Chip and film separation device

A separation device and membrane technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of poor label separation effect, difficult adjustment and control of air volume, etc., and achieve simple structure , the effect of effective separation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

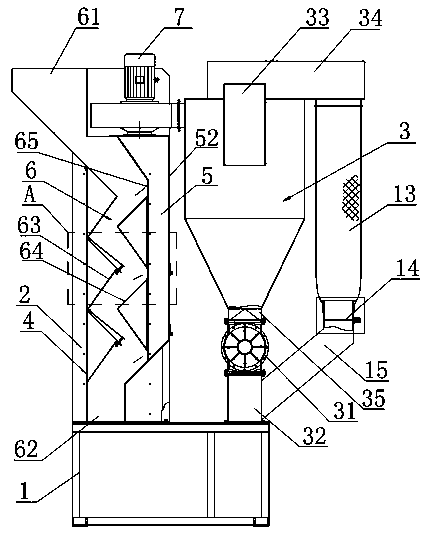

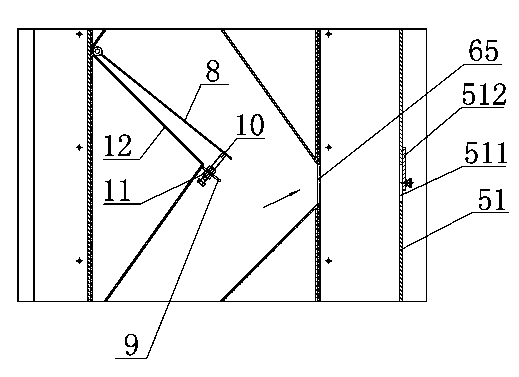

[0014] Such as figure 1 , figure 2 As shown, the sheet membrane separation device includes a separation box 2 supported on a frame 1 and a cyclone separator 3. The cyclone separator 3 is a separation device widely used in industry, and it uses centrifugal force to separate solids in the airflow. Particles, its structure includes: a cylinder body and a conical part arranged at the lower end of the cylinder body, the small opening at the bottom of the conical part is the discharge port 35 for the solid particles of the cyclone separator 3, and an air outlet 33 is arranged at the center of the upper end of the cylinder body , during work, after the airflow containing solid particles enters the cylindrical body of the cyclone separator 3, it rotates along the inner wall of the cylindrical body while descending along the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com