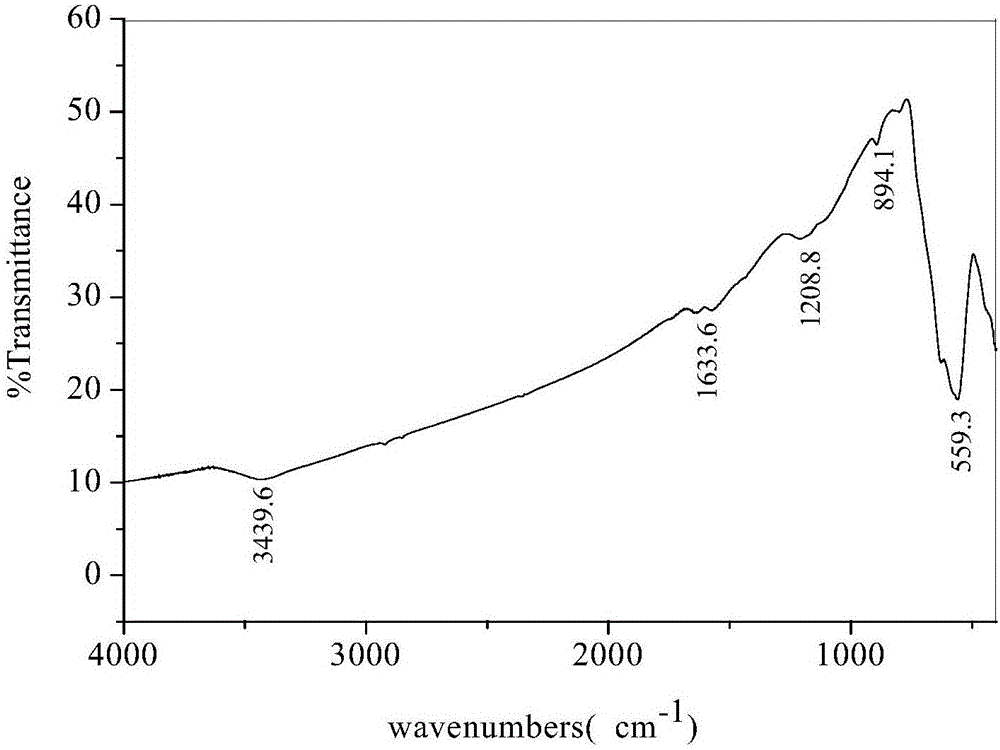

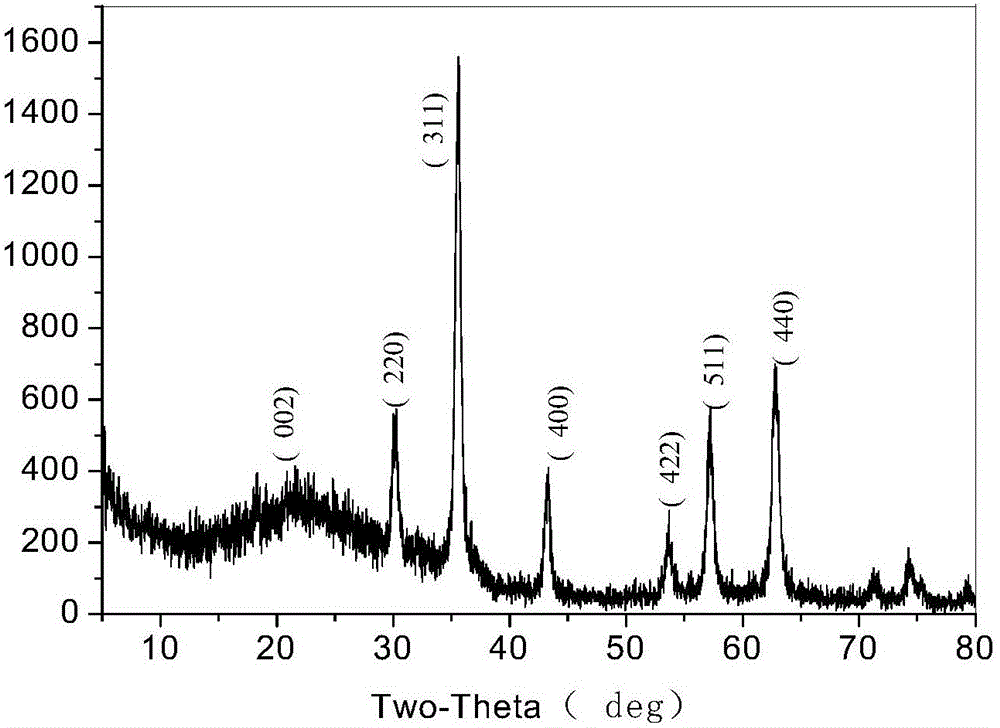

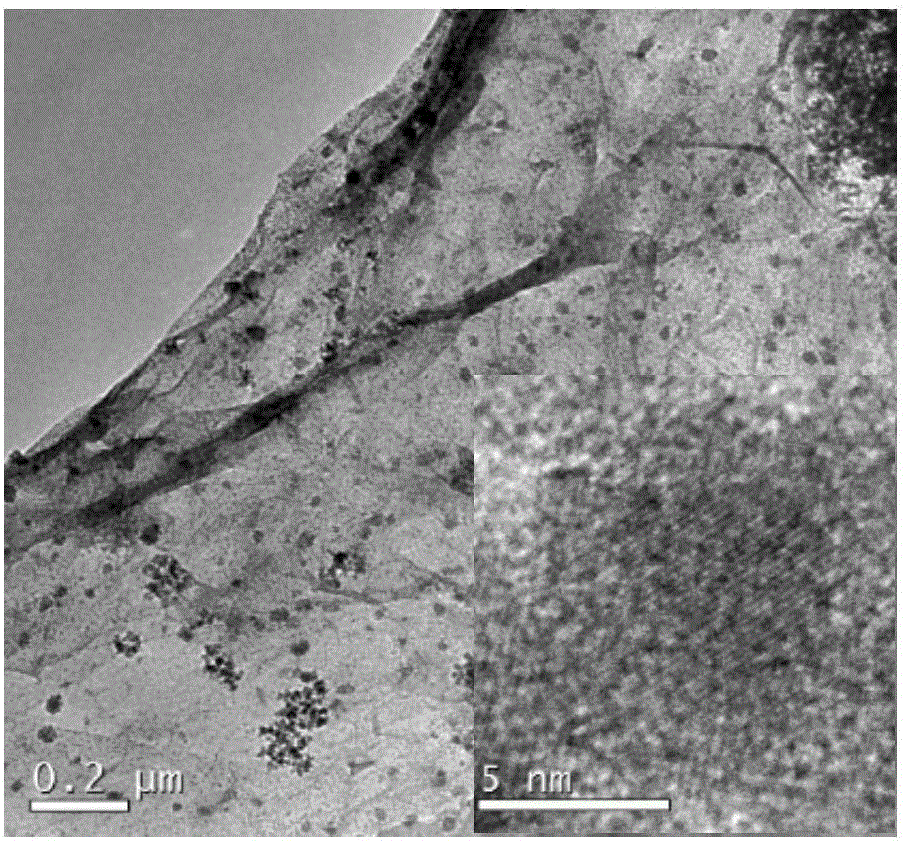

Preparation method and applications of graphene/Fe3O4 magnetic nanometer composite material

A technology of ferroferric oxide and magnetic nanometers, which is applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of high carcinogenicity and disturbing ecosystems, and achieve short reaction time and distribution The effect of uniformity and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of described graphene / ferroferromagnetic nanocomposite material, comprises the following steps:

[0031] (1) Graphene oxide is prepared by ultrasonic method:

[0032] a. According to the mass ratio of 1:300, the graphene oxide dispersion with a solid content of 2% is added to distilled water and stirred, then ultrasonicated with an ultrasonic cell pulverizer for 1 min and then centrifuged, and the upper graphene oxide solution is taken for subsequent use;

[0033] (2) Preparation of graphene / ferromagnetic nanocomposite material:

[0034] b. FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O was mixed according to the molar ratio of 1:1, then added deionized water, and stirred until fully dissolved, in which FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The mass ratio of O total mass to deionized water is 1:8;

[0035] c. Under the protection of nitrogen, the FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The aqueous solution of O was added to the graphene oxide solution stirred a...

Embodiment 2

[0040] The preparation method of described graphene / ferroferromagnetic nanocomposite material, comprises the following steps:

[0041] (1) Graphene oxide is prepared by ultrasonic method:

[0042] a. According to the mass ratio of 10:145, the graphene oxide dispersion liquid with a solid content of 3% is added to distilled water and stirred, then centrifuged after ultrasonic 5min with an ultrasonic cell pulverizer, and the upper graphene oxide solution is taken for subsequent use;

[0043] (2) Preparation of graphene / ferromagnetic nanocomposite material:

[0044] b. FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O was mixed according to the molar ratio of 2:1, then added deionized water, stirred until fully dissolved, in which FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The mass ratio of O total mass to deionized water is 6:20;

[0045] c. Under the protection of nitrogen, the FeCl 3 ·6H 2 O and FeSO 4 ·7H 2The aqueous solution of O was added to the graphene oxide solution stirred at a cons...

Embodiment 3

[0050] The preparation method of described graphene / ferroferromagnetic nanocomposite material, comprises the following steps:

[0051] (1) Graphene oxide is prepared by ultrasonic method:

[0052] a. According to the mass ratio of 5:200, the graphene oxide dispersion liquid with a solid content of 2.3% is added to distilled water and stirred, then centrifuged after ultrasonic 3min with an ultrasonic cell pulverizer, and the upper graphene oxide solution is taken for subsequent use;

[0053] (2) Preparation of graphene / ferromagnetic nanocomposite material:

[0054] b. FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O was mixed according to the molar ratio of 1.5:1, then added deionized water, and stirred until fully dissolved, wherein FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The mass ratio of O total mass to deionized water is 3:10;

[0055] c. Under the protection of nitrogen, the FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The aqueous solution of O was added to the graphene oxide solution stirred at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com