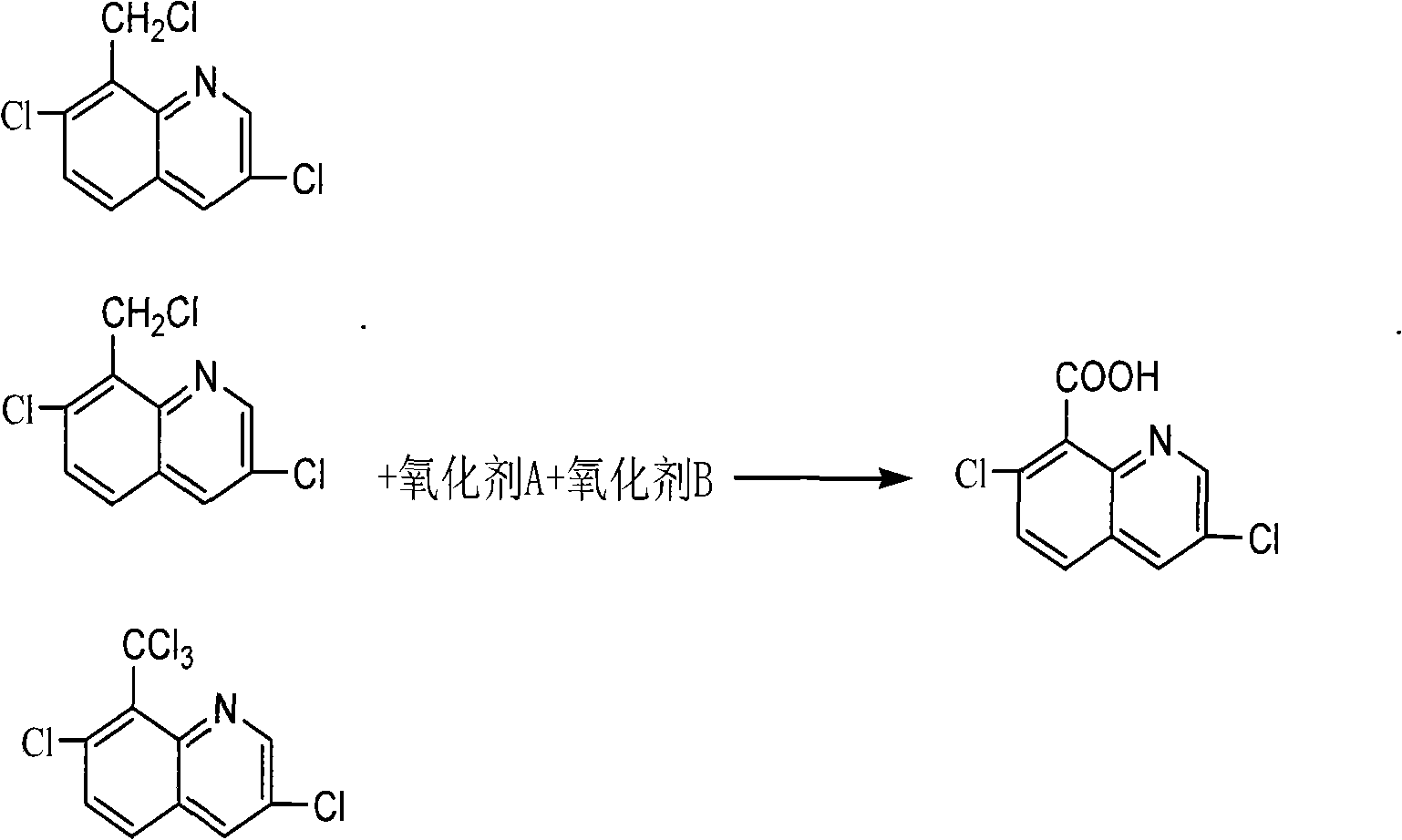

Process for synthesizing quinclorac by oxidizing reaction

A technology of quinclorac and oxidation synthesis, applied in the direction of organic chemistry, etc., can solve the problems of long oxidation process time, limited production capacity, and difficult disposal of waste acid, so as to shorten the oxidation reaction time, improve product quality, and improve equipment utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 500ml four-neck flask, add 120g of water, slowly add 230g of 98% sulfuric acid while stirring, prepare a sulfuric acid solution, add 32g of chloride of 7-chloro-8-methylquinoline, use flat paddle, install 0~ 200°C mercury thermometer, dehydration condenser, stirring at a stirring speed of 300rpm, raising the temperature to 85°C, adding 150g of 15% sodium bromate aqueous solution dropwise, controlling the reaction temperature to 95°C, and the reaction time is 4h. After the reaction is completed, the feed liquid cools down. When the temperature of the oxidation synthesis solution drops to 70°C, add 100g of toluene, stir and extract for 10 minutes, let it stand for stratification, put the lower layer of material liquid into a beaker with water, analyze it, filter it with water, and wash it with water until pH4.0~ 6.0, the wet product of quinclorac was obtained and dried. The toluene mother liquor in the upper layer was recovered by vacuum distillation and used mechani...

Embodiment 2

[0021] Carry out condensation reaction of aniline and glycerol to obtain quinoline, then through the action of initiator, chlorinate through chlorine in an organic solvent, after removing the organic solvent, the chloride of 7-chloro-8-methylquinoline obtained is added Water, add sulfuric acid, form oxidation preparation liquid, the chloride of 7-chloro-8-methylquinoline in this preparation liquid: water: the mass ratio of 98% sulfuric acid is 1: 3: 7.5, get this preparation liquid 300g, drop into In a 500ml four-neck flask, use a flat plate slurry, install a mercury thermometer at 0-200°C, and a dehydration condenser. At a stirring speed of 300rpm, heat up to 100°C, add 32g of 5% hydrogen peroxide dropwise, and control the reaction temperature at 100-115°C. The dropping time is 60min, the dropping is completed, that is, the first oxidation reaction is finished, add 50g of water, and when the material temperature is 110°C, add 120g of 15% sodium bromate aqueous solution dropwis...

Embodiment 3

[0023] In a 500ml four-neck flask, add 120g of water, slowly add 230g of 98% sulfuric acid while stirring, prepare a sulfuric acid solution, add 32g of chloride of 7-chloro-8-methylquinoline, use flat paddle, install 0~ 200°C mercury thermometer, dehydration condenser, at a stirring speed of 300rpm, raise the temperature to 100°C, add 32g of 5% hydrogen peroxide dropwise, control the reaction temperature at 100-115°C, add time for 55min, and complete the dropwise addition, which is the first step After the oxidation reaction is finished, add 50g of water, and when the material temperature is 110°C, add 135g of 15% sodium bromate aqueous solution dropwise, control the reaction temperature at 110-120°C, and add dropwise for 2h 50min during the reaction process, that is, the second oxidation reaction ends. Cool down, when the temperature of the oxidation synthesis solution drops to 50°C, put the feed solution into a beaker with water, water analysis, suction filtration, add water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com