Method for removing impurity in the process of air delivery of powdered materials

A technology of airflow transportation and foreign matter, which is applied in the direction of separating solids from solids by airflow, conveyors, chemical instruments and methods, etc., which can solve the problems that cannot be popularized and utilized, the production process is not processed, operation and maintenance are inconvenient, etc. problems, to achieve the effect of ingenious internal structure design and layout, convenient operation and maintenance, and improved quality and reputation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

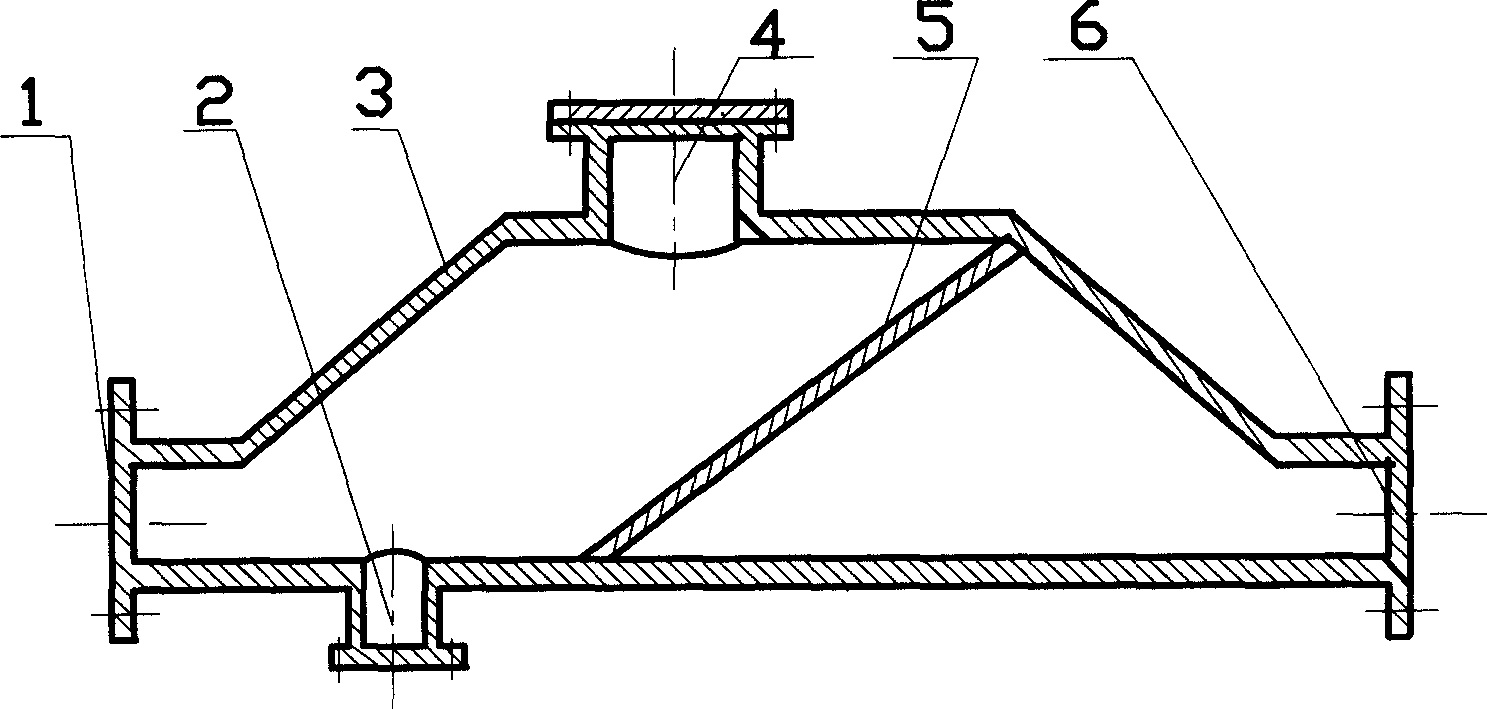

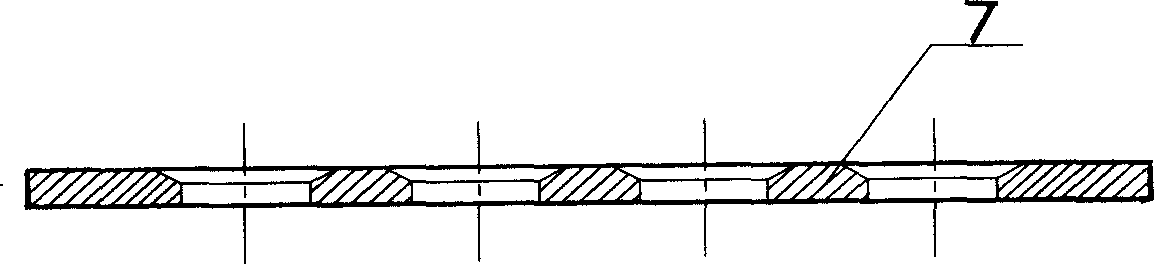

[0018] Foreign matter removal device in PTA production equipment, such as figure 1 As shown, a foreign matter removal device is added to the pipeline from the intermediate storage tank to the finished product storage tank. The foreign matter removal device includes a casing and a sieve plate. The left side of the casing is provided with a feed port, and the right side of the casing is provided with a discharge port. The upper and lower parts are provided with hand holes, the sieve plate is arranged between the upper and lower shells, the sieve plate is provided with cone and cylindrical sieve holes, the opening rate is 30%, and the inclination of the sieve plate is 20 degrees.

Embodiment 2

[0020] It is basically the same as Example 1, except that the opening rate of the sieve plate is 45%, and the inclination of the sieve plate is 60 degrees.

Embodiment 3

[0022] It is basically the same as Example 1, except that the opening rate of the sieve plate is 36% and the inclination of the sieve plate is 40 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com