Metal surface treatment method

A metal surface treatment and metal surface technology, applied in the field of metal surface treatment, can solve the problems of incompleteness, difficulty in taking out, poor surface polishing effect, etc., and achieve the effect of enhancing surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

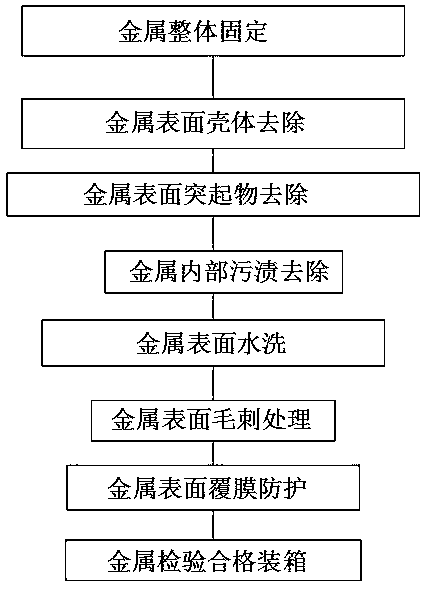

[0023] The present invention provides such figure 1 Shown a kind of metal surface treatment method, specifically comprises the following steps:

[0024] Step 1. Fixing the metal as a whole: First, fix the metal to be processed by the clamping manipulator, then tilt the metal to be processed to an angle of 30° through the clamping manipulator, and then fix a protective shell on the outside of the metal to prevent post-processing. spills of waste;

[0025] Step 2. Metal surface shell removal: After that, the high-frequency vibrator is fixed on the metal surface, and the high-frequency vibrator performs high-frequency vibration to separate the shell and waste that need to be separated from the metal. At the same time, a blower is used to blow off the waste, which is unstable The metal breaks after being vibrated by a high-frequency vibrator, and then the precision of the metal as a whole can be detected to prevent the breakage of the later use. After that, the remaining stains o...

Embodiment 2

[0034] Further, in the above-mentioned embodiment 1, a metal surface treatment method specifically includes the following steps:

[0035] Step 1. Fixing the metal as a whole: First, fix the metal to be processed by the clamping manipulator, then tilt the metal to be processed to an angle of 45° through the clamping manipulator, and then fix a protective shell on the outside of the metal to prevent post-processing. spills of waste;

[0036]Step 2. Metal surface shell removal: After that, the high-frequency vibrator is fixed on the metal surface, and the high-frequency vibrator performs high-frequency vibration to separate the shell and waste that need to be separated from the metal. At the same time, a blower is used to blow off the waste, which is unstable The metal breaks after being vibrated by a high-frequency vibrator, and then the precision of the metal as a whole can be detected to prevent the breakage of the later use. After that, the remaining stains on the surface are...

Embodiment 3

[0045] The present invention provides such figure 1 Shown a kind of metal surface treatment method, specifically comprises the following steps:

[0046] Step 1. Fixing the metal as a whole: First, fix the metal to be processed by the clamping manipulator, then tilt the metal to be processed to an angle of 60° through the clamping manipulator, and then fix a protective shell on the outside of the metal to prevent post-processing. spills of waste;

[0047] Step 2. Metal surface shell removal: After that, the high-frequency vibrator is fixed on the metal surface, and the high-frequency vibrator performs high-frequency vibration to separate the shell and waste that need to be separated from the metal. At the same time, a blower is used to blow off the waste, which is unstable The metal breaks after being vibrated by a high-frequency vibrator, and then the precision of the metal as a whole can be detected to prevent the breakage of the later use. After that, the remaining stains o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com