Reverse osmosis concentrated water treatment method

A technology for reverse osmosis concentrated water and a treatment method, which is applied in the field of comprehensive treatment of industrial wastewater, can solve the problems of increasing the cost of wastewater treatment and prolonging the reaction time of ozone oxidation, and achieves the advantages of enhancing the effect of the oxidation reaction, reducing the treatment cost and reducing the oxidation reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

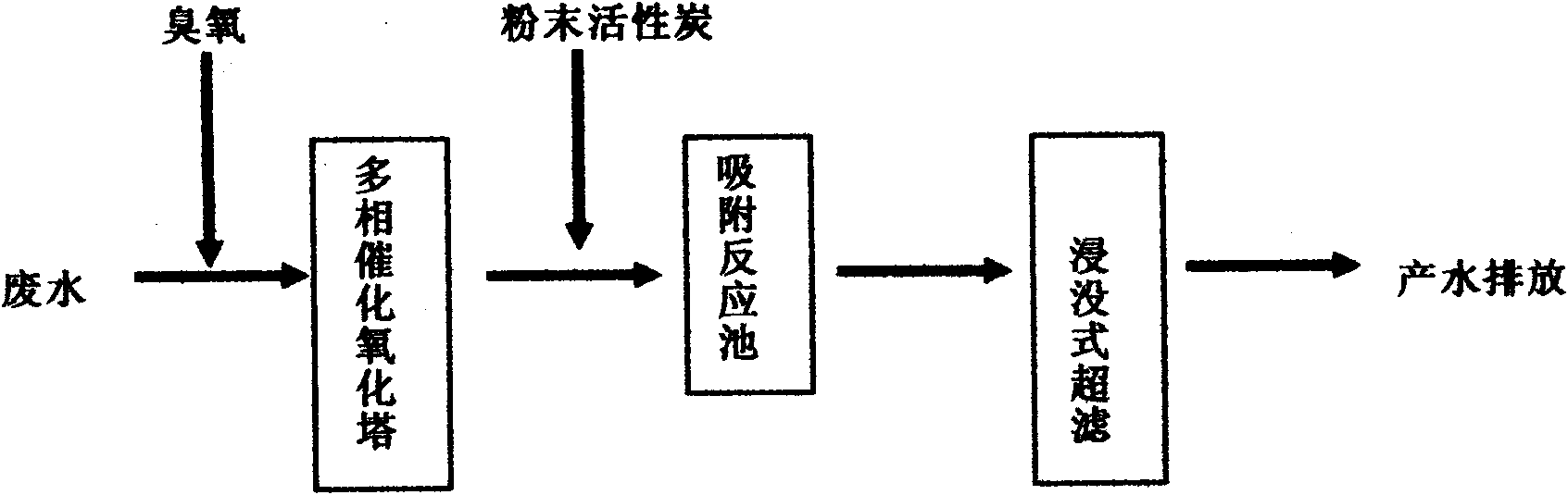

Method used

Image

Examples

Embodiment 1

[0031] The reverse osmosis concentrated water of a biochemical standard wastewater reuse unit in an oil refinery, the wastewater quality characteristics are: COD 128mg / L, pH8.5, conductivity 8020μS / cm, Ca 2+ 107mg / L, turbidity 2.5NTU, BOD 5 0mg / L. The waste water is treated as follows:

[0032] Step 1: The wastewater is pumped into the heterogeneous catalytic oxidation tower, and the tower is filled with a loaded catalyst KH-SC-B [produced by Pingxiang Kehuan Environmental Engineering Co., Ltd., the catalyst composition is (Wt%): O 55.50%, Al 9.25%, Si 18.65%, K 2.22%, Ca 0.85%, Ti0.58%, Fe 8.13%, Cu 4.82%]. The amount of catalyst is half the height of the tower. The operating conditions are: the oxidation time is 30 minutes, and the ozone concentration in the wastewater is 11mg / L. Under these operating conditions, the COD of the product water is 68mg / L, and the turbidity is 2.5NTU;

[0033] Step 2: Catalytic oxidation effluent enters the adsorption reaction pool, and coa...

Embodiment 2

[0036] Reverse osmosis concentrated water from a biochemical standard wastewater reuse unit in an oil refinery, the wastewater quality is characterized by COD 85mg / L, pH 8.21, conductivity 4130μS / cm, Ca 2+ 390mg / L, turbidity 2.0NTU, BOD 5 0mg / L. The waste water is treated as follows:

[0037] Step 1: First, the wastewater enters the catalytic oxidation tower, and the tower is filled with a loaded catalyst KH-SC-B [produced by Pingxiang Kehuan Environmental Engineering Co., Ltd., the catalyst composition is (Wt%): O 55.50%, Al9.25%, Si 18.65%, K 2.22%, Ca 0.85%, Ti0.58%, Fe8.13%, Cu 4.82%]. The amount of catalyst is half the height of the tower. The operating conditions are: the oxidation time is 40 minutes, and the ozone concentration in the wastewater is 10mg / L. Under these operating conditions, the COD of the produced water is 65mg / L, and the turbidity is 2.0NTU;

[0038] Step 2: Catalytic oxidation effluent enters the adsorption reaction pool, and coal-based powdered a...

Embodiment 3

[0041] The secondary reverse osmosis concentrated water of a biochemical standard wastewater reuse unit in an oil refinery, the wastewater quality characteristics are COD111mg / L, pH8.03, conductivity 6020μS / cm, Ca 2+ 646mg / L, turbidity 2.0NTU, BOD 5 0mg / L. The waste water is treated as follows:

[0042] Step 1: First, the wastewater enters the catalytic oxidation tower, and the tower is filled with a loaded catalyst KH-SC-B [produced by Pingxiang Kehuan Environmental Engineering Co., Ltd., the catalyst composition is (Wt%): O 55.50%, Al9.25%, Si 18.65%, K 2.22%, Ca 0.85%, Ti0.58%, Fe8.13%, Cu 4.82%]. The amount of catalyst is half the height of the tower. The operating conditions are: the oxidation time is 50 minutes, and the ozone concentration in the wastewater is 13mg / L. Under these operating conditions, the COD of the produced water is 65mg / L, and the turbidity is 2.5NTU;

[0043] Step 2: Catalytic oxidation effluent enters the adsorption reaction pool, and coal-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com