Focus locking detection system and method of microscope

A detection system and detection method technology, which is applied in the field of microscope focus detection system, can solve problems such as limited size, impossible detection, complex system, etc., and achieve the effect of precise detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

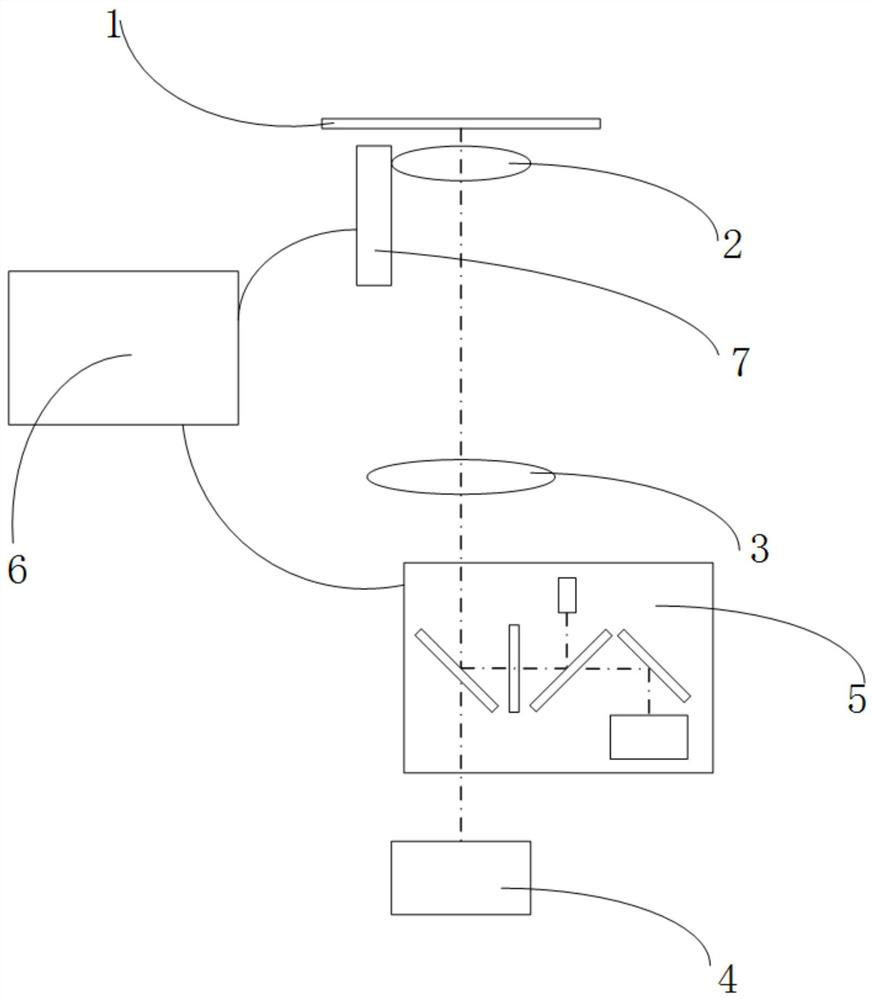

[0050] see Figure 1-3 1. A focus-locking detection system of a microscope, comprising: an objective lens 2, a tube lens 3, a focus-locking detection module 5, a focus-locking controller 6, a Z-axis displacement device 7, and an imaging CCD4; the Z-axis displacement device 7 is arranged on the objective lens 2 The side of the sample; the objective lens 2 is directly below the sample 1, the tube lens 3 is directly below the objective lens 2, the imaging CCD4 is directly below the tube lens 3, and the focus detection module 5 is between the tube lens 3 and the imaging CCD4, The focus detection module 5, the focus controller 6, and the Z-axis shifter 7 are connected in sequence.

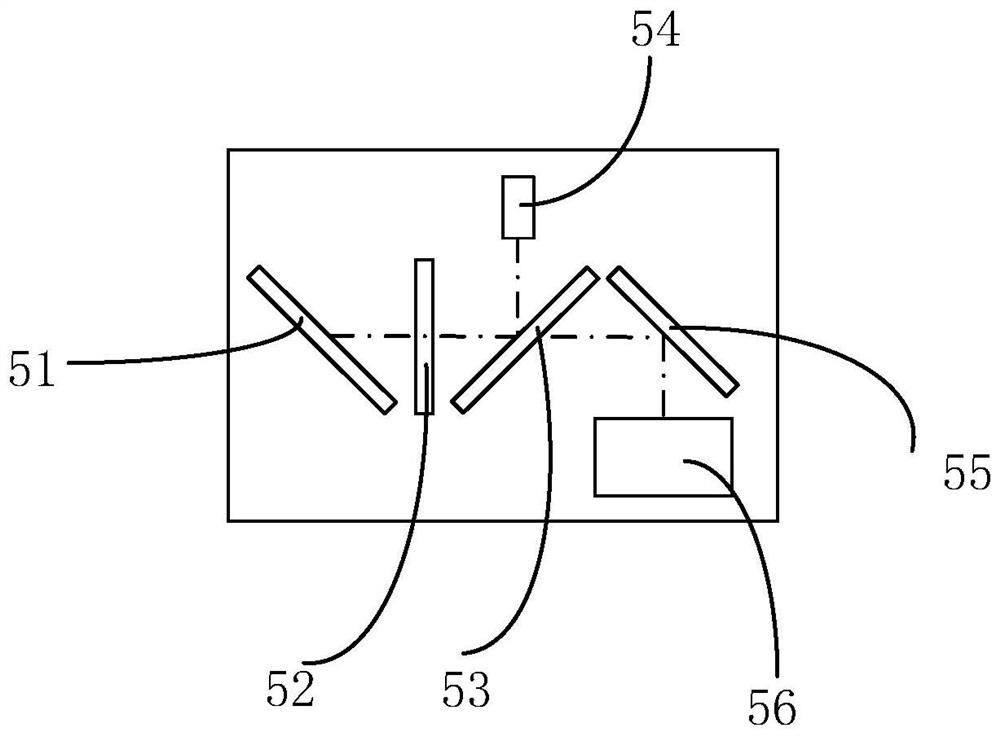

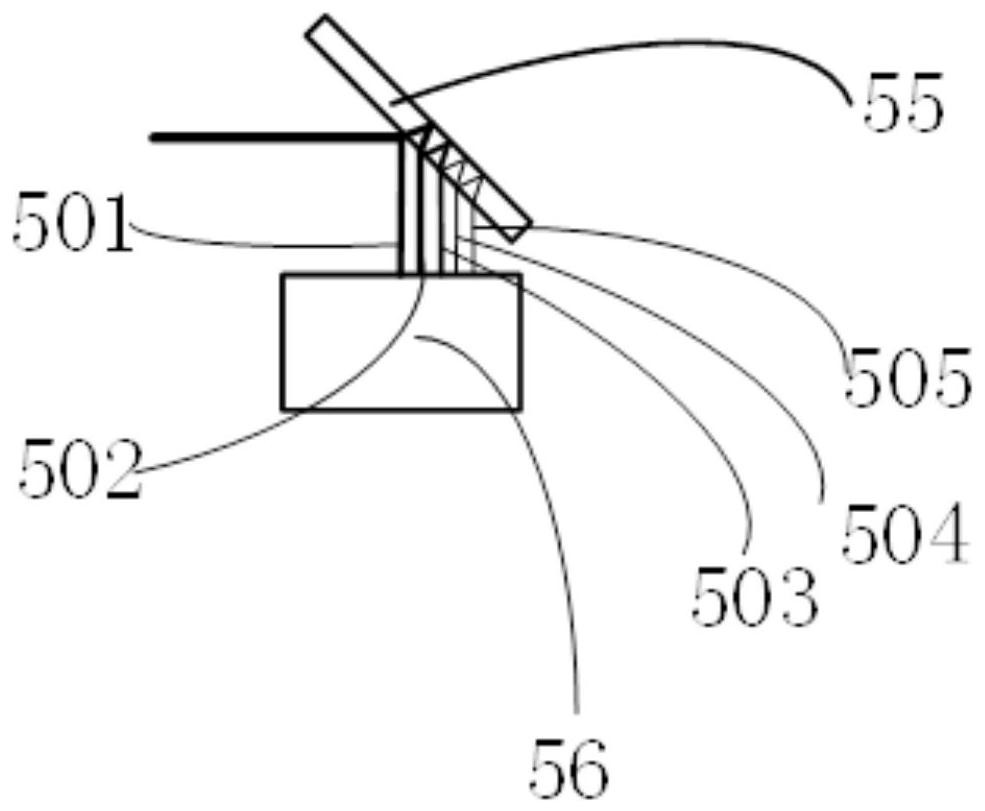

[0051] In this embodiment, the focus detection module 5 includes: a first spectroscopic lens 51, a quarter wave plate 52, a second spectroscopic lens 53, a light source 54, a third spectroscopic lens 55 and a linear detector 56; The mirror 51 is obliquely arranged directly below the tube mirror 3, the ...

Embodiment 2

[0101] see Figure 4 The difference between Embodiment 2 and Embodiment 1 is that the focus detection module 5 further includes: a collimating lens 57; The straight lens 57, the first dichroic mirror 51 and the quarter wave plate 52 are on the same horizontal optical axis. The focus lock detection method also includes: the circularly polarized light passing through the quarter-wave plate enters the collimating lens 57, becomes parallel light after passing through the collimating lens 57, and the parallel light enters the first spectroscopic lens 51; the light reflected by the sample 1 After being reflected by the dichroic mirror, it enters the collimating lens 57 , becomes focused light after passing through the collimating lens 57 , and the focused light enters the first dichroic mirror 51 . Embodiment 2 avoids the loss of light used for imaging by adding a collimating lens 57 .

[0102] In the present invention, the axial magnification is used as the optical magnification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com