Preparation method and used reaction system of trimanganese tetraoxide, and uses of used reaction system

A technology of trimanganese tetraoxide and reaction system, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of low dissolved oxygen rate, low production efficiency, low dissolved oxygen amount, etc., and achieve the effect of ensuring the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

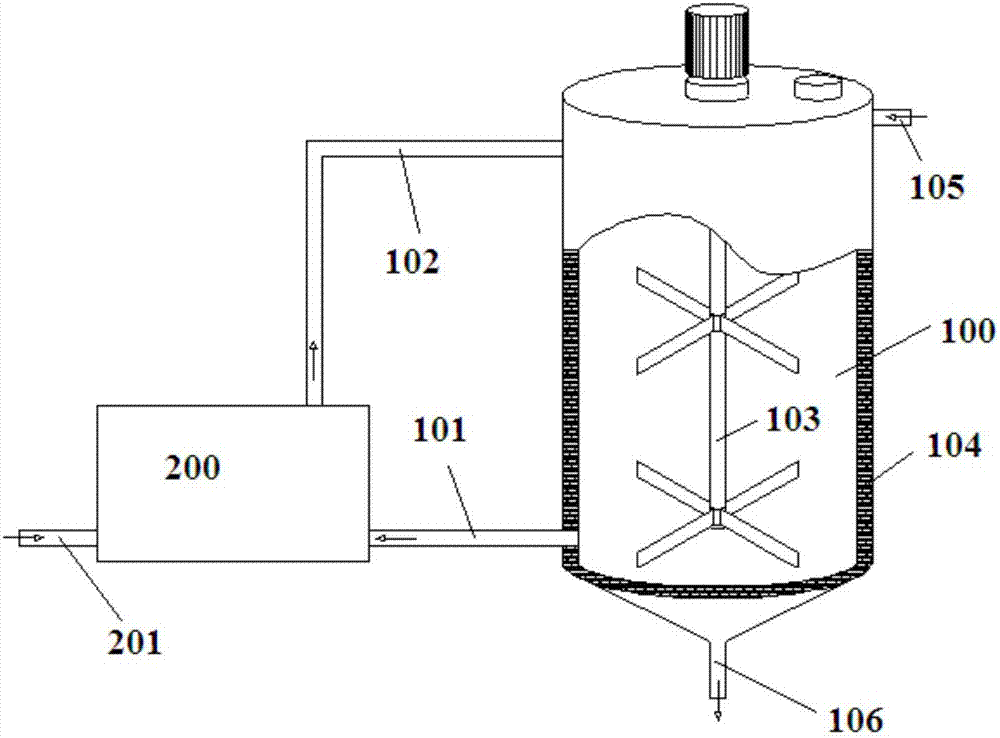

Method used

Image

Examples

Embodiment 1

[0094] Example 1 Weigh 8.8g of manganese hydroxide solid and 500mL of pure water into the normal-pressure reaction kettle, extract 800mL of the reaction liquid mixture in the reaction kettle at one time and pass it into the micro-nano bubble generator, and pass it into the air to obtain air-containing micro-nano Air-liquid mixture with bubbles. The average diameter of the micro-nano bubbles in the liquid-gas mixture is 15.3 μm. In the micro-nano-bubble aqueous solution, the oxygen content in the liquid-gas mixture is 26 mg / L, and the volume ratio of the gaseous oxygen in the micro-nano bubbles to the reaction liquid mixture is 0.16. Then put the liquid-gas mixture into the reaction kettle, react at room temperature and normal pressure for 2.0 hours, and the obtained solid phase is trimanganese tetraoxide.

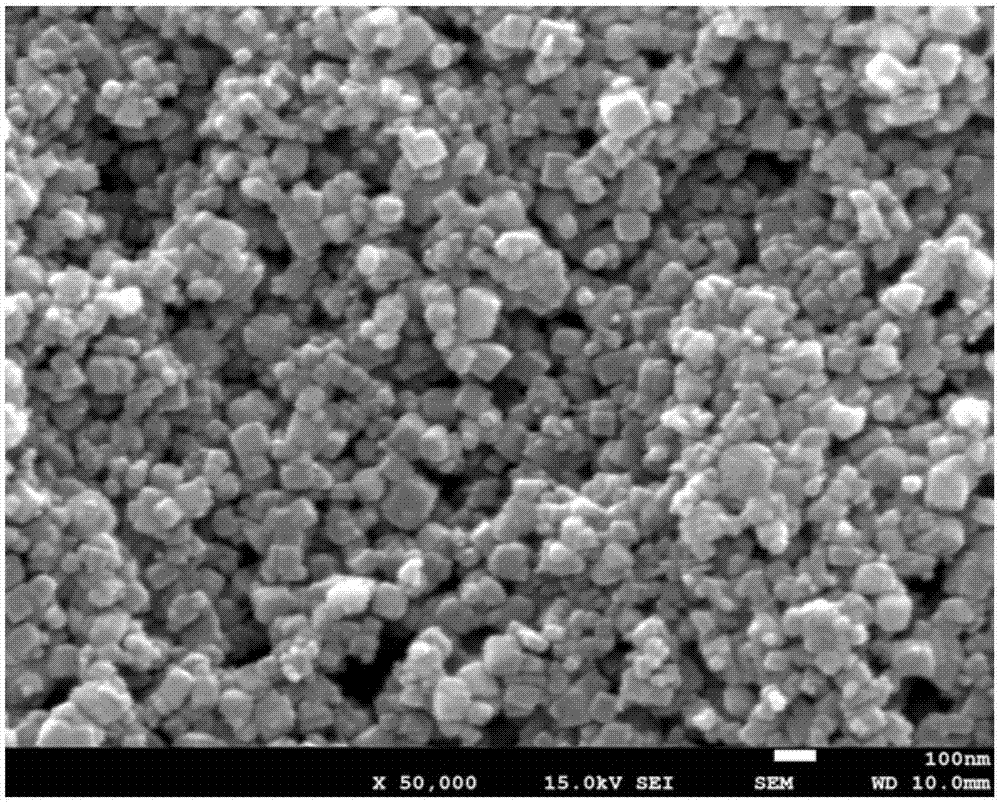

[0095] figure 2 is the particle size and morphology of the crystals of trimanganese tetraoxide prepared in Example 1 of the present invention;

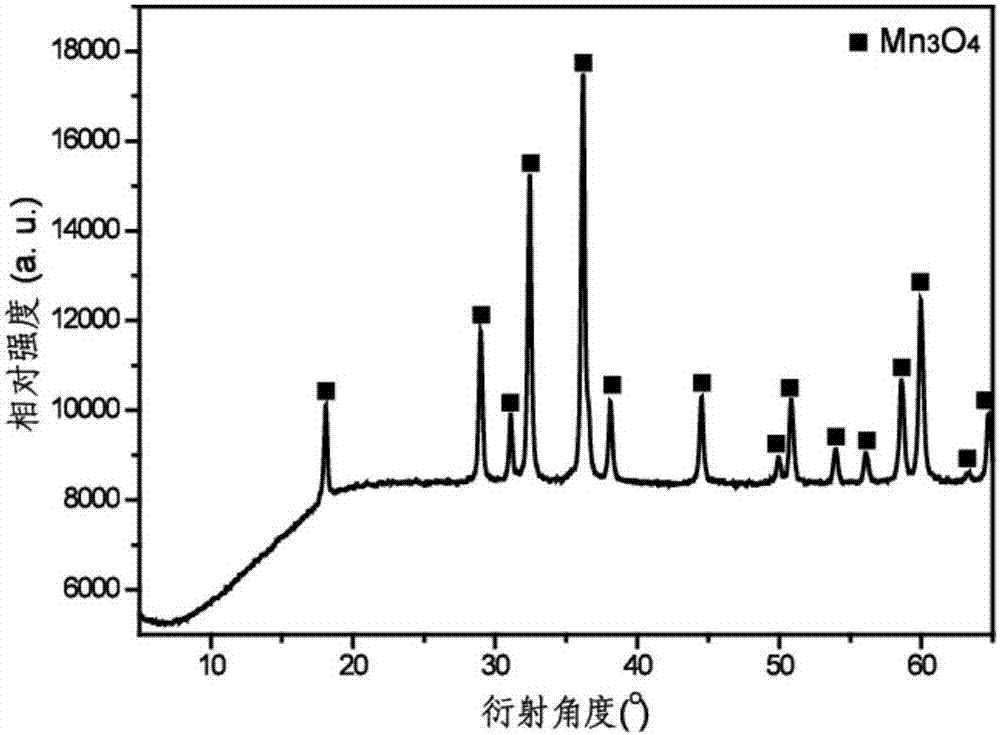

[0096] image 3 is the ...

Embodiment 2

[0097] Example 2 Weighed 70.0 g of manganese monoxide solid and 4000 mL of pure water into the reactor, and injected 10.0 L of liquid-gas mixture of water with oxygen micro-nano bubbles into the reactor at one time. The average diameter of the micro-nano bubbles is 6.2 μm, the oxygen content in the liquid-gas mixture containing the micro-nano bubbles is 58 mg / L, and the volume ratio of the gaseous oxygen in the micro-nano bubbles to the reaction liquid mixture is 0.63. The temperature was raised to 90°C under normal pressure for 0.5h reaction, and the obtained solid phase was trimanganese tetraoxide.

Embodiment 3

[0098] Embodiment 3 Weigh manganese monoxide solid 7.0g and pure water 250mL and add in the autoclave, in the autoclave, continuously pass into the liquid-gas mixture of the water containing the micro-nano bubbles of air and argon, the flow rate of the liquid-gas mixture is 500.0mL / h. Air and argon account for 90.0vol% and 10.0vol% respectively in the gas. The average diameter of the micro-nano bubbles is 0.2μm. The volume ratio of the reaction liquid mixture was 9.12. Raise the temperature from the pressure to 190°C and react for 0.5h, and the obtained solid phase is trimanganese tetraoxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com