Preparation method high-purity high-yield oxysophocarpine

A technology of oxidative sophocarpine and high yield, applied in the direction of organic chemistry and the like, to achieve the effects of high yield, simple preparation process and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

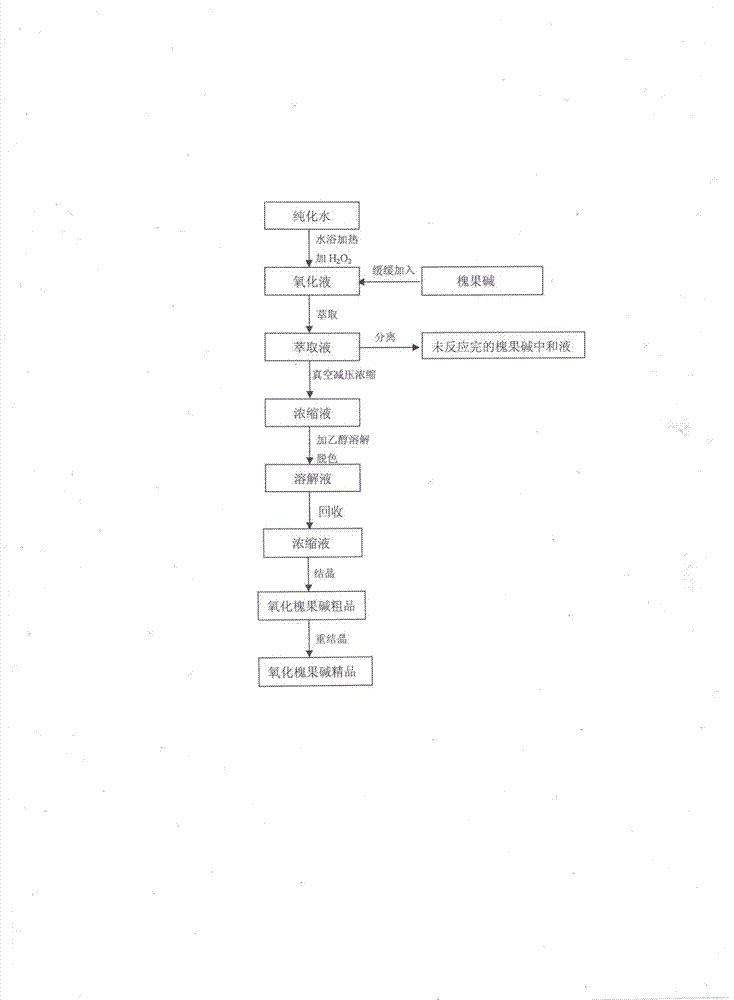

Method used

Image

Examples

Embodiment 1

[0023] (1) Add water to the oxidation tank and raise the temperature of the water bath to about 75°C, measure and add 20kg of hydrogen peroxide, slowly add 40kg of sophocarpine, and dissolve;

[0024] (2) Reduce the temperature to 62°C for 7.5 hours at a constant temperature, and detect that there is no hydrogen peroxide;

[0025] (3) Extract unreacted sophocarpine with toluene until there is basically no sophocarpine in the oxidation solution;

[0026] (4) Concentrate the reaction solution under reduced pressure in vacuo, add ethanol to dissolve, and filter with suction;

[0027] (5) The filtrate is passed through alumina (Al 2 o 3 ) for decolorization, suction filtration, and recovery;

[0028] (6) Stir with acetone, cool and crystallize, and centrifuge to obtain 38.8 kg of crude sophocarpine oxide;

[0029] (7) 37.6kg of fine oxidized sophocarpine was obtained by recrystallization of the crude product of oxidized sophocarpine, and the content was determined to be 99.6%....

Embodiment 2

[0031] (1) Add water to the oxidation tank and raise the temperature of the water bath to about 75°C, measure and add 20kg of hydrogen peroxide, slowly add 40kg of sophocarpine, and dissolve;

[0032] (2) Reduce the temperature to 60°C for 8 hours, and detect the absence of hydrogen peroxide;

[0033] (3) Extract unreacted sophocarpine with ether until there is basically no sophocarpine in the oxidation solution;

[0034] (4) Concentrate the reaction solution under reduced pressure in vacuo, add ethanol to dissolve, and filter with suction;

[0035] (5) The filtrate is decolorized by activated carbon, filtered and recovered;

[0036] (6) Add acetone to stir, cool and crystallize, and centrifuge to obtain 38 kg of crude product of oxysophocarpine;

[0037] (7) 37.1kg of fine oxidized sophocarpine was obtained by recrystallization of the crude product of oxidized sophocarpine, and the content was determined to be 99.1%.

Embodiment 3

[0039] (1) Add water to the oxidation tank and raise the temperature of the water bath to about 75°C, measure and add 20kg of hydrogen peroxide, slowly add 40kg of sophocarpine, and dissolve;

[0040] (2) Reduce the temperature to 58°C for 8.5 hours at a constant temperature, and detect that there is no hydrogen peroxide;

[0041] (3) Extract unreacted sophocarpine with benzene until there is basically no sophocarpine in the oxidation solution;

[0042] (4) Concentrate the reaction solution under reduced pressure in vacuo, add ethanol to dissolve, and filter with suction;

[0043] (5) The filtrate is passed through alumina (Al 2 o 3 ) for decolorization, suction filtration, and recovery;

[0044] (6) Stir with acetone, cool and crystallize, and centrifuge to obtain 38.5 kg of crude product of oxysophocarpine;

[0045] (7) 37.5kg of fine oxidized sophocarpine was obtained by recrystallization of the crude product of oxidized sophocarpine, and the content was determined to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com