Method for preparing high-purity high-yield oxysophoridine

A high-yield technology of oxidative sophoridine, applied in the direction of organic chemistry and the like, can solve the problems of low product yield and the like, and achieve the effects of high product purity, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

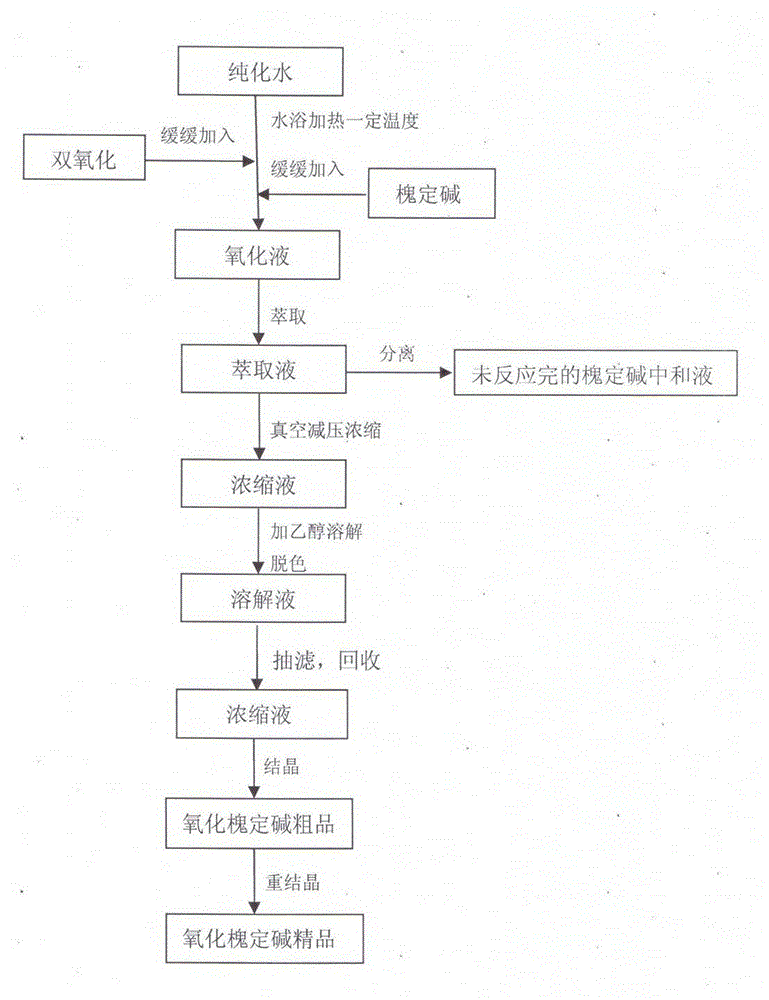

Image

Examples

Embodiment 1

[0024] Add a certain amount of purified water into the oxidation tank, raise the temperature of the water bath to about 75°C, measure and add 20kg of hydrogen peroxide and stir to make it evenly mixed, then slowly add 40kg of sophoridine and stir to dissolve it, then lower the temperature to 58°C and react at a constant temperature for 7.5 hour, after detecting that there is no hydrogen peroxide in the reaction solution, extract the unreacted sophoridine with toluene until there is no sophoridine in the oxidizing solution, then concentrate under reduced pressure in vacuum, then dissolve with ethanol, and the solution is passed through alumina (Al 2 o 3 ) decolorization, suction filtration, recovery, stirring with acetone, cooling and crystallization, centrifugation to obtain 38 kg of crude product of sophodine oxide, and finally recrystallization to obtain 37.1 kg of refined product of sophodine oxide, with a content of 99.1%.

[0025]

Embodiment 2

[0027] Add a certain amount of purified water into the oxidation tank, raise the temperature of the water bath to about 75°C, measure and add 20kg of hydrogen peroxide and stir to make it evenly mixed, then slowly add 40kg of sophoridine and stir to dissolve it, then lower the temperature to 58°C for constant temperature reaction 8 hour, after detecting that there is no hydrogen peroxide in the reaction solution, extract the unreacted sophoridine with petroleum ether until there is no sophoridine in the oxidizing solution, then concentrate under reduced pressure in vacuum, then dissolve with ethanol, and the solution is passed through alumina (Al 2 o 3 ) decolorization, suction filtration, recovery, stirring with acetone, cooling and crystallization, centrifugation to obtain 38.2 kg of crude product of sophodine oxide, and finally recrystallization to obtain 37.4 kg of fine product of sophodine oxide, with a content of 99.4%.

Embodiment 3

[0029] Add a certain amount of purified water into the oxidation tank, raise the temperature of the water bath to about 75°C, measure and add 20kg of hydrogen peroxide and stir to make it evenly mixed, then slowly add 40kg of sophoridine and stir to dissolve it, then lower the temperature to 60°C for constant temperature reaction 7 hours, after detecting that there is no hydrogen peroxide in the reaction solution, extract the unreacted sophoridine with petroleum ether until there is no sophoridine in the oxidized solution, then concentrate under reduced pressure in vacuo, add ethanol to dissolve, the solution is decolorized by activated carbon, and suction filtered. Recover, add acetone to stir, cool and crystallize, and centrifuge to obtain 38 kg of crude sophodine oxide, and finally recrystallize to obtain 36.8 kg of refined sophodine oxide, with a content of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com