A highly photocatalytically active cati 2 o 5 Preparation method of nanoparticles and the products obtained therefrom

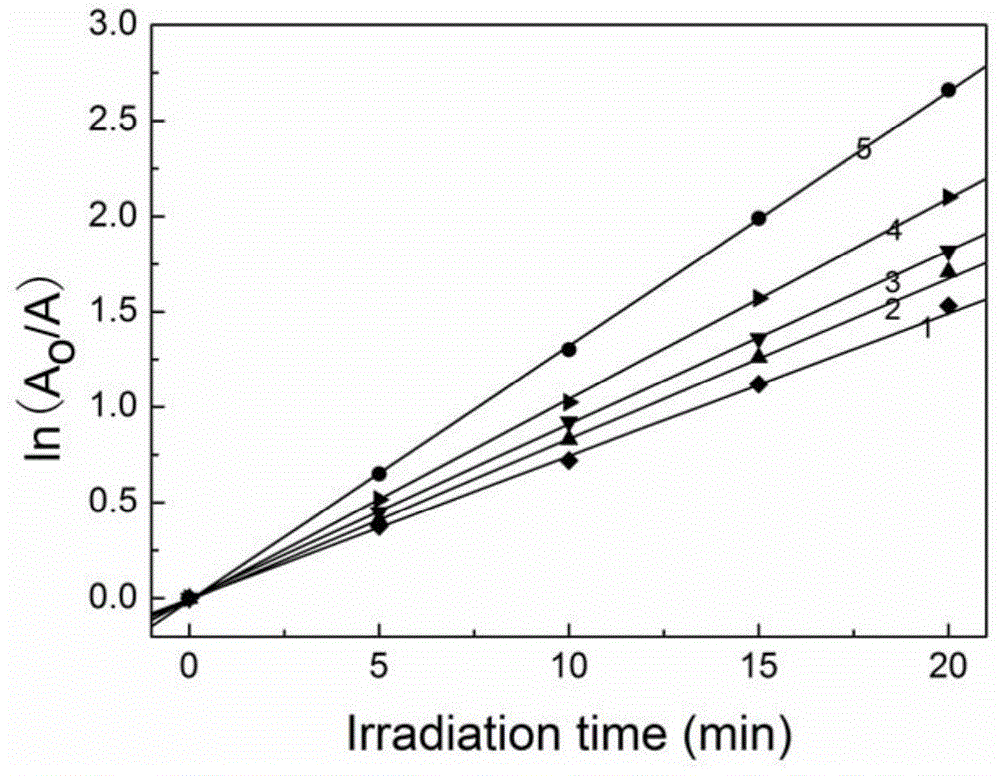

A nanoparticle, catalytic activity technology, applied in the field of photocatalysis, can solve problems such as blank, difficult synthesis, complex process, etc., and achieve the effect of simple process route, promotion of application and development, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

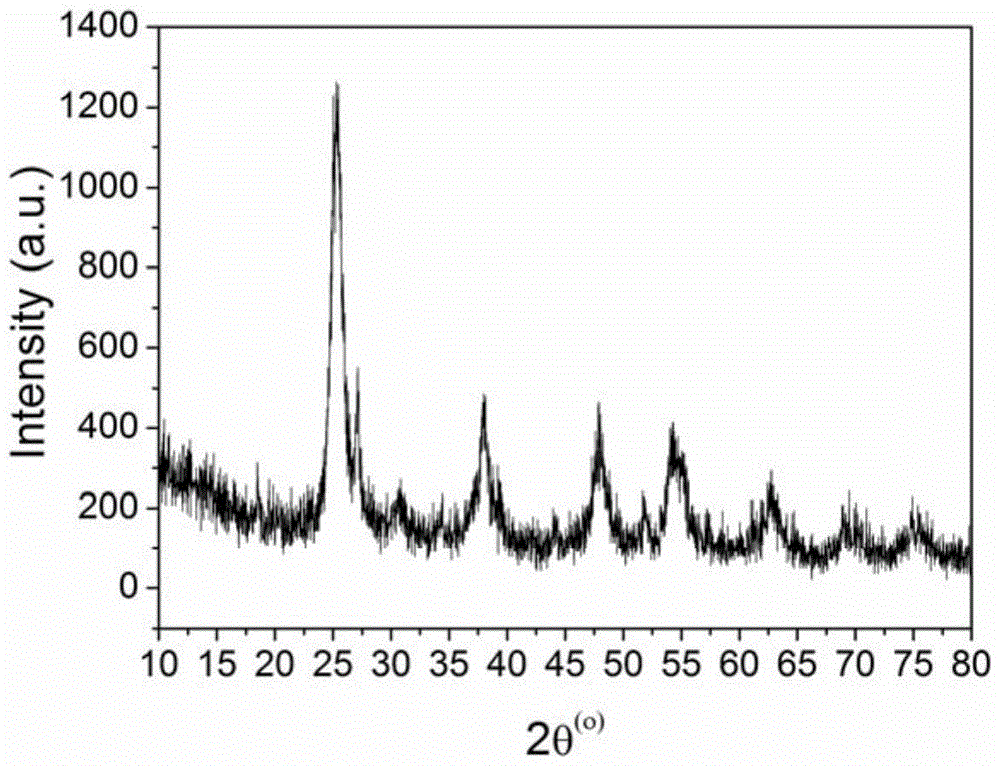

[0021] In this embodiment, high photocatalytic activity CaTi 2 o 5 The preparation method of nanoparticle, its step is as follows:

[0022] (1) Dissolve butyl titanate in ethanol, according to the molar ratio of butyl titanate: ethanol = 1:5, stir until uniform to obtain A solution;

[0023] (2) Calcium chloride pentahydrate is dissolved in distilled water, then add ethanol, according to molar ratio calcium chloride pentahydrate: distilled water: ethanol=1: 400: 10, stir to obtain B solution evenly;

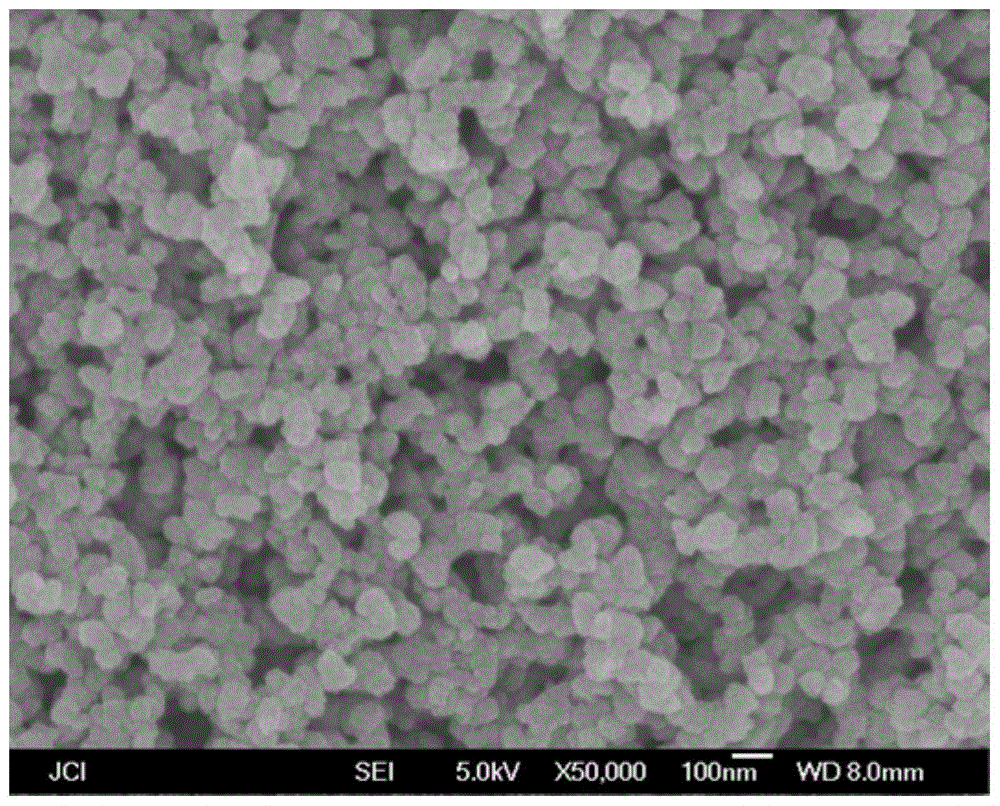

[0024] (3) Add solution A dropwise into solution B under stirring and stir and mix for 10 minutes, then gradually add hydrochloric acid solution dropwise to pH 4.5, and continue stirring for 15 minutes; Insulate at ℃ for 36h, wash with distilled water 6 times, and obtain CaTi with a particle size of 50nm 2 o 5 nanoparticles.

Embodiment 2

[0026] In this embodiment, high photocatalytic activity CaTi 2 o 5 The preparation method of nanoparticle, its step is as follows:

[0027] (1) Dissolving isopropyl titanate in propanol, according to the molar ratio of isopropyl titanate:propanol=1:5, stirred until uniform to obtain A solution;

[0028] (2) Calcium chloride pentahydrate is dissolved in distilled water, then propanol is added, according to molar ratio calcium chloride pentahydrate: distilled water: propanol=1: 400: 1, stir until evenly obtain B solution;

[0029] (3) Add solution A dropwise to solution B under stirring and stir and mix for 5 minutes, then gradually add hydrochloric acid solution dropwise until the pH value is 4.5, and continue stirring for 15 minutes; Insulate at ℃ for 24h, wash with distilled water 3 times to obtain CaTi with a particle size of 65nm 2 o 5 nanoparticles.

Embodiment 3

[0031] In this embodiment, high photocatalytic activity CaTi 2 o 5 The preparation method of nanoparticle, its step is as follows:

[0032] (1) Dissolving titanium chloride in butanol, according to the molar ratio of isopropyl titanate:butanol=1:1, stirred until uniform to obtain A solution;

[0033] (2) Calcium chloride pentahydrate is dissolved in distilled water, then add butanol, according to molar ratio calcium chloride pentahydrate: distilled water: butanol=1: 400: 5, stir to obtain B solution evenly;

[0034] (3) Add solution A dropwise to solution B under stirring and stir and mix for 8 minutes, then gradually add sulfuric acid solution dropwise to a pH value of 4.9, and continue stirring for 15 minutes; Incubate at ℃ for 18h, wash 6 times with distilled water, and obtain CaTi with a particle size of 60nm 2 o 5 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com