Measuring device of workpiece rotary table error separation based on double-probe scan data splicing and method thereof

A scanning data and error separation technology, which is applied in the field of workpiece turntable error separation based on the splicing of scanning data of two probes, can solve the problems of large motion error, cannot reflect the surface shape and error of the measured mirror, and achieve the effect of improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

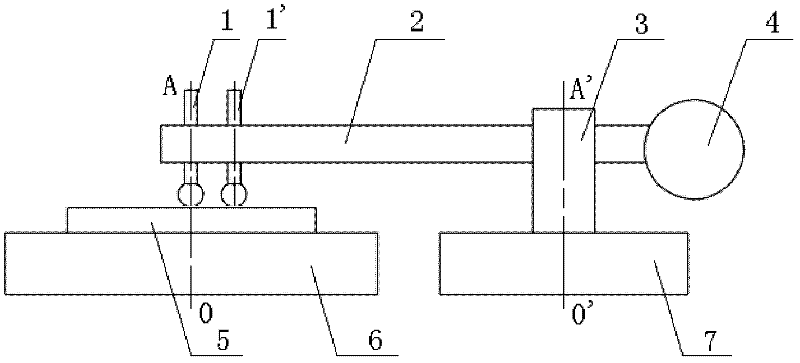

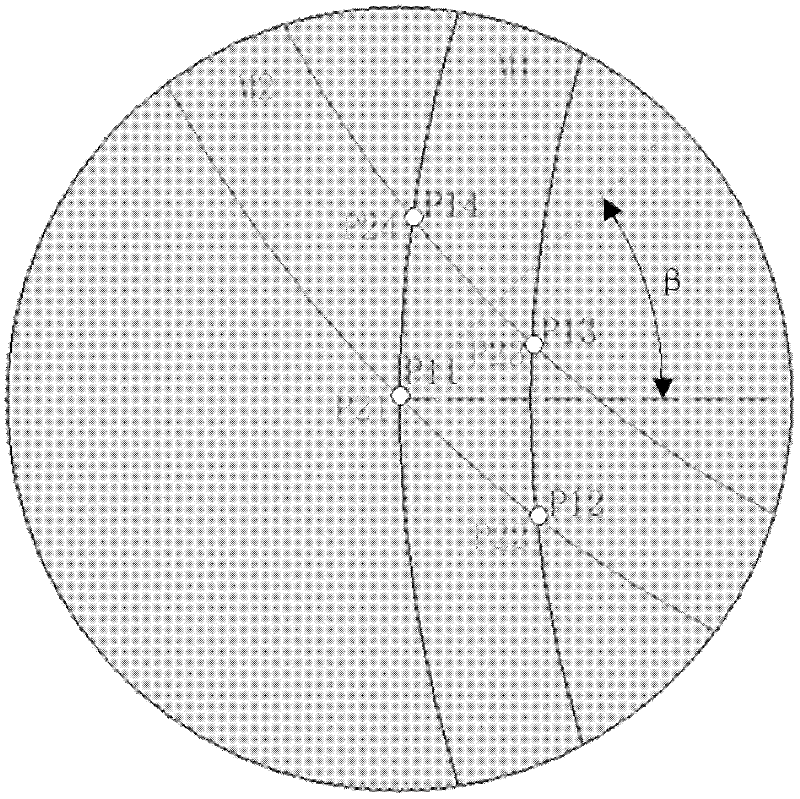

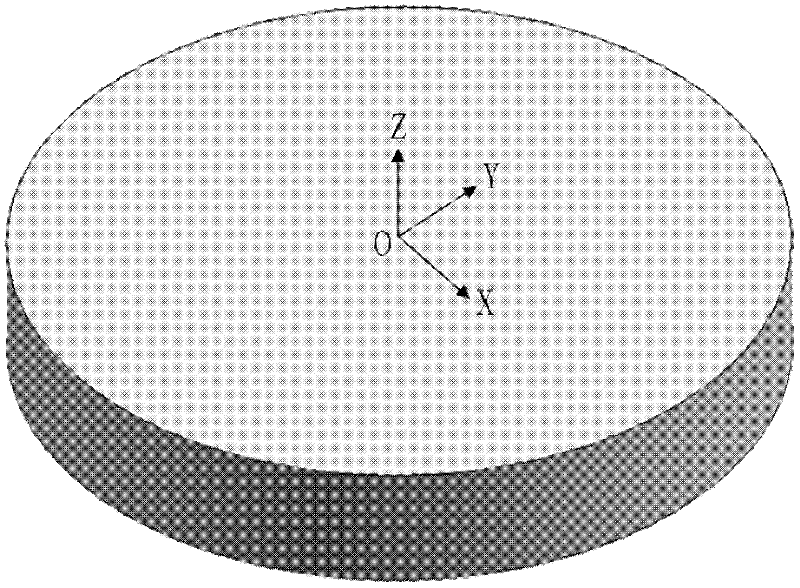

[0035] like figure 1 As shown, it is a schematic diagram of the structure of the device for stitching scanning data of double probes, including probe systems 1 and 1 ′, cross arm 2 , column 3 , counterweight 4 , standard flat crystal 5 , workpiece turntable 6 and cross arm turntable 7 . The probe system 1 is a high-precision contact probe with a resolution of 25nm and a measurement accuracy of 50nm. The cross arm 2 and column 3 are used to connect the cross arm turntable 7 and the measuring head system 1, and complete the rotating movement of the measuring head. The counterweight 4 is used to balance the probe system 1 and the cross arm 2 to ensure that the cross arm turntable 7 maintains a stable rotation. The workpiece turntable 6 is a low-precision turntable, which is used to complete the rotary motion of the standard flat crystal 5 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com