Decolor refined technology of notoginseng total saponin duolite method

An ion-exchange resin and cation-exchange technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, medical preparations containing active ingredients, etc., can solve the problems of high pigment impurities and low purity of Panax notoginseng total saponins, etc. Achieve the effect of good decolorization performance, remarkable decolorization effect and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

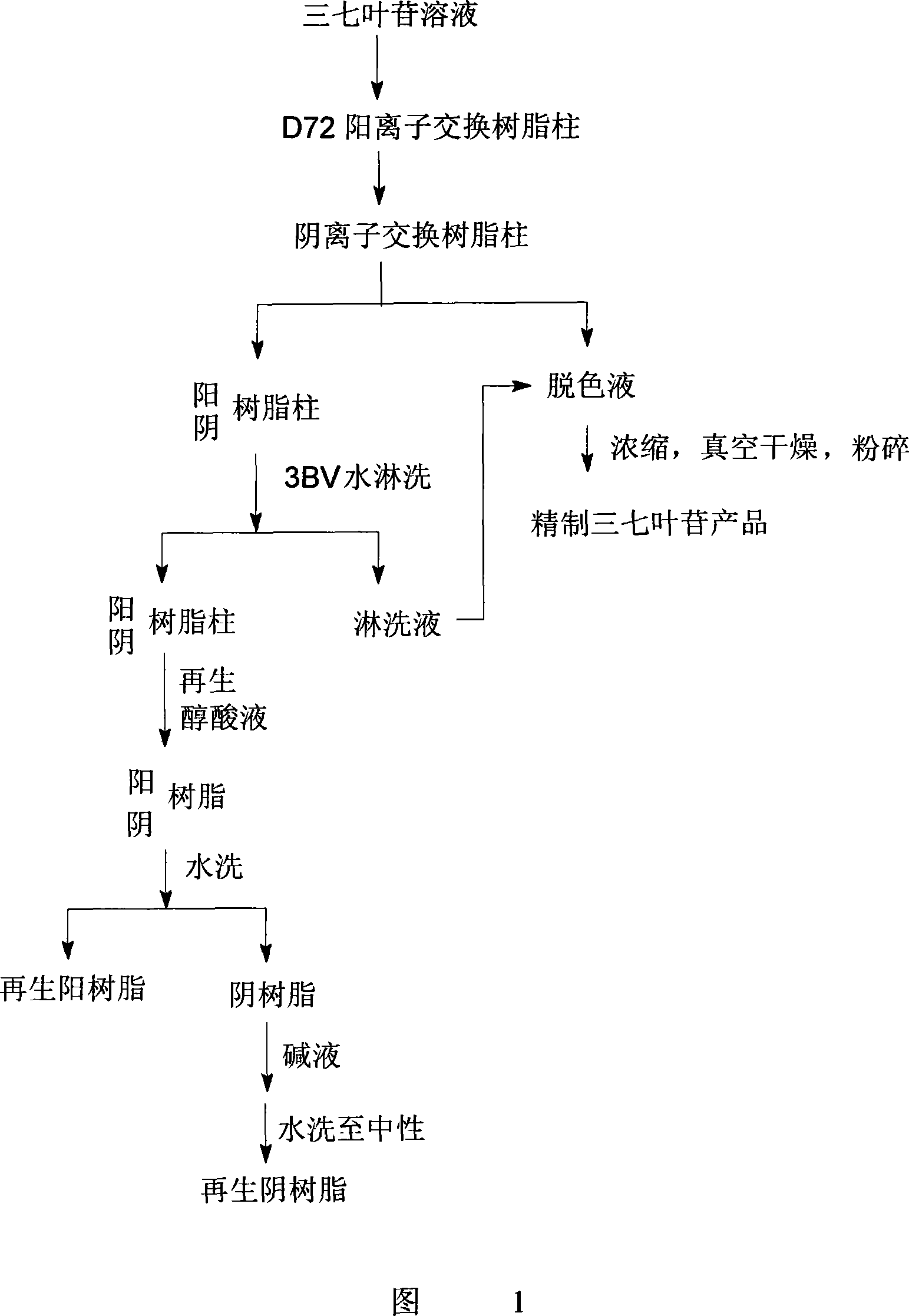

Method used

Image

Examples

Embodiment

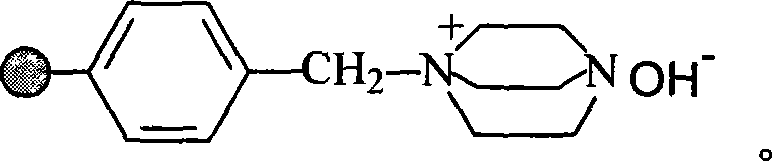

[0050] The anion exchange resin selected by the present invention is a novel resin containing strong and weak base functional groups, and its structural formula is:

[0051]

[0052] Full exchange capacity (mmol / g): 5.94

[0053] Weak base exchange capacity (mmol / g): 2.9

[0054] Moisture content: 50-60%

[0055] Granularity: 0.3-1.0

[0056] pH range: 0~14.

[0057] The specific implementation steps are:

[0058] 1 Preparation of upper column solution

[0059] Weigh 10.0 g of Panax notoginseng total saponins powder, add 20 ml of industrial ethanol and 80 ml of pure water and stir to dissolve it, and obtain the upper column liquid. Also can use the ethanol eluting concentrate after the macroporous resin adsorption from the notoginseng stem and leaf extraction process.

[0060] 2 fixed bed resin column decolorization

[0061] Pass the prepared D72 cation exchange resin column through 20ml of processed D72 cation exchange resin column, and the flow rate is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com