Method for preparing copper/nitrogen co-doped titanium dioxide nanometer powder based on dry gel-alcohol thermal method

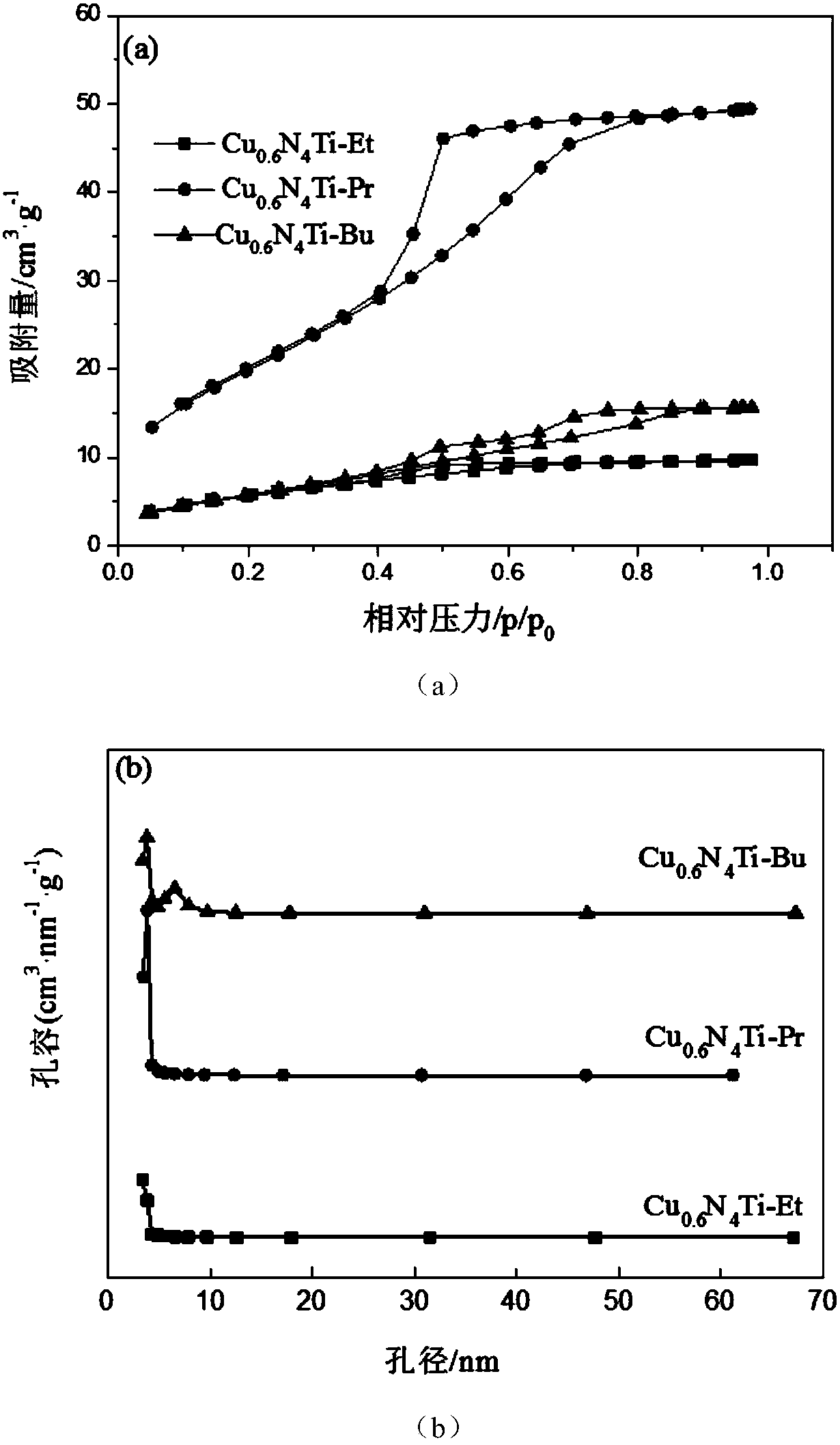

A technology of titanium dioxide and nanopowder, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of amorphous crystallization and poor quality of samples, and achieve good photocatalytic performance and increase The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

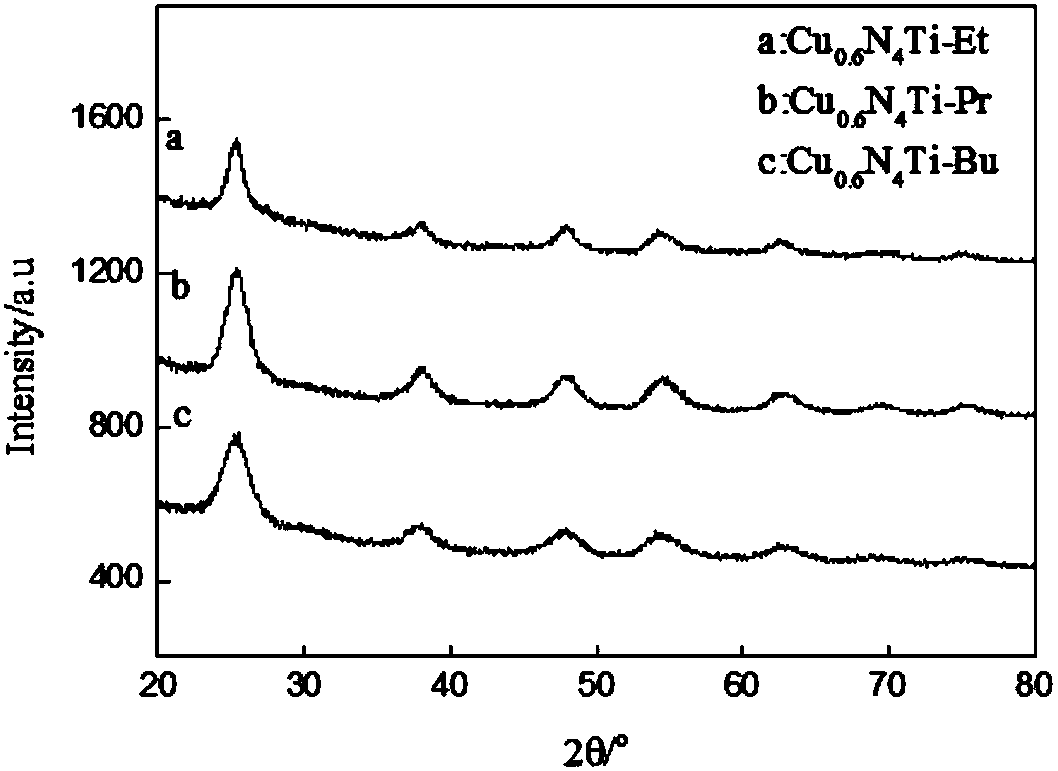

[0037] Cu 0.6 N 4 / TiO 2 The preparation of nanopowder photocatalyst comprises the following steps:

[0038] (1) Solution preparation:

[0039] Solution A: Mix 8.5mL butyl titanate with 30mL absolute ethanol, and stir mechanically at room temperature to form a transparent solution.

[0040] Solution B: Accurately weigh a certain amount of copper nitrate and urea, and dissolve them in a mixed solution of 1.5mL triple-distilled water, 15mL absolute ethanol and 1mL concentrated nitric acid solution. Addition of selected Cu elements (Cu / TiO 2 mass ratio) is 0.6wt%. Addition of selected N elements (N / TiO 2 The mass ratio of is 4wt%).

[0041] (2) Sol process: Slowly drop liquid B into liquid A at a rate of 30 drops / min through a peristaltic pump until a transparent sol is formed. The reaction temperature is room temperature.

[0042] (3) Gel process: After forming a sol, it is aged at room temperature, and the obtained Cu 0.6 N 4 / TiO 2 The gel was dried in an air-blast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com