Integrated super-gravity separation device

A separation device and super-gravity technology, which are applied in combination devices, separation methods, dispersed particle separation, etc., can solve the problems of low separation efficiency of super-gravity rotating packed bed, gas easily entrained liquid, solid particles, good or bad effect, etc. Compact structure, improved flood point, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

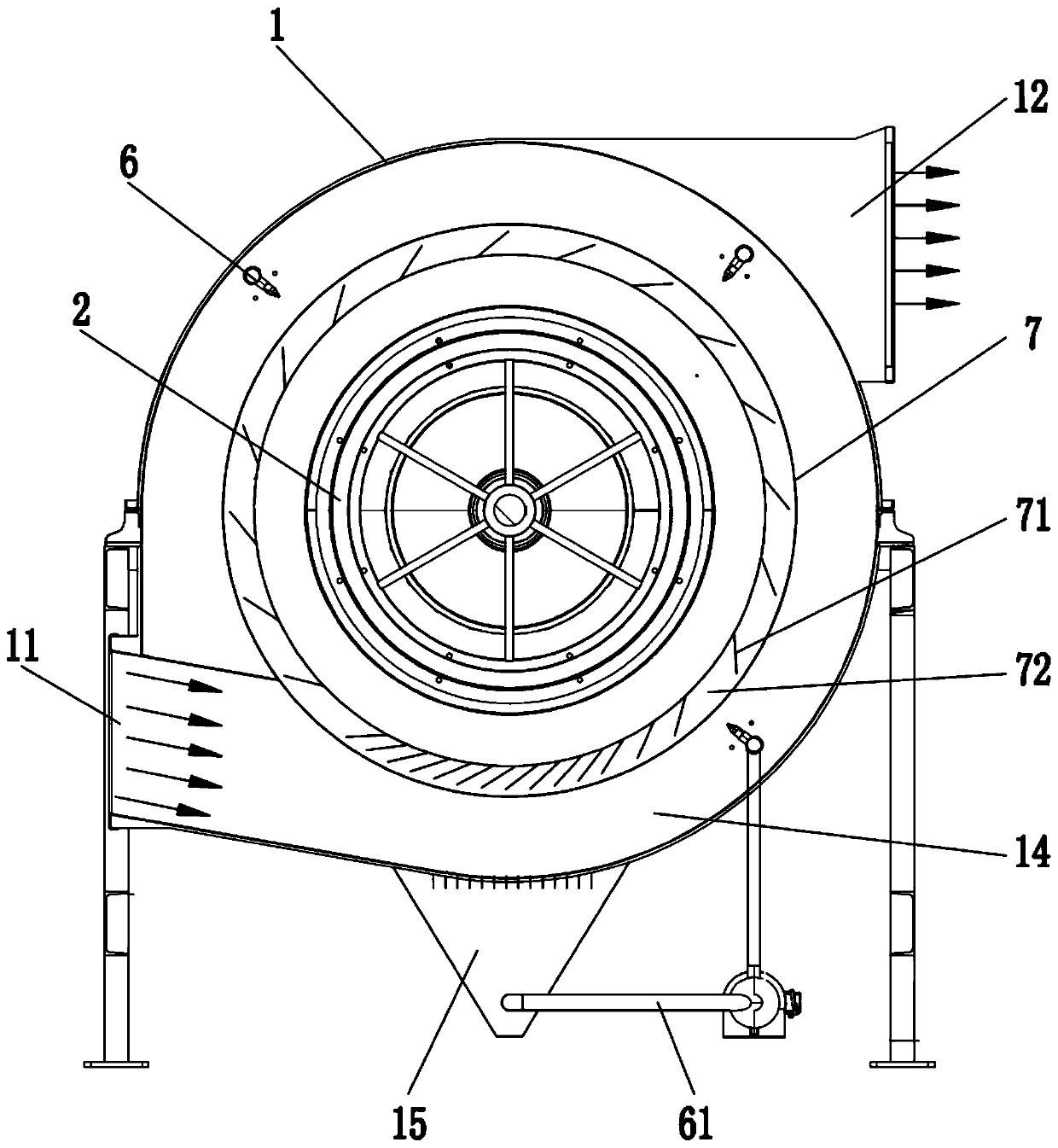

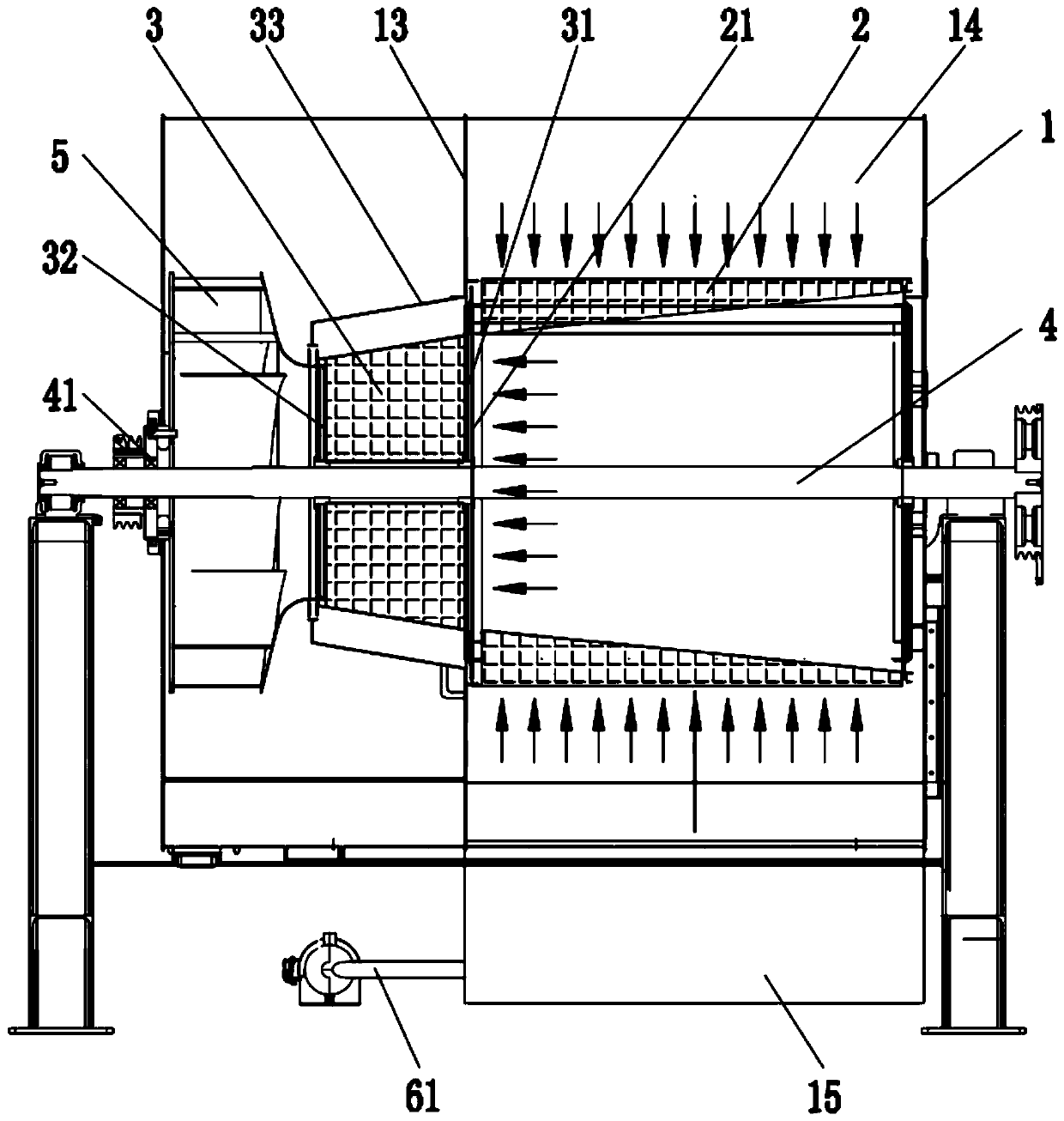

[0049] Such as Figure 1 to Figure 4 As shown, an integrated supergravity separation device mainly includes a housing 1, a counter-current rotating packing layer 2 and a cross-flow rotating packing layer 3; the housing 1 is provided with an air inlet 11 and an air outlet 12; the counter-current rotating packing layer 2 and the The cross-flow rotating packing layer 3 is both rotatably arranged in the housing 1; the air inlet 11 is connected to the circumferential peripheral area of the counter-current rotating packing layer 2, and the axial center gas phase outlet port 21 of the counter-current rotating packing layer 2 is connected to the cross-flow The axial inlet port 31 of the rotating packing layer 3 and the axial gas phase outlet port 32 of the cross-flow rotating packing layer 3 communicate with the air outlet 12 .

[0050] Specifically, the counter-current rotating packing layer 2 and the cross-flow rotating packing layer 3 are coaxially connected to the main rotating ...

Embodiment 2

[0066] Such as Figure 5 As shown, the difference from Embodiment 1 is that both ends of the rotating axial direction of the counter-current rotating packing layer 2 are provided with an axial central gas phase outlet port 21, and the cross-flow rotating packing layer 3 rotates when the counter-current rotating packing layer 2 There is one at both ends of the axial direction, and two air outlets 12 are provided on the housing 1 and communicate with the axial gas phase outlet port 32 of a counter-current rotating packing layer 2 respectively, and the fan 5 is also provided in each counter-current rotating packing layer. Two axial gas phase outlets 32 are provided respectively, and the air inlet 11 on the casing 1 is arranged at the middle position close to the rotation axis of the counter-current rotating packing layer 2, and the dust-laden gas is rotated from the counter-current rotating packing layer 2 to the middle area of the axial direction. The flow is divided to both e...

Embodiment 3

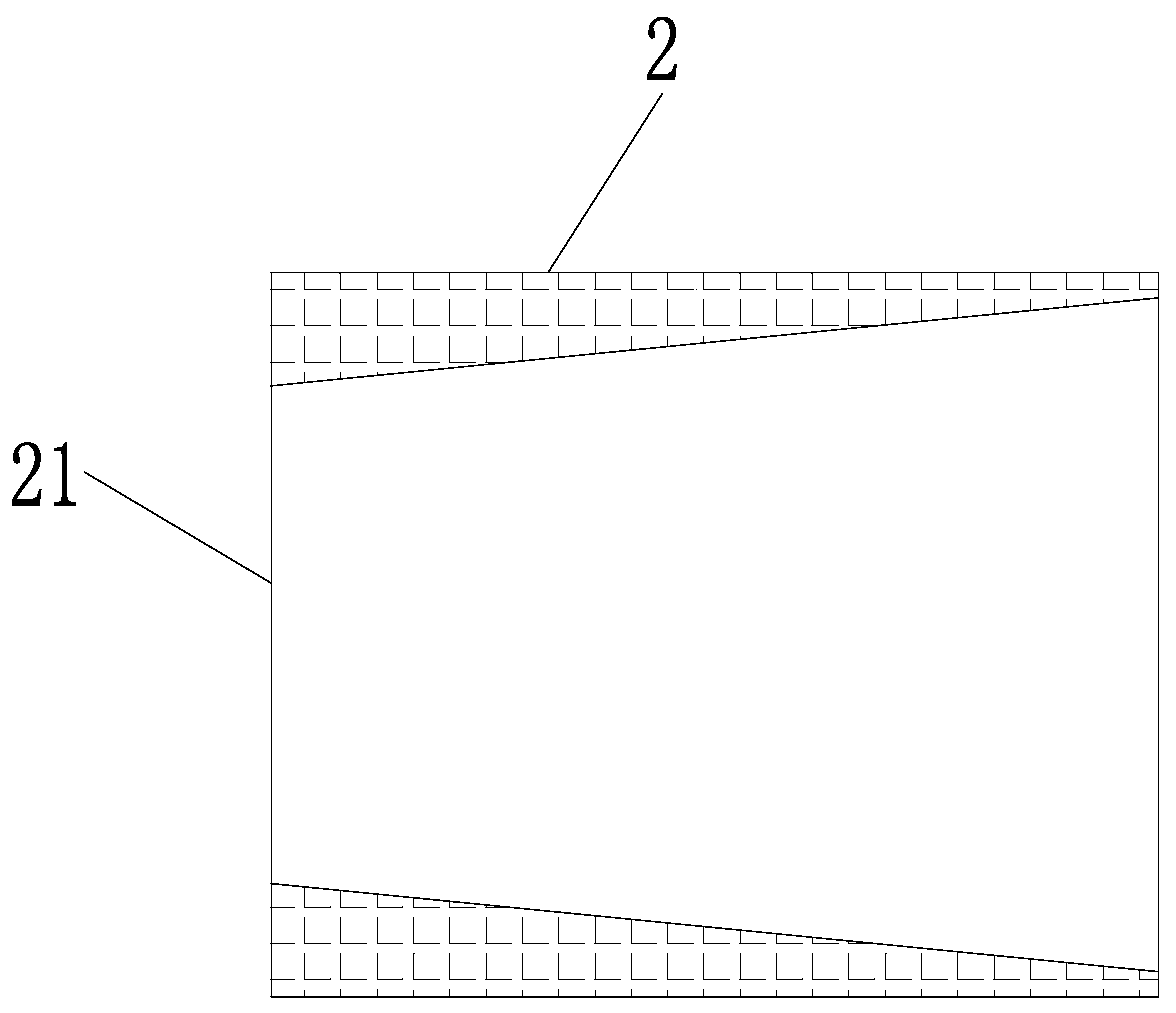

[0068] Such as Figure 6 As shown, the difference from Example 1 is that the packing density of the counter-current rotating packing layer 2 increases toward the axial center gas phase outlet port 21 of the counter-current rotating packing layer 2 along the rotational axis of the counter-current rotating packing layer 2, along the The radial thickness of the counter-current rotating packing layer 2 on the rotating axis of the counter-current rotating packing layer 2 is uniform, while the packing density changes stepwise along the rotating axis of the counter-current rotating packing layer 2. The counter-current rotating packing layer 2 is composed of porous Packing structure, the filler porosity near the axial center gas phase outlet end 21 is getting smaller and smaller, thereby increasing the air intake resistance of the countercurrent rotating packing layer 2 on the axial center gas phase outlet end 21 side in the axial direction, and solving the problem of The axial uneven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com