Method for preparing gypsum powder by microwave activation

A technology of microwave activation and gypsum powder, which is applied in the field of preparation of industrial gypsum powder, can solve the problems affecting the appearance of downstream products, the color of desulfurized gypsum is black, etc., and achieve the effects of saving a lot of mining, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

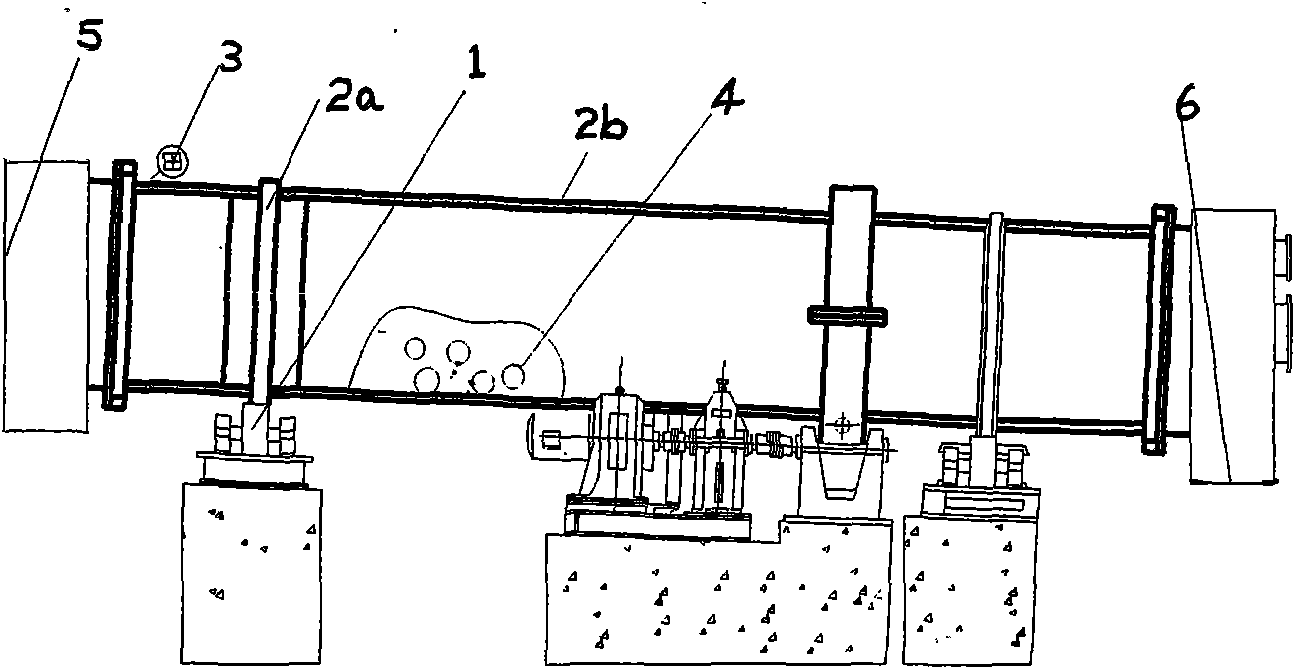

Embodiment 1

[0015] Embodiment 1: The desulfurized gypsum with dihydrate gypsum as the main component obtained from the desulfurization treatment of a coal-fired power plant, by weight percentage desulfurized gypsum 70%: modifier 15%: bleaching agent 15% at about 150 ℃ unsaturated gypsum Mix in the steam medium, and then send the mixed material into the glass fiber reinforced plastic cylinder 2b of the microwave equipment. With the rotation of the outer stainless steel rotating body 2a of the drum, the inner glass fiber reinforced plastic cylinder 2b is driven to rotate, so that the mixed material is microwave dried and dehydrated At the same time, it is turned together with the ball mill body 4 in the working chamber of the microwave equipment to grind each other, and the mixture is ground to obtain gypsum powder while drying and dehydrating. Finally, send the gypsum powder to the microwave equipment for natural cooling and aging. The modifier is prepared by compounding isobutyric acid an...

Embodiment 2

[0016] Embodiment 2: 90% of desulfurized gypsum by weight percentage: modifier 5%: bleaching agent 5% is mixed in an unsaturated steam medium not higher than 180°C, and then the mixture is sent into the glass fiber reinforced plastic cylinder 2b, and then The glass fiber reinforced plastic cylinder 2b is rotated so that the mixed material is ground while being dried and dehydrated to obtain gypsum powder. Finally, send the gypsum powder out of the microwave equipment for cooling. The modifier is prepared by compounding lauric acid and calcium sulfate according to the medium concentration of 1:1. Bleach is prepared by compounding hydrogen peroxide and sodium hypochlorite at a ratio of 80:1. The filling factor of the mixture into the microwave equipment is 0.7, the drying and dehydration temperature is 150°C, and the power density of the microwave feeding is controlled at 4.5kW / m 3 , residence time 180min. The fineness of the prepared gypsum powder requires a 180-mesh sieve w...

Embodiment 3

[0017] Embodiment 3: 80% of desulfurized gypsum by weight percentage: modifier 10%: bleaching agent 10% is mixed in an unsaturated steam medium not lower than 120°C, and then the mixture is sent into the glass fiber reinforced plastic cylinder 2b, and then The glass fiber reinforced plastic cylinder 2b is rotated so that the mixed material is ground while being dried and dehydrated to obtain gypsum powder. Finally, send the gypsum powder out of the microwave equipment for cooling. The modifying agent was prepared by compounding hexivalic acid and potassium sulfate according to the medium concentration of 1:1. Bleach is prepared by compounding hydrogen peroxide and sodium hypochlorite at a ratio of 50:1. The filling coefficient of the mixture into the microwave equipment is 0.65, the drying and dehydration temperature is 130°C, and the power density of the microwave feeding is controlled at 4.0kW / m 3 , The residence time is about 150min. The fineness of the prepared gypsum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com