Organic silicon hardening liquid with photocatalyst function and preparation method thereof

A technology of organosilicon and hardening fluid, applied in the direction of coating, etc., to achieve high transparency, ensure hardness and friction resistance, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0027] The wetting and leveling agent used in the examples is BYK-333, and the rest of the raw materials are commercially available industrial products unless otherwise specified, and can be purchased through commercial channels.

[0028] Coating properties are measured using the following methods:

[0029] The hardness is measured by Chinese pencil according to the method of GB / T1730-1993, and the light transmittance is tested by UV-Vis spectrum. The PMMA board without coating is used as a blank.

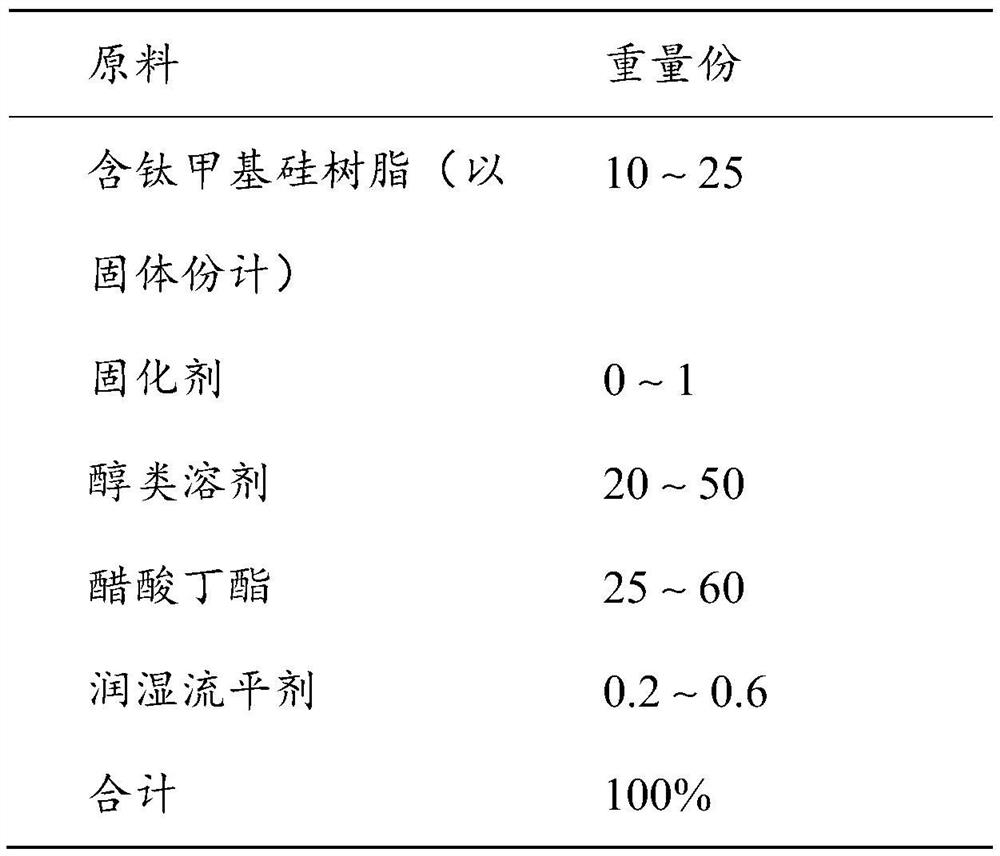

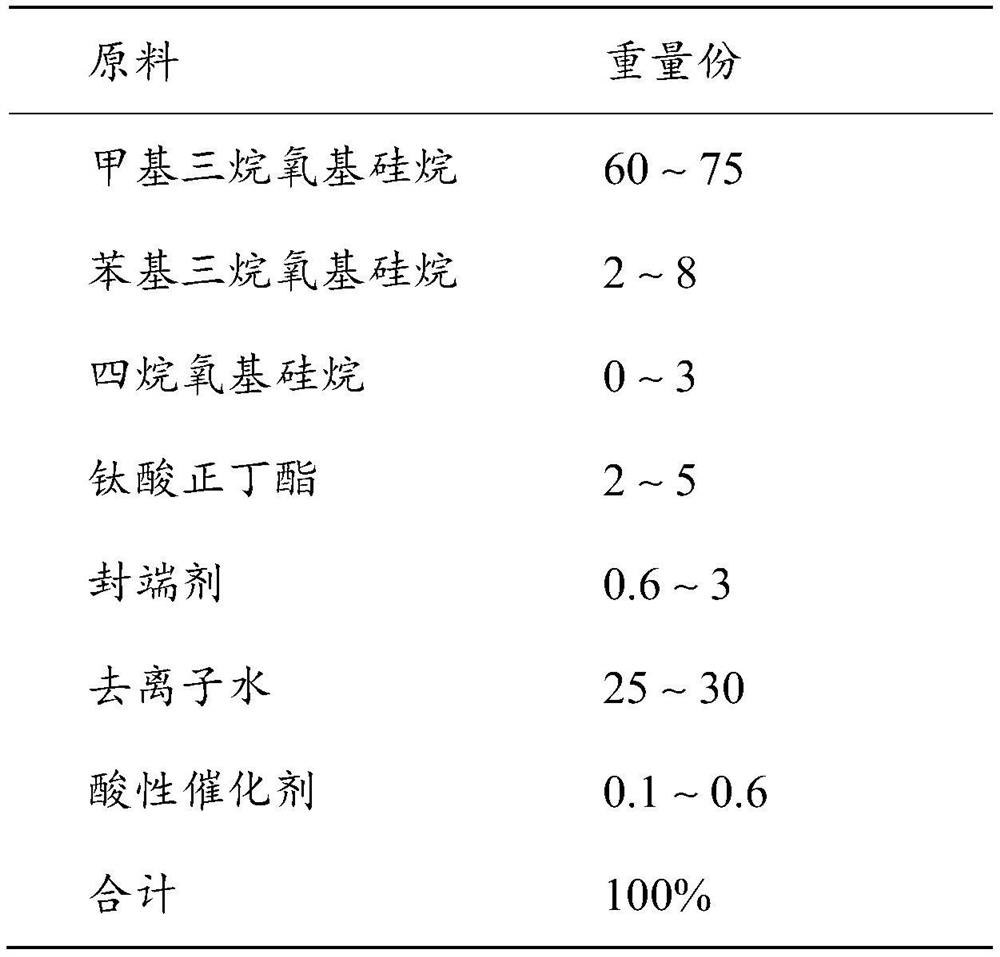

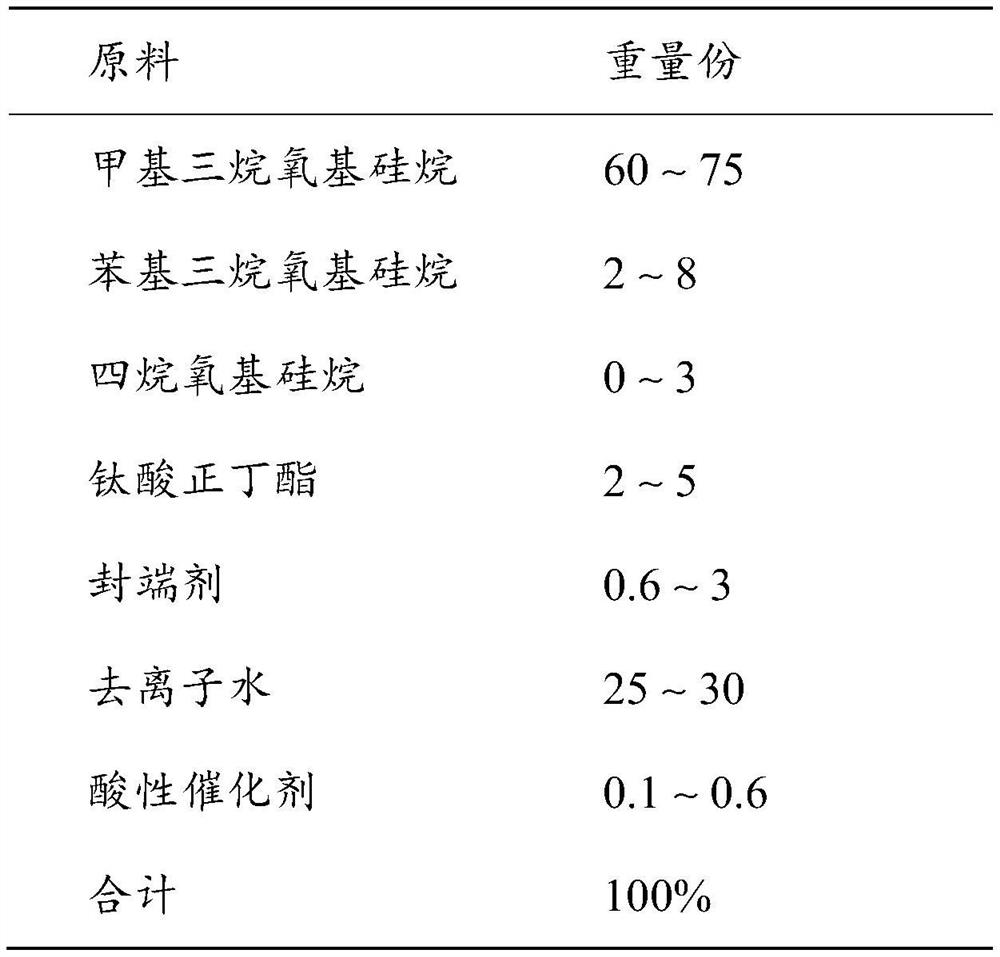

[0030] (1) Synthesis and screening of titanium-containing methyl silicone resin

[0031] According to the proportion shown in Table 1, add deionized water and acidic catalyst into the reaction vessel, and stir evenly. After mixing the siloxane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com