Process and device for preparing ferric chloride

A technology of ferric chloride and process, which is applied in the field of waste liquid treatment, can solve the problems of high cost and high risk, and achieve the effects of reducing reaction cost, simple equipment and saving reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

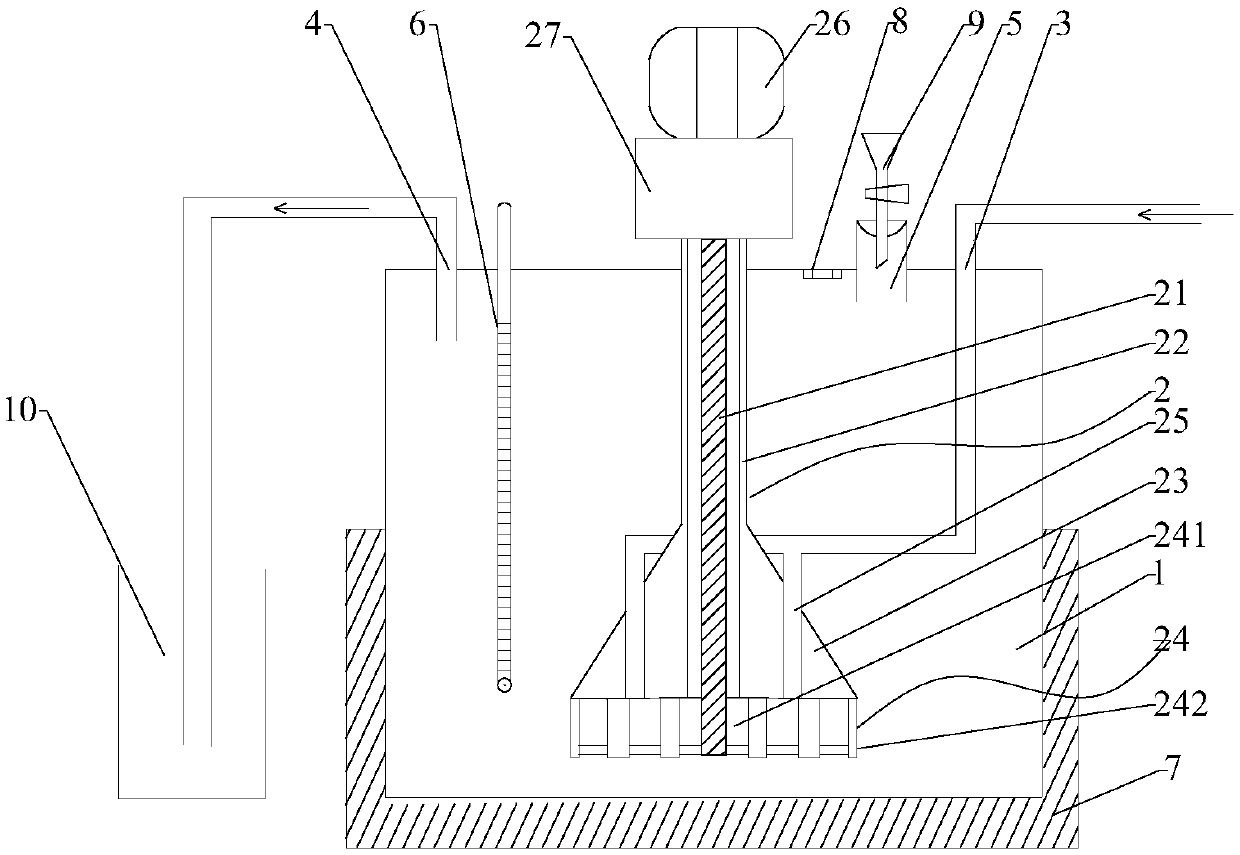

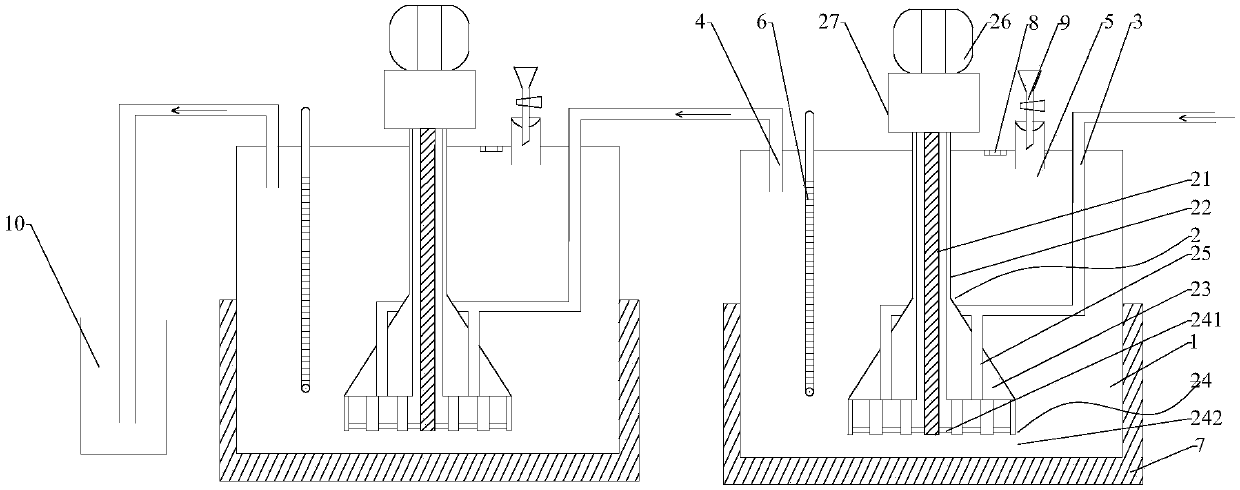

[0046] Such as Figure 1~2 As shown, a kind of device that the present invention proposes to prepare ferric chloride comprises reaction tank, and reaction tank comprises reaction tank body 1, stirring mechanism 2, air inlet 3, air outlet 4, catalyst inlet 5, air inlet 3 and the gas outlet 4 are all arranged on the top of the reaction tank body 1, and the stirring mechanism 2 extends into the reaction tank body 1,

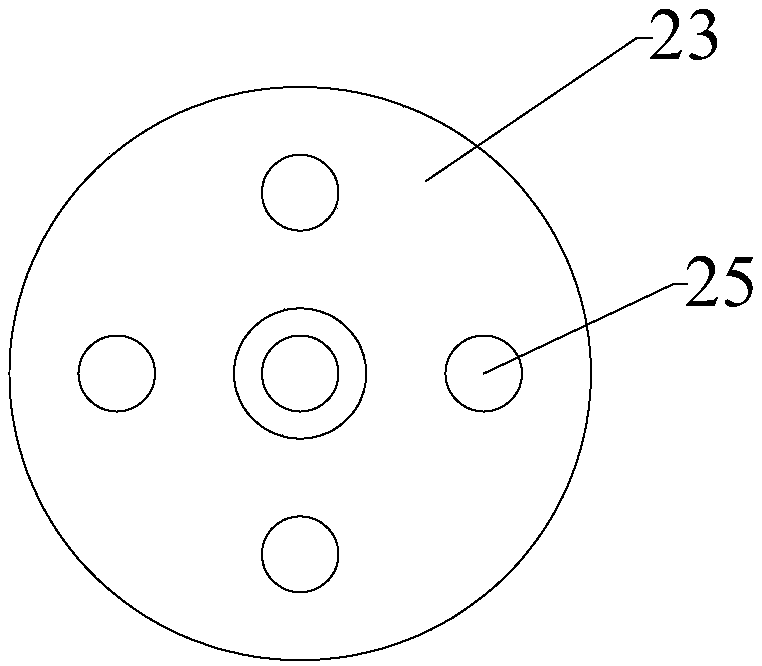

[0047] Stirring mechanism 2 comprises transmission shaft 21, hollow shaft sleeve 22 and impeller 24, and hollow shaft sleeve 22 is sleeved on the transmission shaft 21, and impeller 24 is arranged below hollow shaft sleeve 22, and air inlet 3 is connected with air intake duct, and air intake The pipeline is connected with the impeller 24,

[0048] The impeller 24 includes a moving impeller 241 and a stationary impeller 242 , the moving impeller 241 is arranged in the stationary impeller 242 , and the moving impeller 241 is arranged on the transmission shaft 21 .

...

Embodiment 2

[0059] Adopt the device of embodiment 1 to prepare the method for ferric chloride, may further comprise the steps:

[0060] S1, take 2750mL pickling waste liquid and add 330mL concentrated hydrochloric acid to obtain a mixed solution with a total mass of 3990g, wherein the concentration of ferrous chloride in the pickling waste liquid is 2.62mol / L, and the concentration of hydrogen chloride is 1.17mol / L , the concentration of hydrogen chloride in concentrated hydrochloric acid is 12mol / L;

[0061] S2, add 20g NH to the mixed solution obtained in step S1 4 After the Cl is transferred to the reaction tank body 1, the motor 26 is started, and the air is fed into the air inlet 3 and the temperature is raised to 60° C. at the same time;

[0062] S3. Oxygen is introduced from the air inlet 3, and NaNO is added dropwise through the catalyst inlet 5 2 , it is 1 drop / second with dropping funnel 9 control dropping rate;

[0063] S4. Sampling is taken from the sampling port 8 to detec...

Embodiment 3

[0065] Adopt the device of embodiment 1 to prepare the method for ferric chloride, may further comprise the steps:

[0066] S1, take 2750mL pickling waste liquid and add 330mL concentrated hydrochloric acid to obtain a mixed solution with a total mass of 3990g, wherein the concentration of ferrous chloride in the pickling waste liquid is 2.62mol / L, and the concentration of hydrogen chloride is 1.17mol / L , the concentration of hydrogen chloride in concentrated hydrochloric acid is 12mol / L;

[0067] S2, add 20g MnCl to the mixed solution obtained in step S1 2 Then turn it into the reaction tank body 1, start the motor 26, and feed the air through the air inlet 3 and heat up to 60°C at the same time;

[0068] S3. Oxygen is introduced from the air inlet 3, and NaNO is added dropwise through the catalyst inlet 5 2 , it is 1 drop / second with dropping funnel 9 control dropping rate;

[0069] S4. Sampling is taken from the sampling port 8 to detect the concentration of ferrous ions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com