Preparation method of ZnFe2O4 nanoparticles used for air purifier

An air purifier and nanoparticle technology, which is applied in the field of preparation of ZnFe2O4 nanoparticles for air purifiers, can solve the problems of low photocatalytic activity and the like, and achieve the effects of simple and easy operation, low cost and good photocatalytic performance of the preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

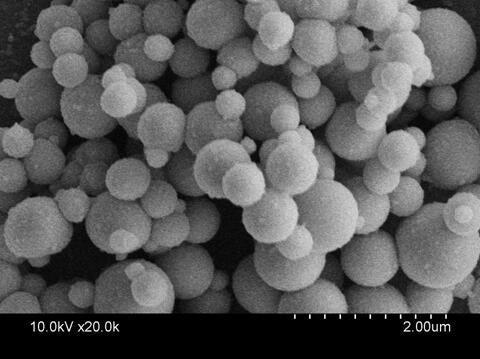

Image

Examples

Embodiment 1

[0025] FeCl 3 / Fe 2 (SO4) 3 Dissolve in 50ml deionized water at a molar ratio of 1:1, Fe + The concentration is 0.5mol L -1 ; Add 1mol·L drop by drop -1 NaOH solution, and observe the Tyndall effect of the solution until the reddish-brown transparent Fe(OH) 3 Hydrosol.

[0026] In the configured Fe(OH) 3 Add 0.5mol·L to the hydrosol -1 Sodium dodecylbenzenesulfonate (ABS) solution to make the sol coagulate. After washing the precipitate, place it for 30d. Then, it was dried under nitrogen atmosphere at 50 °C to obtain uniformly dispersed FeOOH nanoparticles.

[0027] Place the obtained FeOOH powder in 0.1mol L -1 Soak in diethyl zinc solution for 30min; repeat the soaking process 5 times to deposit the ZnO layer on the surface of FeOOH. Finally, the soaked FeOOH / ZnO powder was put into a muffle furnace and annealed at 520 °C for 3 hours.

[0028] Calcined powder at 0.05mol L -1 Soak in KOH solution for 5 minutes to remove excess ZnO and finally get pure ZnFe 2 o...

Embodiment 2

[0030] FeCl 3 / Fe 2 (SO4) 3 Dissolve in 50ml deionized water at a molar ratio of 1:2, Fe + The concentration is 0.5mol L -1 ; Add 1mol·L drop by drop -1 NaOH solution, and observe the Tyndall effect of the solution until the reddish-brown transparent Fe(OH) 3 Hydrosol.

[0031] In the configured Fe(OH) 3 Add 0.5mol·L to the hydrosol -1 Sodium dodecylbenzenesulfonate (ABS) solution to make the sol coagulate. After washing the precipitate, place it for 30d. Then, it was dried under nitrogen atmosphere at 200 °C to obtain uniformly dispersed FeOOH nanoparticles.

[0032] Place the FeOOH powder prepared in (2) in 0.1mol L -1 Soak in diethyl zinc solution for 30min; repeat the soaking process 5 times to deposit the ZnO layer on the surface of FeOOH. Finally, the soaked FeOOH / ZnO powder was put into a muffle furnace and annealed at 520°C for 3 hours.

[0033] Calcined powder at 0.05mol L -1 Soak in KOH solution for 5 minutes to remove excess ZnO and finally get pure Zn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com