Composite flocculant and preparation method and application thereof

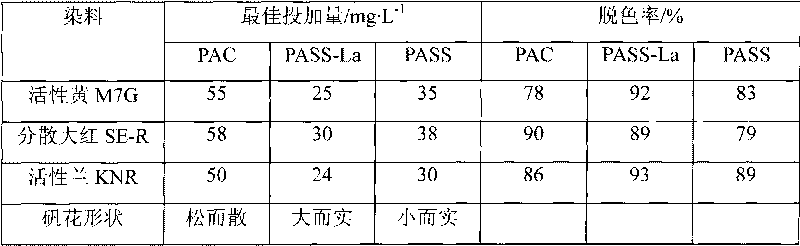

A technology of composite flocculant and flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of not being widely used, high dosage, and unsatisfactory removal of wastewater chroma, so as to achieve good coagulation effect and low dosage Less, excellent coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of polysilicon aluminum lanthanum sulfate (PASS-RE)

[0032] The polysilicoaluminum sulfate lanthanum (PASS-RE) of the present embodiment, its preparation method comprises the steps:

[0033] (1) Take by weighing 2.3 grams of lanthanum carbonate (purity 99.0%), use 7ml mass fraction 60% nitric acid, be heated to 50 ℃ and dissolve, this solution is lanthanum nitrate solution, stand-by;

[0034] (2) Take 12.3 grams of sodium silicate (purity 99%, 0.1mol), dissolve and dilute to SiO with desalted water 2 Accounting for about 5% of the total mass of the solution, then add 20% dilute H 2 SO 4 Adjust the pH value of the total system of the solution to 5.0-5.5, and stir the polymerization reaction at 30-35°C for 12-15 minutes. After the solution turns from clear to light blue, add 30.0 grams of Al 2 (SO 4 ) 3 18H 2 O (purity 96%), continue to stir until the solids are completely dissolved, then add the obtained lanthanum nitrate solution prepared...

Embodiment 2

[0036] Example 2 Preparation of polysilicate lanthanum ferric sulfate (PFSS-RE)

[0037] The polysilicon ferric lanthanum sulfate (PFSS-RE) of this embodiment, its preparation method is according to the preparation process described in Example 1, replaces aluminum sulfate octadecadecahydrate with 18.4 grams of iron sulfate (purity 98%), can make liquid poly Lanthanum ferrosilicate sulfate (Fe:Si:La molar ratio 0.9:1:0.1). The active ingredients of this liquid product are: Fe 2 o 3 4.8%, SiO 2 3.9%, La 2 o 3 1.3%, SO 4 2- 8.7%, NO 3 - 3.6%, solid content 22.8%.

Embodiment 3

[0038] Example 3 Preparation of polysilicoaluminum lanthanum cerium (PASS-Ce-La)

[0039] The polysilicoaluminum lanthanum cerium sulfate (PASS-Ce-La) of the present embodiment, its preparation method comprises the steps:

[0040] (1) Take by weighing 2.3 grams of mixed rare earth carbonate (the mass fraction of cerium carbonate is 65.3%; the mass fraction of lanthanum carbonate is 34.3%), and use 8ml mass fraction of 60% nitric acid to dissolve at 50°C. This solution is lanthanum cerium nitrate solution, ready to use;

[0041] (2) Take 12.3 grams of sodium silicate (purity 99%, 0.1mol), dissolve and dilute to SiO with desalted water 2 Accounting for about 5% of the total mass of the solution, then add dilute H with a mass fraction of 30% to the solution 2 SO 4 Adjust the pH value of the solution to 5.0-5.5, and stir the polymerization reaction at 30-35°C for 12-15 minutes. After the solution turns from clear to light blue, add 30.0 grams of Al 2 (SO 4 ) 3 18H 2 O (puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com