Method for producing iron oxide desulphurizing agent in normal temperature

An iron oxide system and production method technology, applied in chemical instruments and methods, separation methods, chemical industry and other directions, can solve the problems of decreased desulfurization agent activity and poor desulfurization effect, and achieves enhanced mixing effect, reduced emissions, and shortened oxidation The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A production method of normal temperature iron oxide series desulfurizer, it comprises the steps:

[0059] 1) The selection of raw materials: by mass percentage: ferrous sulfate heptahydrate (FeSO4 ·7H 2 (2) 10%, calcium carbonate 80%, metamanganic acid 10% choose ferrous sulfate heptahydrate, calcium carbonate and metamanganic acid, for subsequent use;

[0060] 2) Mixing: Mix calcium carbonate and metamanganic acid in a premixer for 20 minutes, drop into ferrous sulfate heptahydrate and continue mixing, and spray water in 5 minutes at the same time, the addition of water is ferrous sulfate heptahydrate, calcium carbonate and 2% of the quality of metamanganic acid to obtain mixture A;

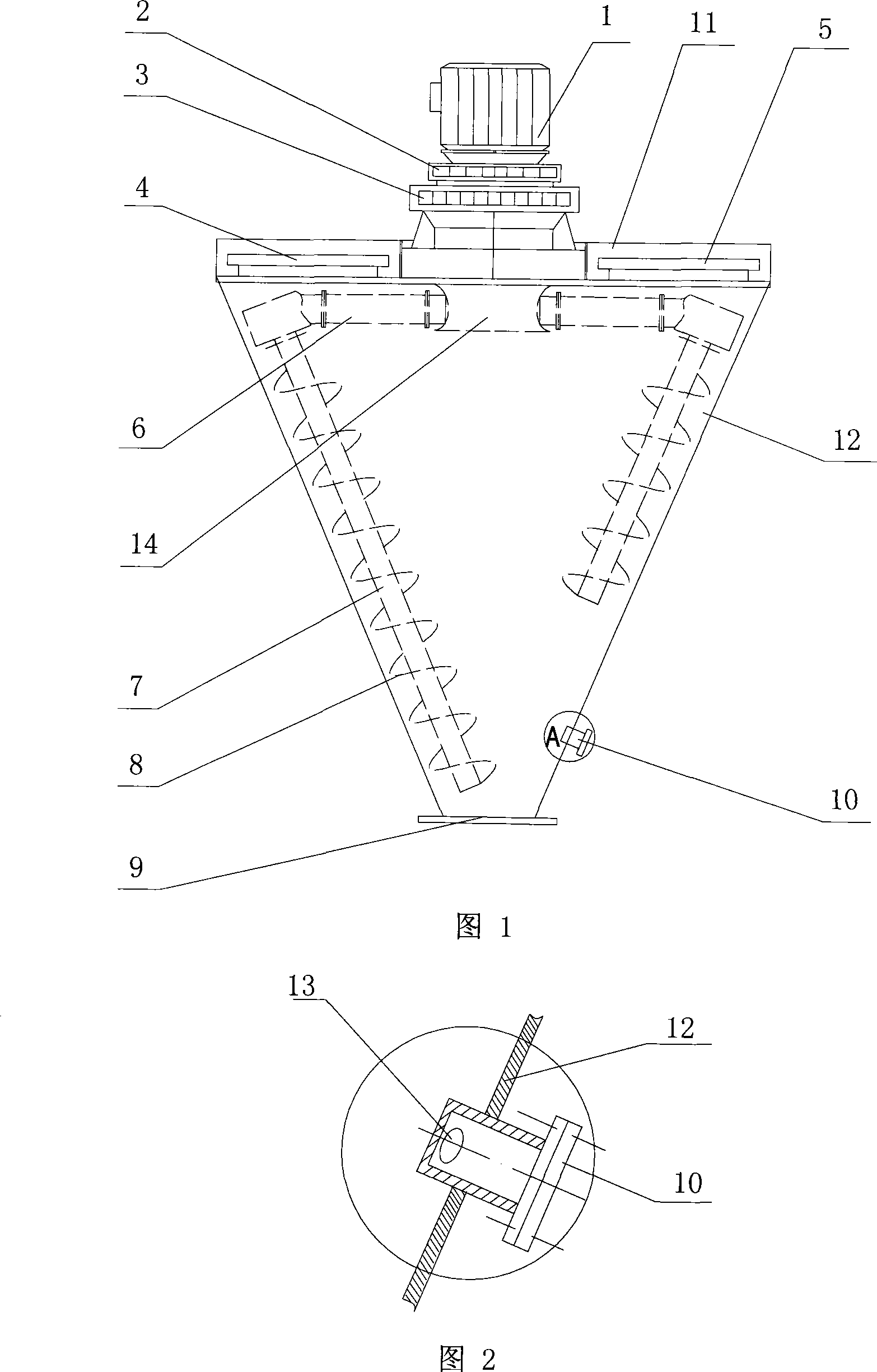

[0061] 3) Solid-phase reaction: Add the mixture A from the solid material inlet of the solid-phase reactor into the conical barrel of the solid-phase reactor, react under the action of stirring and sufficient oxygen, and control the reaction time at 5 minutes to obtain mix B;

[0062]...

Embodiment 2

[0065] A production method of normal temperature iron oxide series desulfurizer, it comprises the steps:

[0066] 1) The selection of raw materials: by mass percentage: ferrous sulfate heptahydrate (FeSO 4 ·7H 2 (2) 50%, calcium carbonate 45%, metamanganic acid 5% choose ferrous sulfate heptahydrate, calcium carbonate and metamanganic acid, for subsequent use;

[0067] 2) Mixing: Mix calcium carbonate and metamanganic acid in the premixer for 25 minutes, drop into ferrous sulfate heptahydrate and continue mixing, and spray water into it in 15 minutes at the same time, the addition of water is ferrous sulfate heptahydrate, calcium carbonate and 5% of the quality of metamanganic acid, to get the mixture A;

[0068] 3) solid-phase reaction: the mixture A is added into the conical cylinder body of the solid-phase reactor from the solid material inlet of the solid-phase reactor, reacted under the action of stirring and sufficient oxygen, and the reaction time is controlled at 50 ...

Embodiment 3

[0072] A production method of normal temperature iron oxide series desulfurizer, it comprises the steps:

[0073] 1) The selection of raw materials: by mass percentage: ferrous sulfate heptahydrate (FeSO 4 ·7H 2 (2) 85%, calcium carbonate 5%, metamanganic acid 10% choose ferrous sulfate heptahydrate, calcium carbonate and metamanganic acid, for subsequent use;

[0074] 2) Mixing: Mix calcium carbonate and metamanganic acid in the premixer for 30 minutes, drop into ferrous sulfate heptahydrate and continue mixing, and spray water into it in 20 minutes at the same time, the addition of water is ferrous sulfate heptahydrate, calcium carbonate and 8% of the quality of metamanganic acid to obtain mixture A;

[0075] 3) Solid-phase reaction: Add the mixture A from the solid material inlet of the solid-phase reactor into the conical barrel of the solid-phase reactor, react under stirring and sufficient oxygen, and the reaction time is controlled at 1000min to obtain mix B;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com