Self-propagating pyrolysis system applied to solid waste treatment

A self-propagating, pyrolysis technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of difficult cleaning of impurities, difficult processing, unstable impurity content, etc., to achieve short contact time, ensure heat Solution effect, the effect of not wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

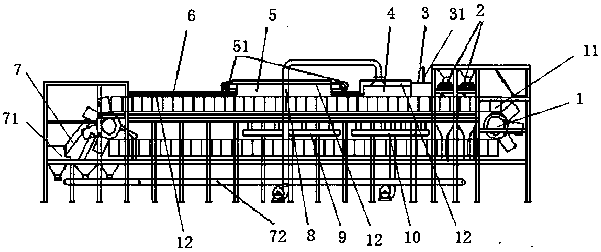

[0041] see figure 1 , the self-propagating pyrolysis system applied to solid waste treatment is composed of a chain-belt conveyor 1, a material distribution device 2, a ventilation loosening device 3, a low-temperature pyrolysis section 4, a self-propagating high-temperature pyrolysis section 5 and a self-propagating pyrolysis section 6 The pyrolysis device of formation, collection and return material device 7 etc. constitute.

[0042] Among them, the chain-belt conveyor 1 adopts the chain-belt conveyor of the metallurgical sintering system, and the chain belt is sequentially assembled with loading trolleys 11 along the running direction to transport the materials.

[0043] The distributing device 2 is located above the machine head of the chain-belt conveyor, and two stages of distributing are arranged successively along the running direction of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com