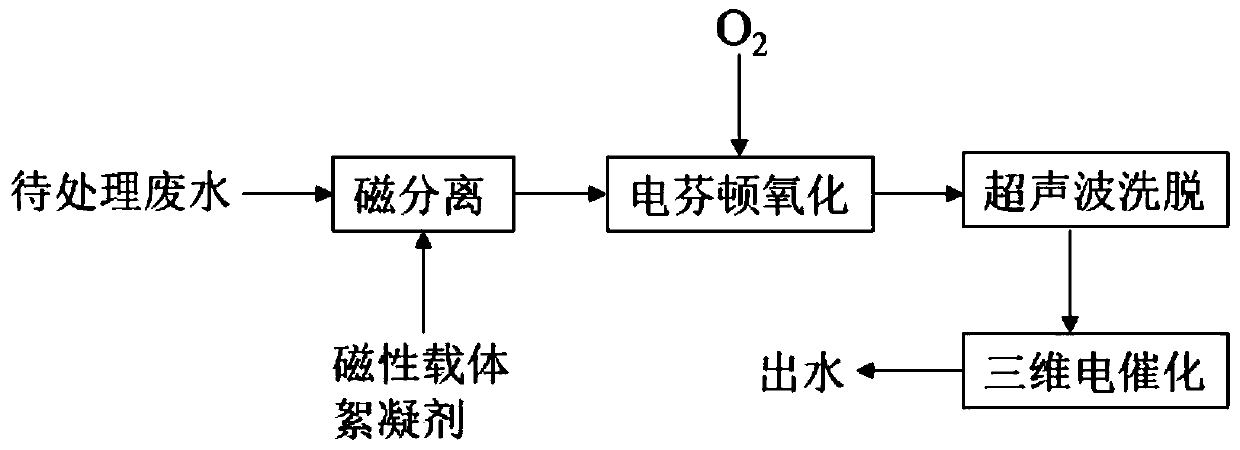

Comprehensive treatment method for high-salinity high-concentration organic wastewater

A comprehensive treatment and organic wastewater technology, applied in the field of water treatment, can solve the problems such as unsatisfactory treatment effect, achieve the effect of reducing the probability of scaling on the plate, reducing viscosity, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

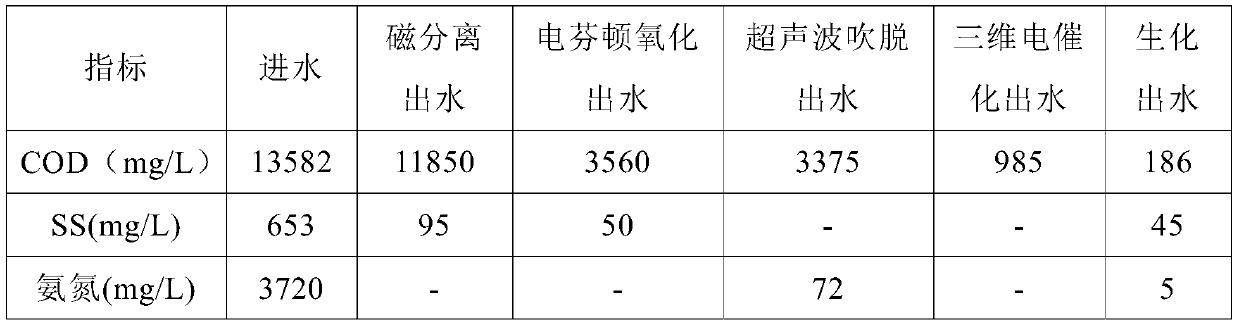

[0028] For a high-salt and high-concentration petrochemical wastewater, the total dissolved solids are 27493 mg / L, and the water quality indicators are shown in Table 1.

[0029] 2L of the waste water is introduced into the mixing reaction tank of the magnetic separation unit through the water inlet pipe, and 150mg / L magnetite and 50mg / L flocculant PAC are added to the mixing reaction tank, stirred evenly, and the power is turned on for magnetic separation treatment. The magnetic field strength is 1.5T, react for 2 hours, turn off the power, stand and separate, the solid enters the magnetic recovery system, and recovers nano-Fe 3 o 4 Reuse; waste water enters the pH adjustment pool through the outlet pipe, adjusts the pH value of the waste water to 3.5 and enters the electro-Fenton unit, turns on the power supply for electro-Fenton oxidation, the electrode used in the electro-Fenton unit is a ring structure, the cathode plate is graphite, and the anode The plate is made of me...

Embodiment 2

[0034] A high-salt and high-concentration petrochemical wastewater has a total dissolved solids of 27493mg / L, and the water quality indicators are shown in Table 2.

[0035]Put 2L of the waste water into the mixing reaction tank of the magnetic separation unit through the water inlet pipe, add 150mg / L hematite and 50mg / L flocculant PAC into the mixing reaction tank, stir evenly, turn on the power for magnetic separation treatment, and control The magnetic field strength is 1.5T, react for 1h, turn off the power, stand and separate, the solid enters the magnetic recovery system, and recovers nano-Fe 3 o 4 Reuse; waste water enters the pH adjustment tank through the outlet pipe, adjusts the pH value of the waste water to 4.0 and enters the electro-Fenton unit, turns on the power supply for electro-Fenton oxidation, the electrode used in the electro-Fenton unit is a ring structure, the cathode plate is graphite, and the anode The plate is made of metal iron, and the anode curren...

Embodiment 3

[0040] A high-salt and high-concentration petrochemical wastewater has a total dissolved solids of 27493 mg / L, and the water quality indicators are shown in Table 3.

[0041] 2L of the waste water is introduced into the mixed reaction tank of the magnetic separation unit through the water inlet pipe, and 200mg / L of nano-Fe is added to the mixed reaction tank. 3 o 4 and 50mg / L flocculant PAC, stir evenly, turn on the power for magnetic separation treatment, control the magnetic field strength to 1.0T, react for 3h, turn off the power, stand for separation, the solid enters the magnetic recovery system, recovers hematite for reuse; waste water Enter the pH adjustment tank through the outlet pipe, adjust the pH value of the wastewater to 3.0 and enter the electric Fenton unit, turn on the power supply for electric Fenton oxidation, the electrode used in the electric Fenton unit is a ring structure, the anode plate is activated fiber carbon, and the cathode plate is Metal iron, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com