Effluent treatment technology and system based on combination of super magnetic separation and microwave energy technology

A wastewater treatment and magnetic separation technology, applied in the direction of neutralization water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of poor removal efficiency of heavy metals, inability to remove cyanide, insufficient separation, etc. Achieve the effect of reducing oxidation reaction time, reducing precipitation residence time, and facilitating subsequent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

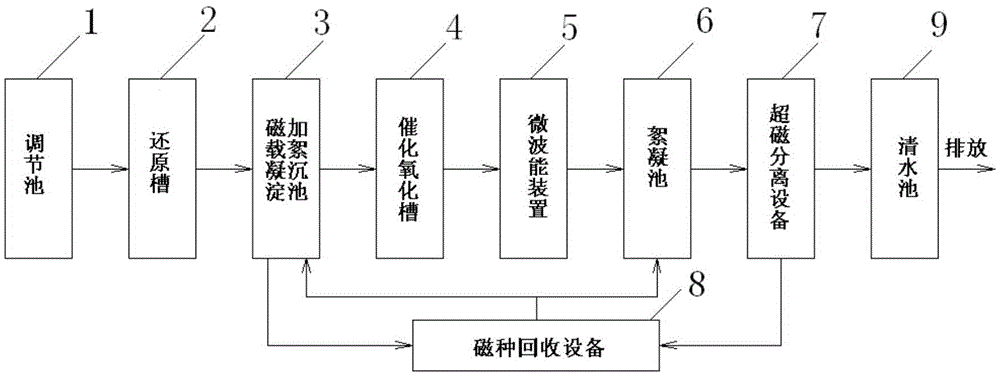

Image

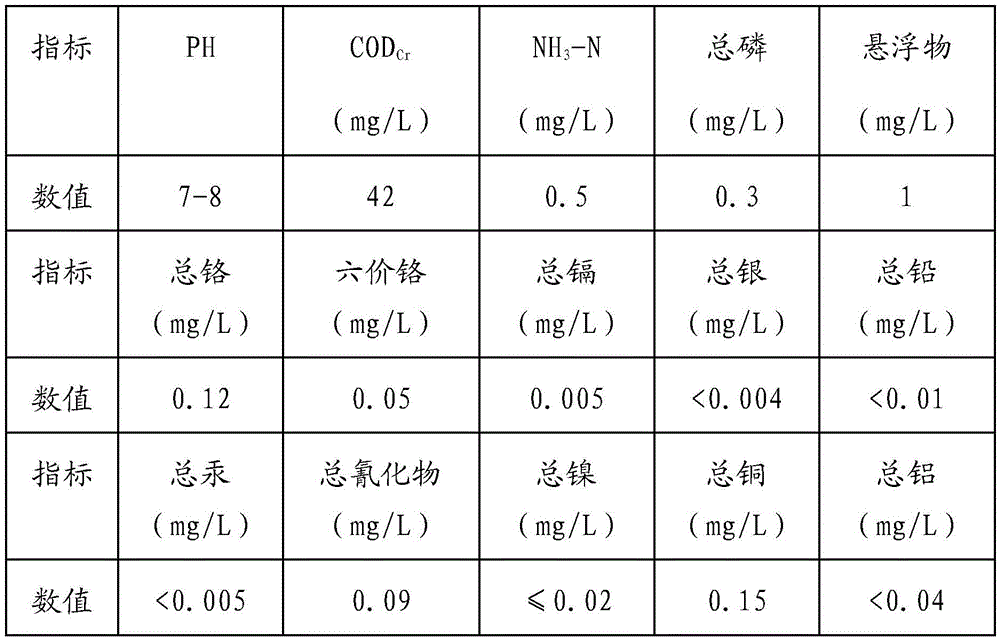

Examples

Embodiment 1

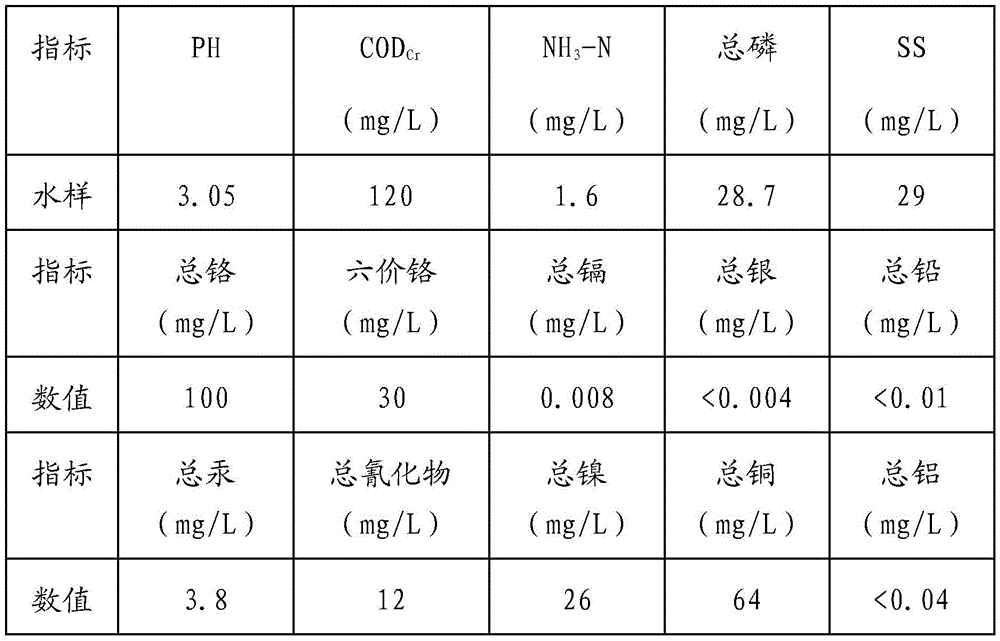

[0035] A battery factory in Ningbo, Zhejiang, produces 500 tons of wastewater per day, and the indicators of influent water quality are shown in Table 1:

[0036] Table 1

[0037]

[0038] The treatment process is as follows:

[0039]S101. The wastewater generated by each unit of the electroplating production line is collected in a centralized manner and sent to the regulating pool for unified treatment.

[0040] S102. Add ferrous sulfate to the waste water as a reducing agent, and adjust the ORP to 150-250. The amount of the reducing agent added is 0.15% of the waste water by mass percentage, and the reaction time is 15 minutes to obtain the mixture A1.

[0041] Ferrous sulfate reacts as a reducing agent, and the reaction formula is:

[0042] 3Fe 2+ +Cr 6+ →3Fe 3+ +Cr 3+

[0043] S103. After adding nano-magnetic seed powder to the mixed solution A1, adjust the pH value to 7-8, add polyaluminum chloride as a flocculant and polyacrylamide as a coagulant, and carry out...

Embodiment 2

[0060] In a battery factory in Ningbo, Zhejiang Province, the production wastewater is 500 tons / day, and the indicators of influent water quality are shown in Table 1 in Example 1:

[0061] The treatment process is as follows:

[0062] S201. The wastewater generated by each unit of the electroplating production line is collected in a centralized manner and sent to the regulating pool for unified treatment.

[0063] S202. Add sodium metabisulfite as a reducing agent to the waste water, and adjust the ORP to 150-250. The amount of the reducing agent added is 0.10% of the waste water by mass percentage, and the mixture A2 is obtained after a reaction time of 10 minutes.

[0064] Sodium metabisulfite reacts as a reducing agent, and the reaction formula is:

[0065] S 2 o 5 2- +H 2 O→2HSO 3 -

[0066] 2HSO 3 - →2SO 3 2- +2H +

[0067] 6SO 3 2- +4Cr 6+ +6OH - →6SO 4 2- +4Cr 3+ +3H 2 o

[0068] S203. After adding the nano-magnetic seed powder to the mixed solut...

Embodiment 3

[0080] In a battery factory in Ningbo, Zhejiang Province, the production wastewater is 500 tons / day, and the indicators of influent water quality are shown in Table 1 in Example 1:

[0081] The treatment process is as follows:

[0082] S301. The wastewater generated by each unit of the electroplating production line is collected in a centralized manner and sent to the regulating pool for unified treatment.

[0083] S302. Add a mixture of sodium metabisulfite and ferrous sulfate to the wastewater as a reducing agent, the mass ratio of the two is 1:1, and adjust the ORP to 150-250. The amount of the reducing agent added is 0.125% of the wastewater by mass percentage , after a reaction time of 30 minutes, mixture A3 was obtained.

[0084] S303. After adding nano-magnetic seed powder to the mixed solution A3, adjust the pH value to 7-8, add ferric chloride as a flocculant and polyamine salt as a coagulant, and then carry out flocculation and sedimentation. The reaction time is 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com