Method for degrading methylene blue solution

A methylene blue solution technology, applied in the field of water treatment, can solve problems such as low catalytic efficiency, refractory degradation, and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

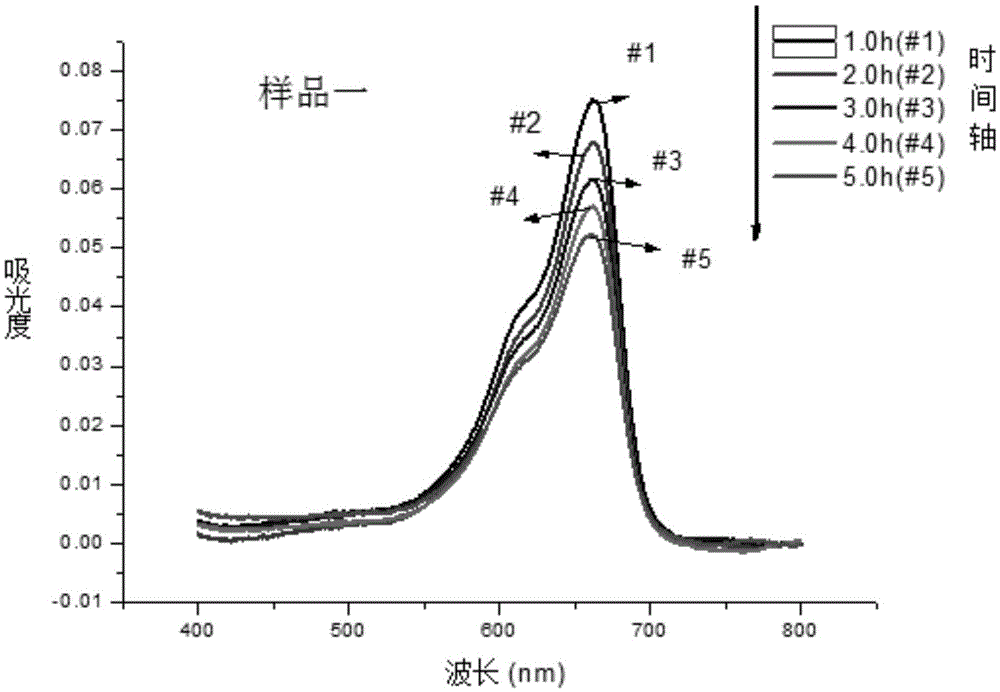

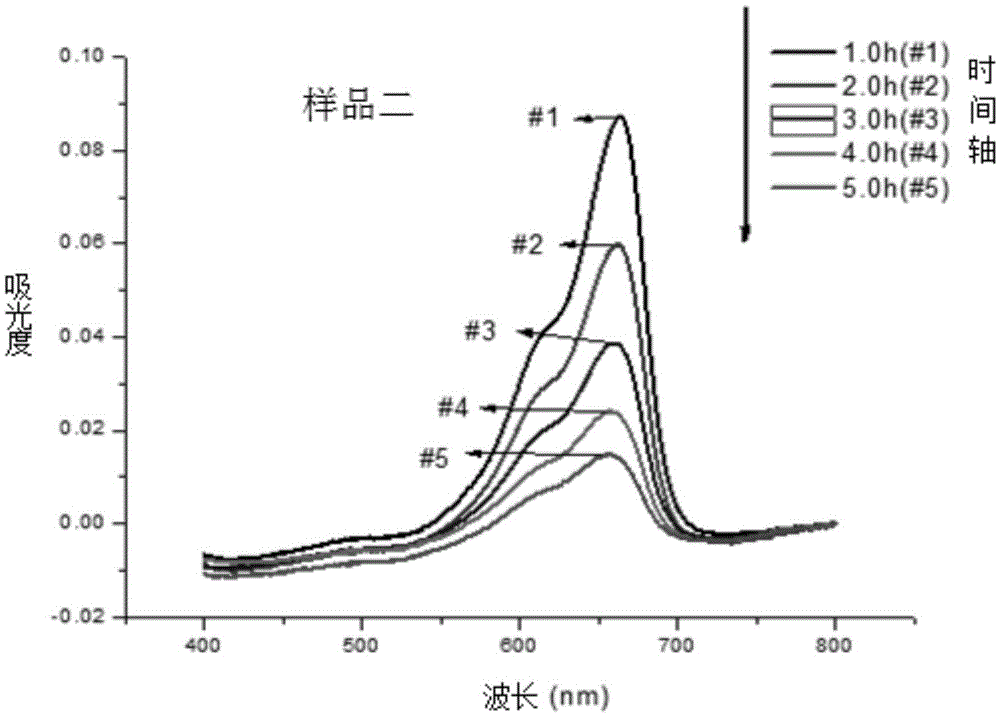

[0019] The invention discloses a method for degrading a methylene blue solution, which uses CuO as a catalyst to catalyze the decomposition of the methylene blue solution by hydrogen peroxide. This method is referred to as the HCW method.

[0020] In the present invention, commercial pure CuO powder can be used as CuO.

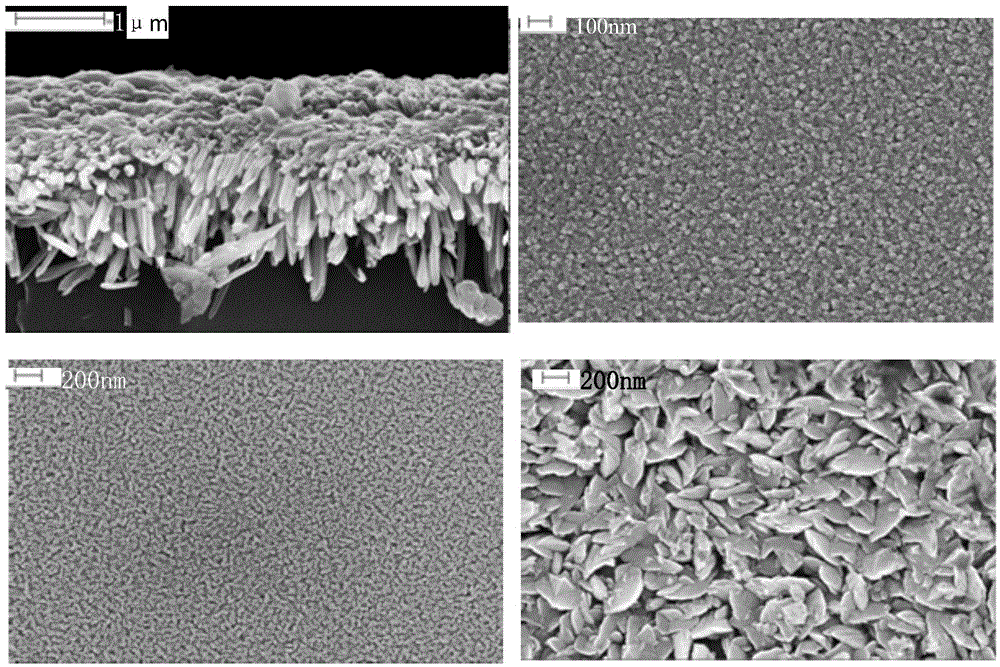

[0021] As an optimized choice, in the present invention, the CuO adopts a nanostructured CuO thin film. The nano-structured CuO thin film adopts commercial pure Cu as the target material, takes the quartz thin film as the substrate, and uses the magnetron and evaporation coating device to carry out the magnetron sputtering coating.

[0022] In the present invention, the preparation method of the CuO film of nanostructure is as follows:

[0023] (1) Prepare the substrate

[0024] A quartz film with a thickness of 1 mm is used as the substrate, and the substrate needs to be thoroughly cleaned in order to avoid contamination. First use a dust-free cloth and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com