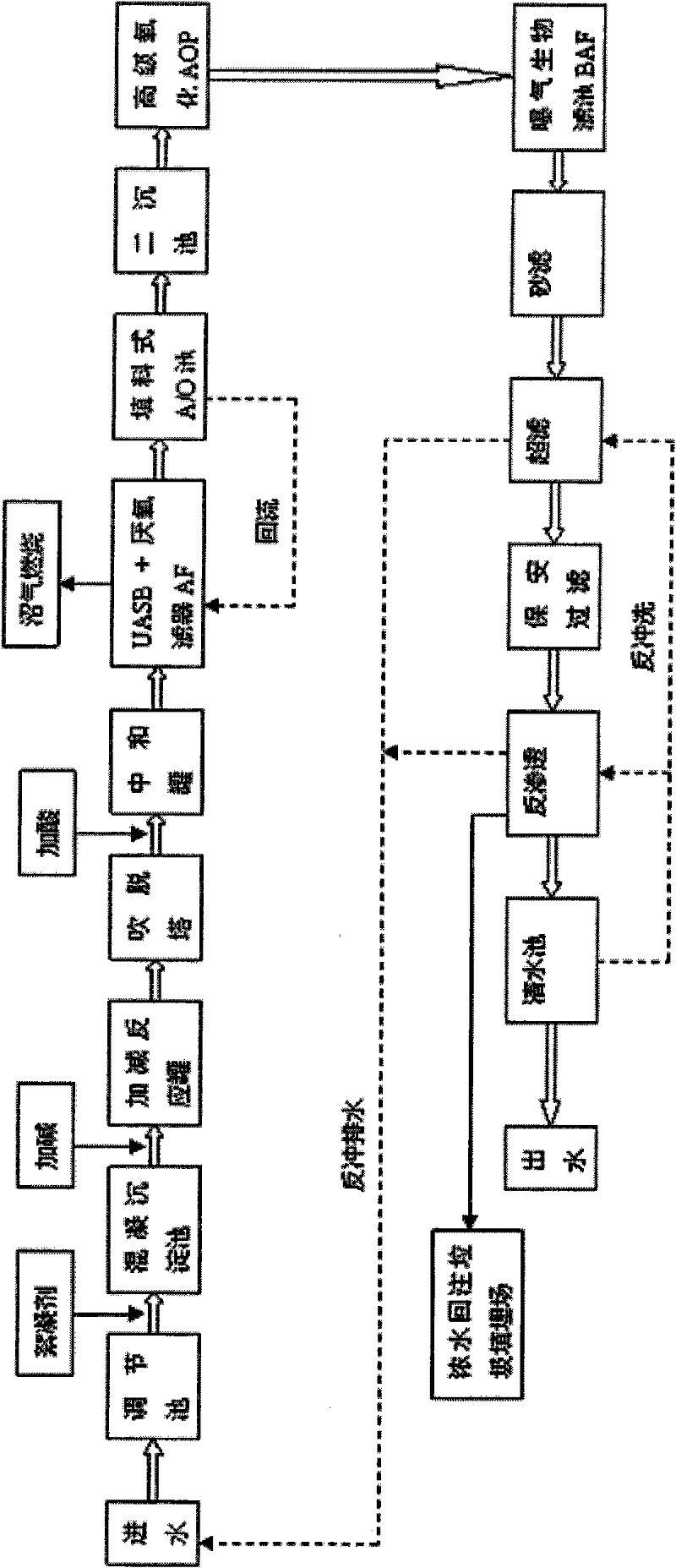

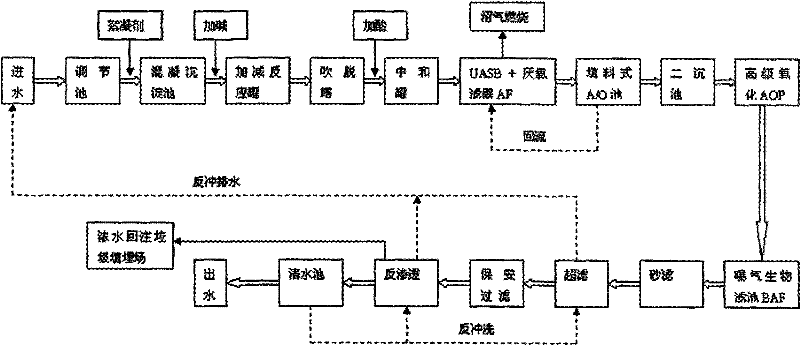

[0015] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0016] A landfill leachate treatment process adopts the following steps:

[0017] (1) The landfill leachate is homogenized and the water volume is adjusted through the regulating tank;

[0018] (2) Add flocculant to the landfill leachate in the pipeline between the adjustment tank and the coagulation sedimentation tank, and then the leachate enters the coagulation sedimentation tank to remove most of SS and part of COD;

[0019] (3) The landfill leachate after precipitation enters the alkali-adding reaction tank, and makes the pH to 11.5-12 by adding lime milk solution;

[0020] (4) After the landfill leachate is adjusted to a pH of 11.5-12, it enters the ammonia stripping tower to remove high-concentration ammonia nitrogen to meet subsequent biochemical needs;

[0021] (5) After the ammonia is blown off, the landfill l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com