Iron oxidation product separation and reduction and reduction product storage and transportation system and method

A technology of iron oxidation and production, which is applied in the fields of separation of iron oxidation products, storage and transportation of reduction products, and reduction. It can solve problems such as oxidation and difficulty in iron powder, and achieve the goal of reducing economic losses, reducing economic costs, and improving energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

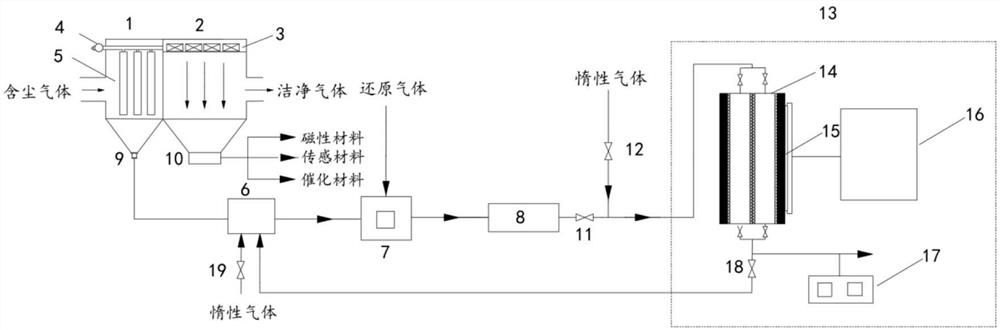

[0024] Such as figure 1 As shown, the present invention is a system for separating, reducing, and storing and transporting iron oxidation products. The system includes a left-right connected primary separator 1 and a secondary separator 2, wherein the primary separator 1 is used for separating and removing In addition to micron α-Fe 2 o 3 Particles, the secondary separator 2 is used to separate and remove nano-scale α-Fe 2 o 3 and γ-Fe 2 o 3Polymer particles; the first-stage separator 1 is provided with a soot blowing device 4 and a filter bag 5 from top to bottom, and the outlet of the bottom of the first-stage separator 1 is provided with a soot discharge valve 9, and the lower part of the ash discharge valve 9 is provided with micron particle powder Bin 6; a fourth valve 19 is provided on the pipe connecting the micron pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com