Method for refining industrial waste salt

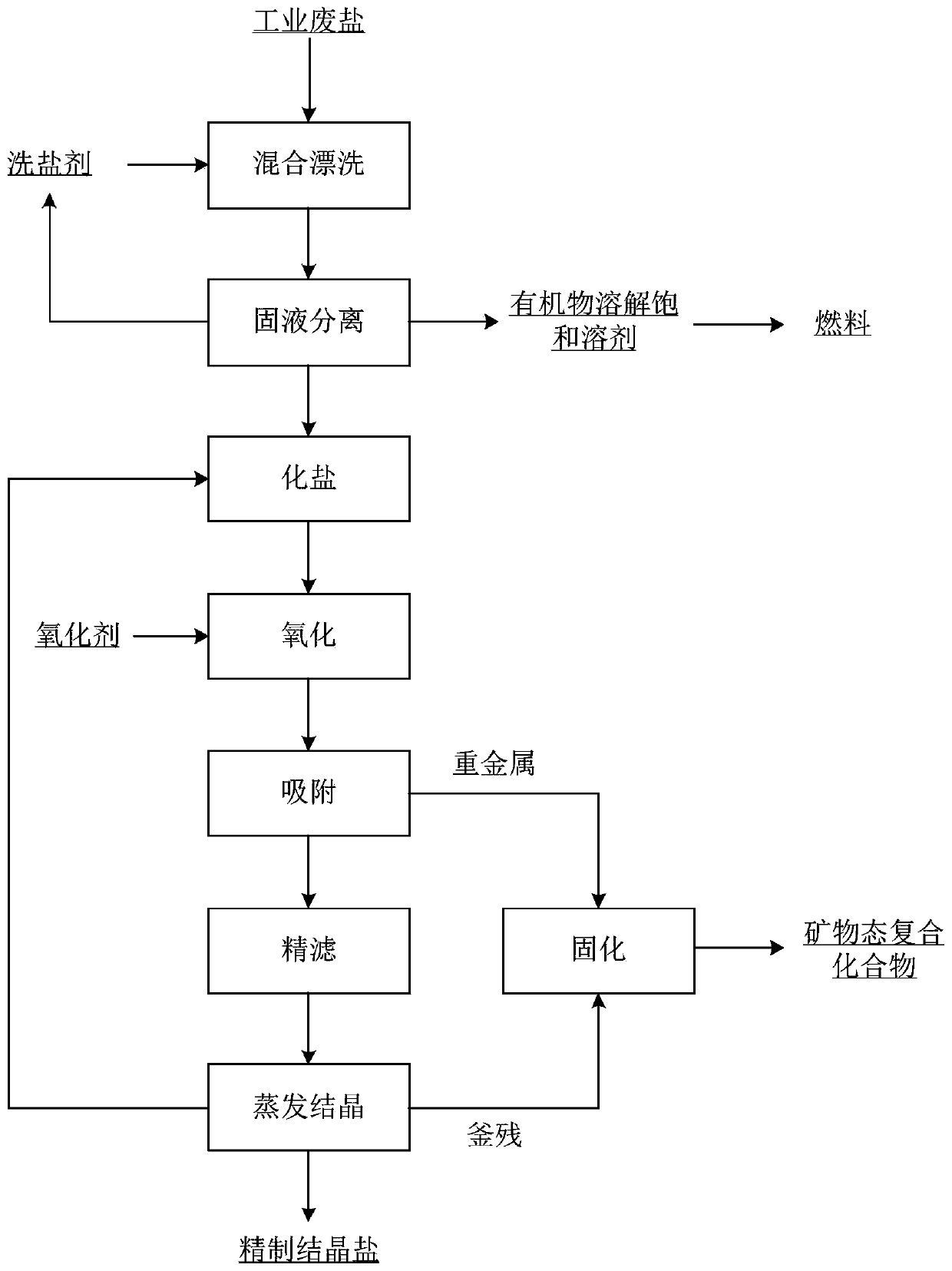

A technology for industrial waste salt and refining treatment, which is applied in the preparation of alkali metal halide shape, alkali metal sulfite/sulfate purification, alkali metal halide purification, etc. Block, high processing cost, low product purity and other problems, to achieve the effect of low cost, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

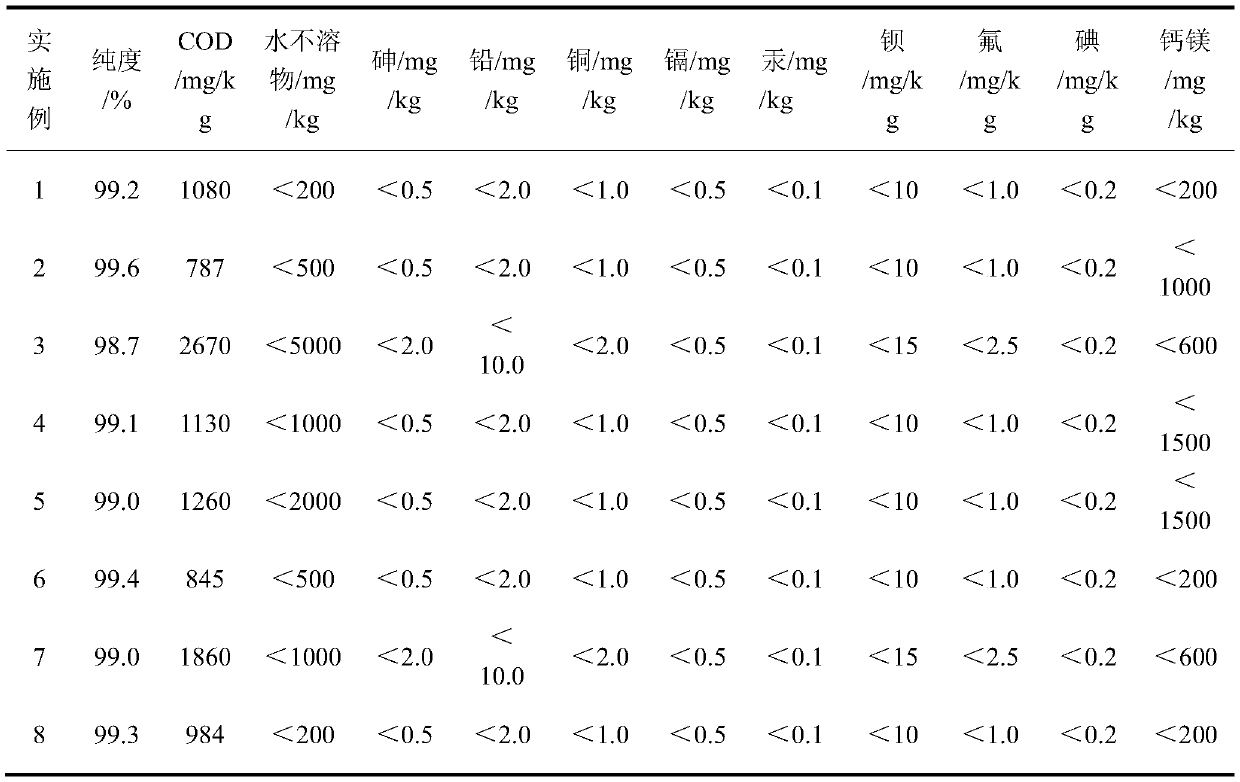

Embodiment 1

[0087] (1) Mix industrial waste salt and salt washing agent and perform pretreatment at 60° C. for 6 hours, and then separate solid and liquid to obtain pretreatment salt and filtrate; the industrial waste salt is sodium chloride waste salt; the The content of salt in the industrial waste salt is 80%; the salt washing agent is ethanol; the volume to mass ratio of the salt washing agent and industrial waste salt is 6:1; the pretreatment is rinsing; the rinsing method is Stir and rinse;

[0088] (2) The pretreatment salt obtained in step (1) is subjected to chemical salts, followed by oxidation treatment to obtain a primary treatment solution; the mass concentration of the salt solution after chemical salts in the chemical salts is 20wt%; the oxidation treatment method adopts Stepwise oxidation; the stepwise oxidation includes preliminary oxidation and deep oxidation; the oxidant used in the preliminary oxidation is sodium peroxide; the oxidant used in the deep oxidation is sodi...

Embodiment 2

[0093] (1) Mix industrial waste salt and washing salt agent and perform pretreatment at 20°C for 1 hour, and then separate solid and liquid to obtain pretreatment salt and filtrate; the industrial waste salt is sodium sulfate waste salt; the industrial waste salt is The content of salt in the waste salt is 97%; the salt washing agent is methanol; the volume to mass ratio of the salt washing agent and industrial waste salt is 1:1; the pretreatment is rinsing; the rinsing method is stirring rinsing;

[0094] (2) The pretreatment salt obtained in step (1) is subjected to chemical salting, followed by oxidation treatment to obtain a primary treatment solution; the mass concentration of the salt solution after chemical salting in the chemical salt is 30wt%; the oxidation treatment method adopts Stepwise oxidation; the stepwise oxidation includes preliminary oxidation and deep oxidation; the oxidant used in the preliminary oxidation is hydrogen peroxide and ozone; the oxidant used i...

Embodiment 3

[0099] (1) Mix industrial waste salt and salt washing agent and perform pretreatment at 10°C for 12 hours, and then separate solid and liquid to obtain pretreatment salt and filtrate; the industrial waste salt is sodium chloride waste salt; the The content of salt in the industrial waste salt is 50%; the salt washing agent is petroleum ether; the volume to mass ratio of the salt washing agent and industrial waste salt is 10:1; the pretreatment is rinsing; the rinsing method It is one of suspension rinsing;

[0100] (2) carry out the pretreatment salt that step (1) obtains to salt, carry out oxidation treatment afterwards, obtain primary treatment liquid; In described salt, the mass concentration of salt solution after salt is 25wt%; Described oxidation treatment mode adopts Step-by-step oxidation; said step-by-step oxidation includes preliminary oxidation and deep oxidation; said preliminary oxidation used oxidant is peracetic acid and oxygen; said deep oxidation used oxidant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com