A kind of high-strength iron oxyhydroxide desulfurizer for desulfurization at room temperature and preparation method thereof

An iron oxyhydroxide and desulfurizer technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reduced desulfurization effect of desulfurizers, reduced pore capacity of desulfurizers, weak binding force between raw materials, etc. The raw material mixture is fine, not easy to absorb water, and the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

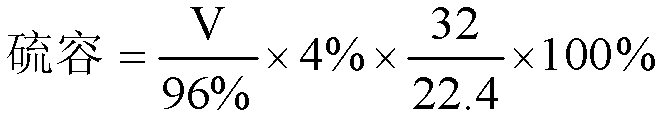

[0031] Put 500g of α-FeOOH and 10g of squash gum into a mixer and grind for 10 minutes, then add 10g of acetic acid and 200g of water to the above material, continue to mix and grind for 10 minutes to obtain a mixture, knead the mixture well and evenly Put it into a screw extruder and extrude it into a strip shaped product of Φ4×2-10mm, and dry the above-mentioned formed product at -5°C for 24 hours to obtain a high-strength iron oxyhydroxide desulfurizer for desulfurization at room temperature. After testing The sulfur capacity of the desulfurizer is 37.6%, and the radial crush resistance is 87N / cm.

Embodiment 2

[0033] Put 950g of β-FeOOH and 400g of guar gum into the mixer and grind for 45 minutes, then add 400g of nitric acid and 400g of water to the above material, continue to mix and grind for 60 minutes to obtain a mixture, and knead the mixture well Put it into a screw extruder and extrude it into a strip-shaped product of Φ4×2-10mm, dry the above-mentioned formed product at 120°C for 3 hours, and obtain a high-strength iron oxyhydroxide desulfurizer for desulfurization at room temperature. After testing, the The sulfur capacity of the desulfurizer is 34.7%, and the radial crush resistance is 120N / cm.

Embodiment 3

[0035] 700g of γ-FeOOH and 200g of carboxymethyl cellulose were put into a mixer and mixed for 30 minutes, then added 150g of hydrochloric acid and 350g of water to the above material, and continued to mix for 40 minutes to obtain a mixture, and the mixture was fully After kneading evenly, put it into a screw extruder to extrude into a strip-shaped product of Φ4×2-10mm, and dry the above-mentioned formed product at 100°C for 10 hours to obtain a high-strength iron oxyhydroxide desulfurizer for desulfurization at room temperature. The sulfur capacity of the desulfurizer was tested to be 33.7%, and the radial crush resistance was 98N / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com