Graphene oxide/red phosphorus composite material as well as preparation method and application thereof

A composite material and graphene technology, applied in the field of photocatalysis, can solve the problems affecting the photocatalytic performance of red phosphorous and low crystallization degree, and achieve excellent photocatalytic performance, improved decolorization ability, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

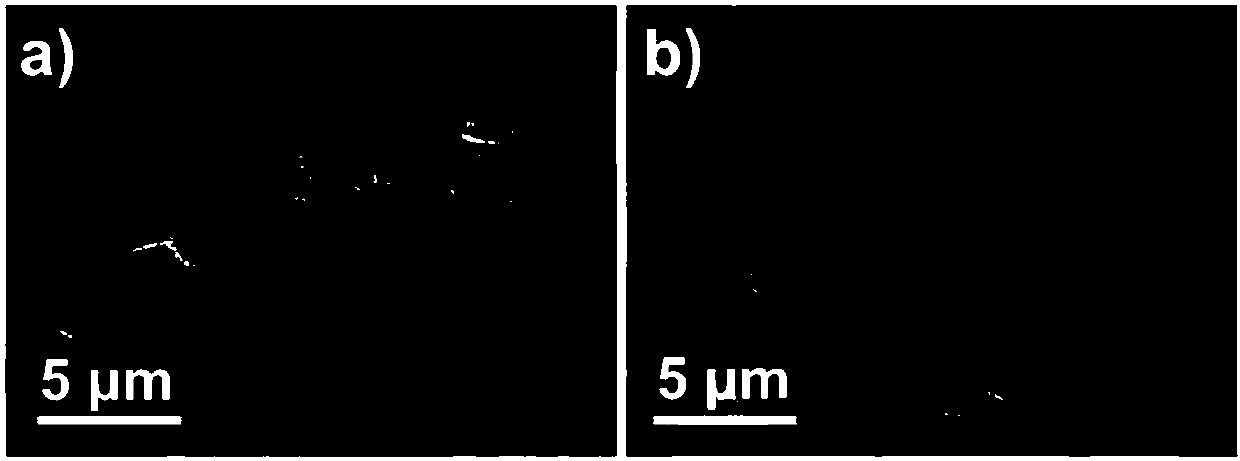

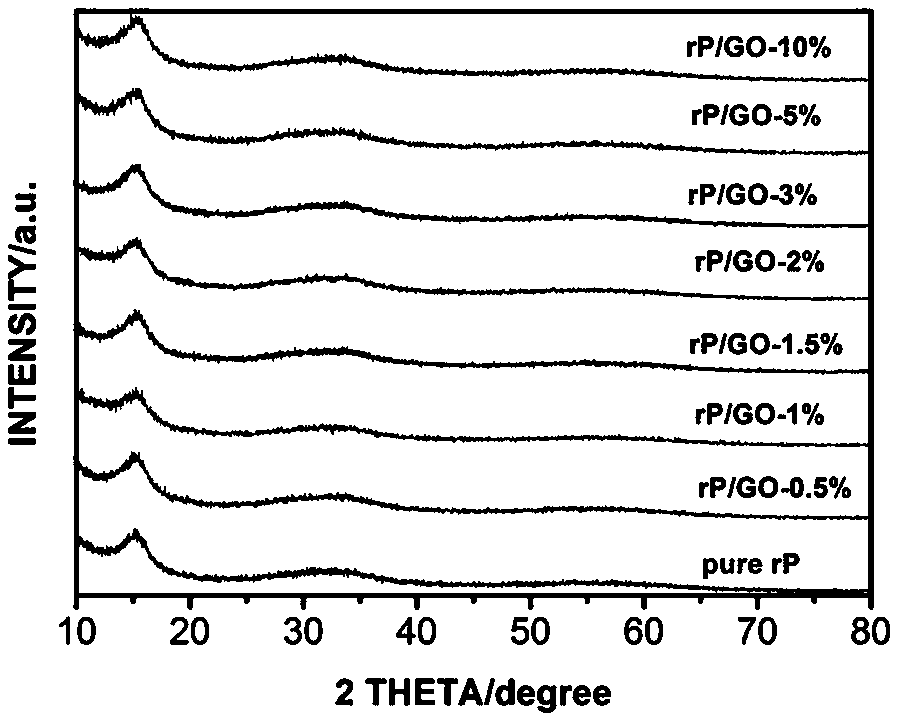

[0041] Preparation of Nanoscale Graphene Oxide / Red Phosphorous Composite

[0042] First, 10g of red phosphorus is added to the ethanol dispersion of 0.1g / L nano-graphene oxide at a concentration of 100ml, and after stirring evenly, the above-mentioned dispersion is placed in a constant temperature ultrasonic water bath for 10 hours under dark conditions (ultrasonic power 300W), maintain the temperature below 25 degrees during ultrasonic treatment.

[0043] Subsequently, the ultrasonically treated solution was centrifuged at a rate of 500 r / min, filtered to obtain a dark red solid, washed three times with ethanol, dried at 60°C for 5 hours in a blast drying oven, and cooled to room temperature naturally 0.1% doped graphene oxide / red phosphorus composite material can be obtained, denoted as rP / GO-0.1%.

Embodiment 2

[0045] Preparation of Nanoscale Graphene Oxide / Red Phosphorous Composite

[0046] First, the concentration of 10g red phosphorus is added to the ethanol dispersion of 0.5g / L nano-graphene oxide in the concentration of 100ml, and after stirring evenly, the above-mentioned dispersion is placed in an ultrasonic water bath for 8 hours under dark conditions (ultrasonic power: 300W), maintain the temperature below 25 degrees during ultrasonic treatment.

[0047] Subsequently, the ultrasonically treated solution was centrifuged at a rate of 500 r / min, filtered to obtain a dark red solid, washed three times with ethanol, dried at 60°C for 5 hours in a blast drying oven, and cooled to room temperature naturally 0.5% doped graphene oxide / red phosphorus composite material can be obtained, denoted as rP / GO-0.5%.

Embodiment 3

[0049] Preparation of Nanoscale Graphene Oxide / Red Phosphorous Composite

[0050] First, 10g red phosphorus is added to the concentration of 100ml in the ethanol dispersion of nano-graphene oxide of 1 g / L, and after stirring evenly, the above-mentioned dispersion is placed in an ultrasonic water bath for 8 hours under dark conditions (ultrasonic power: 300W), maintain the temperature below 25 degrees during ultrasonic treatment.

[0051] Subsequently, the ultrasonically treated solution was centrifuged at a rate of 500 r / min, filtered to obtain a dark red solid, washed three times with ethanol, dried at 60°C for 5 hours in a blast drying oven, and cooled to room temperature naturally 1% doped graphene oxide / red phosphorus composite material can be obtained, denoted as rP / GO-1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com