Sand separating and removing device used for powdery material

A sorting technology for powdery materials, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of increasing production costs of enterprises, waste of resources, and inability to recycle boards, etc. Achieve the effect of reducing production cost, improving enterprise benefit and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

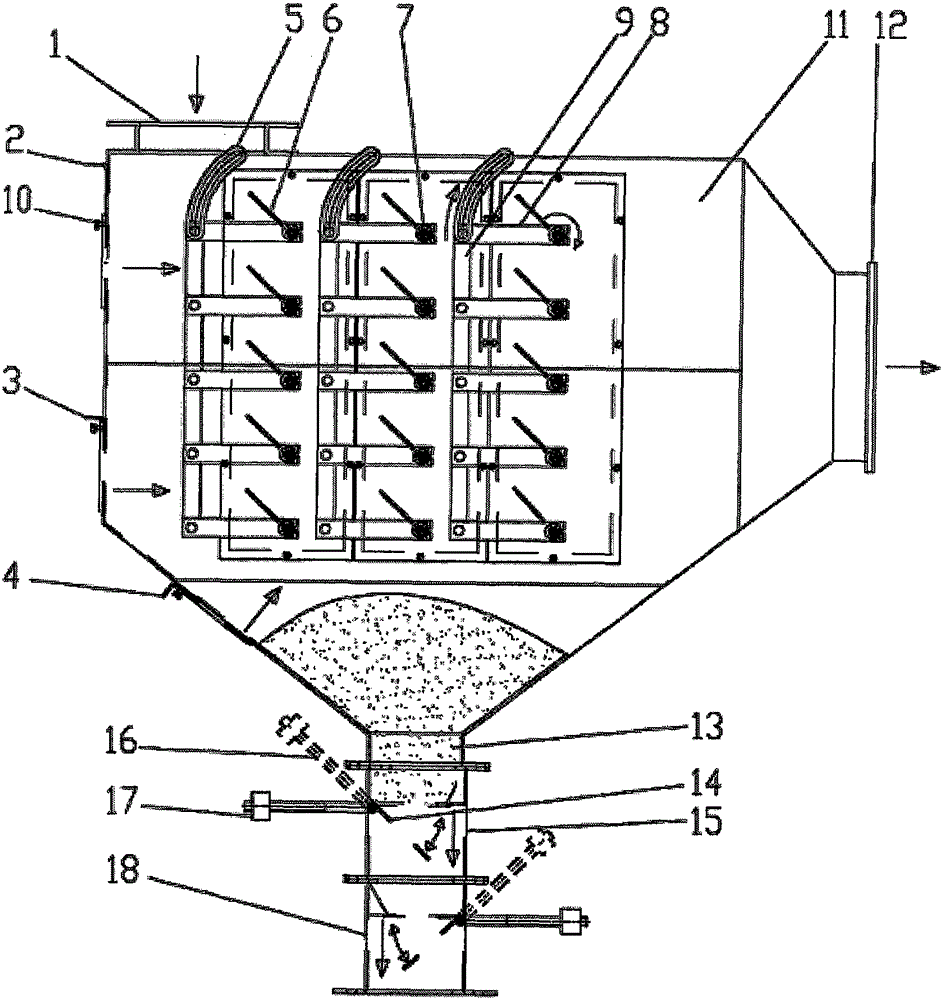

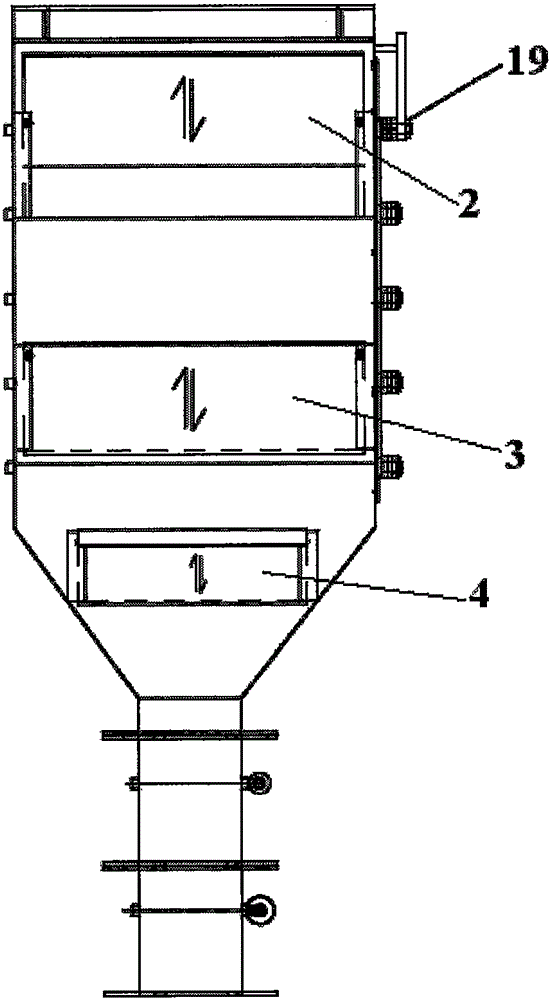

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The structure of the sorting and desandering device used for powdery materials provided by the invention is as follows: figure 1 and figure 2 As shown, it includes a closed box body 11, the top of the box body 11 is provided with a feed port 1, the bottom of the box body 11 is provided with a sand discharge port, and the left and right sides of the box body 11 are respectively provided with air inlet doors and The discharge port 12 and the feed port 1 are located on the top of the box body 11 on the side close to the air inlet door. There are three air inlet doors, which are respectively the upper air inlet door 2, the middle air inlet door 3 and the lower air inlet door 4, and the air inlet door All are provided with the damper chute 10 that is used for adjusting damper size.

[0015] Both the discharge port 12 and the sand discharge port are funnel-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com