Non-manganese element-containing trimanganese tetraoxide complex, preparation method, used reaction system and uses thereof

A technology of manganese tetroxide and compound, applied in the directions of manganese oxide/hydroxide, electrical components, hybrid capacitor electrodes, etc., can solve the problems of slow conversion rate, low dissolved oxygen rate, impurities in the product, etc., and improve the solubility. and the dissolution rate, the effect of ensuring the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

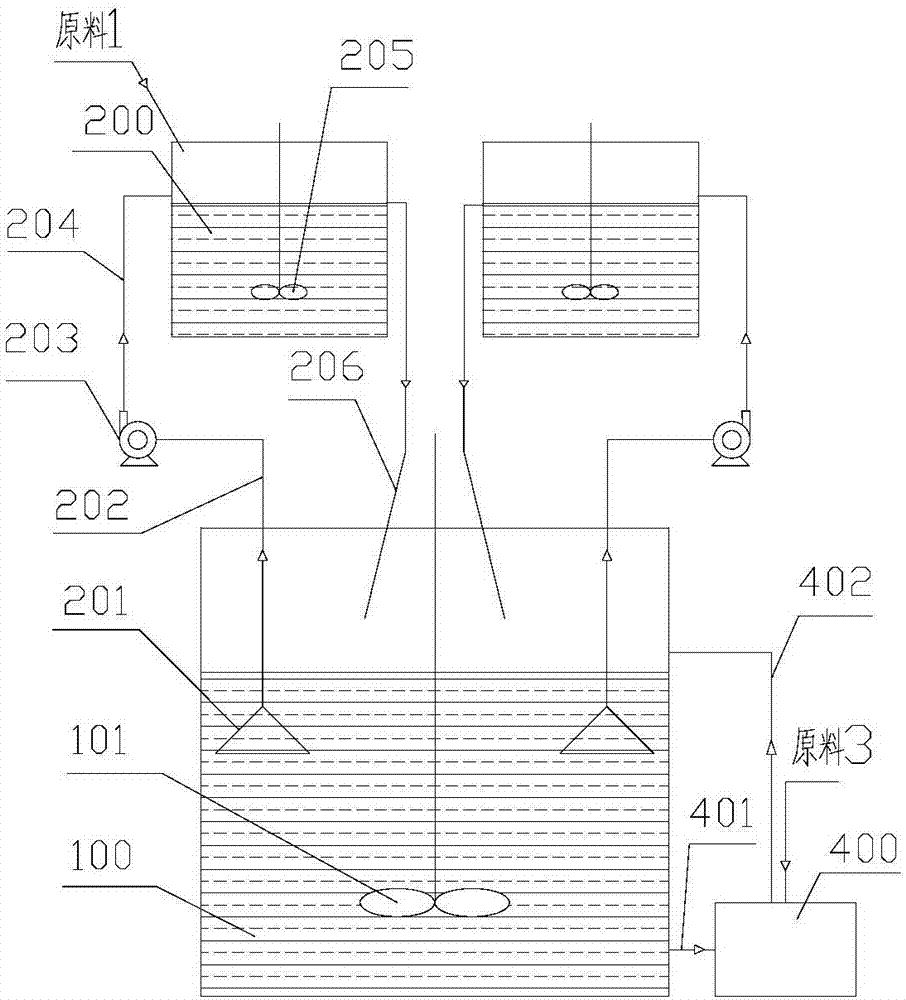

[0110] Example 1 Weigh 90.0 g of the newly prepared manganese hydroxide solid, 2.0 g of the newly prepared magnesium hydroxide colloid, and 1.0 L of purified water and add them to the normal-pressure reactor; extract 0.8 L of the reaction liquid mixture in the reactor at one time and feed it into micro-nano bubbles The generator is fed with air to obtain a liquid-gas mixture containing air micro-nano bubbles. The average diameter of the micro-nano bubbles in the liquid-gas mixture is 15.1 μm, the oxygen content in the liquid-gas mixture is 28 mg / L, and the volume ratio of the gaseous oxygen in the micro-nano bubbles to the reaction liquid mixture is 0.17. Then put the liquid-gas mixture into the reaction kettle, react at room temperature and normal pressure for 2.0 h, and the obtained solid phase is magnesium-containing trimanganese tetraoxide compound. A part of magnesium ions in the composite enters the trimanganese tetraoxide crystal lattice in the form of lattice substitut...

Embodiment 2

[0111] Example 2 Weigh 68.0 g of manganese monoxide solids, 8.0 g of lithium chloride and 4.0 L of pure water into the reactor, and in the reactor, 20.0 L of the liquid-gas mixture of water with micro-nano bubbles of oxygen and carbon dioxide are introduced into the reactor at one time. . Oxygen and carbon dioxide in the gas account for 98.0vol% and 2.0vol% respectively, the average diameter of micro-nano bubbles is 5.8μm, and the content of oxygen in the liquid-gas mixture containing micro-nano bubbles is 56mg / L. The gaseous oxygen in the micro-nano bubbles reacts with The volume ratio of the liquid mixture was 0.62. The temperature was raised to 90°C under normal pressure for 0.5h reaction, and the obtained solid phase was lithium-containing trimanganese tetraoxide complex. The composite is a mixture of trimanganese tetraoxide phase and lithium carbonate phase, both of which have particle sizes less than 100nm.

Embodiment 3

[0112] Example 3 Weigh 70.0 g of manganese monoxide solid, 1.6 g of ferric titanate and 2.4 L of pure water into a high-pressure reactor, and continuously feed a liquid-gas mixture of water containing micro-nano bubbles of air and argon into the reactor , the flow rate of liquid-gas mixture is 5.0L / h. Air and argon account for 90.0vol% and 10.0vol% respectively in the gas. The average diameter of the micro-nano bubbles is 0.2μm. The volume ratio of the reaction liquid mixture was 9.08. Raise the temperature from the pressure to 190°C and react for 0.5h, and the obtained solid phase is a manganese tetraoxide complex containing iron and titanium. The composite is a mixture of trimanganese tetraoxide phase and iron titanate phase, and the particle size reaches 1.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com