Oxidized wax and preparation method thereof

A technology of wax oxidation and catalytic oxidation, which is applied in petrochemical modification, etc., can solve the problems of poor selectivity of target products, inability to realize directional oxidation, and long reaction time, so as to facilitate industrial production design, shorten oxidation reaction time, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The first aspect of the present invention provides a method for preparing oxidized wax, the method comprising: in the presence of a catalyst and an auxiliary agent, performing a catalytic oxidation reaction of molten Fischer-Tropsch wax with an oxygen-containing gas to obtain oxidized wax;

[0025] Wherein, the catalyst is an iron-based catalyst and / or a cobalt-based catalyst.

[0026] The inventors of the present invention have found that manganese-based catalysts are mainly used for the controllable shallow catalytic oxidation modification of existing waxes, which have low activity and poor selectivity of target products, and the obtained oxidized wax products have an ester-acid ratio of about 1:1, and the catalyst precipitates and deposits at the bottom of the reactor and cannot fully participate in the reaction; the catalyst-free oxidation modification of the existing wax cannot control the product distribution, and cannot achieve directional oxidation, and the slow ...

Embodiment approach

[0045] According to a particularly preferred embodiment of the present invention, a method for preparing oxidized wax, the method comprises: after heating and melting the Fischer-Tropsch wax, adding a catalyst, an auxiliary agent and an oxygen-containing gas for catalytic oxidation to obtain oxidized wax;

[0046] Wherein, the catalyst is iron stearate, the auxiliary agent is glacial acetic acid, and the oxygen content in the oxygen-containing gas is 21-50v%.

[0047] The second aspect of the present invention provides an oxidized wax prepared by the method provided in the first aspect.

[0048] In the present invention, under no special circumstances, the acid value represents the number of milligrams of potassium hydroxide required to neutralize 1g of chemical substances, and the unit is mg·KOH / g; the ester value (unit is mg·KOH / g)=saponification value-acid value, wherein, the saponification value represents the milligram number of potassium hydroxide consumed by the hydrol...

Embodiment 1-5

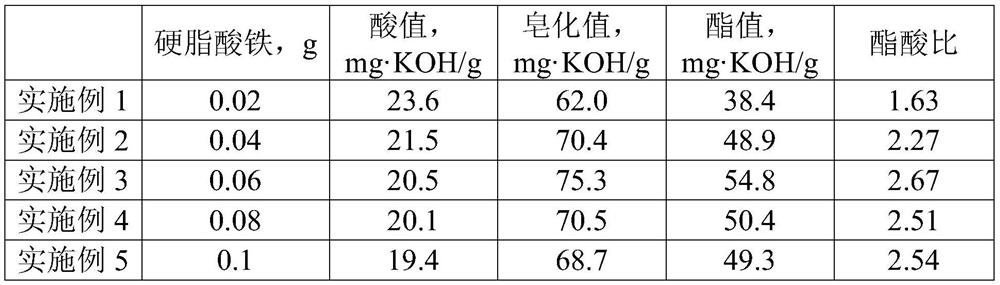

[0056] After gradually heating 100g of 70# Fischer-Tropsch wax to 120°C to melt it completely, add different masses of ferric stearate (see Table 1), 3g of glacial acetic acid and oxygen-containing gas with a gas flow rate of 50mL / min g (Oxygen content is 25v%) for catalytic oxidation, wherein the temperature of the first stage is 180°C for 1h, and the temperature of the second stage is 150°C for 6h to obtain oxidized waxes S1-S5.

[0057] Among them, the performance parameters of the acid value, saponification value, ester value and ester-acid ratio of the oxidized waxes S1-S5 are listed in Table 1; the colors of the oxidized waxes S1-S5 are similar, all of which are lighter and slightly yellowish.

[0058] Table 1

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com