Multi-stage rotational flow separation and filtering device with opposite rotational flows and use method

A cyclone separation technology with opposite swirl directions, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem that the discharged substances cannot achieve environmental protection, energy saving, reduce the separation efficiency of the cyclone, and block the bottom flow pipe of the cyclone. and other problems, to achieve the effect of shortening the separation distance, reducing the flow speed, and enhancing the swirl torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

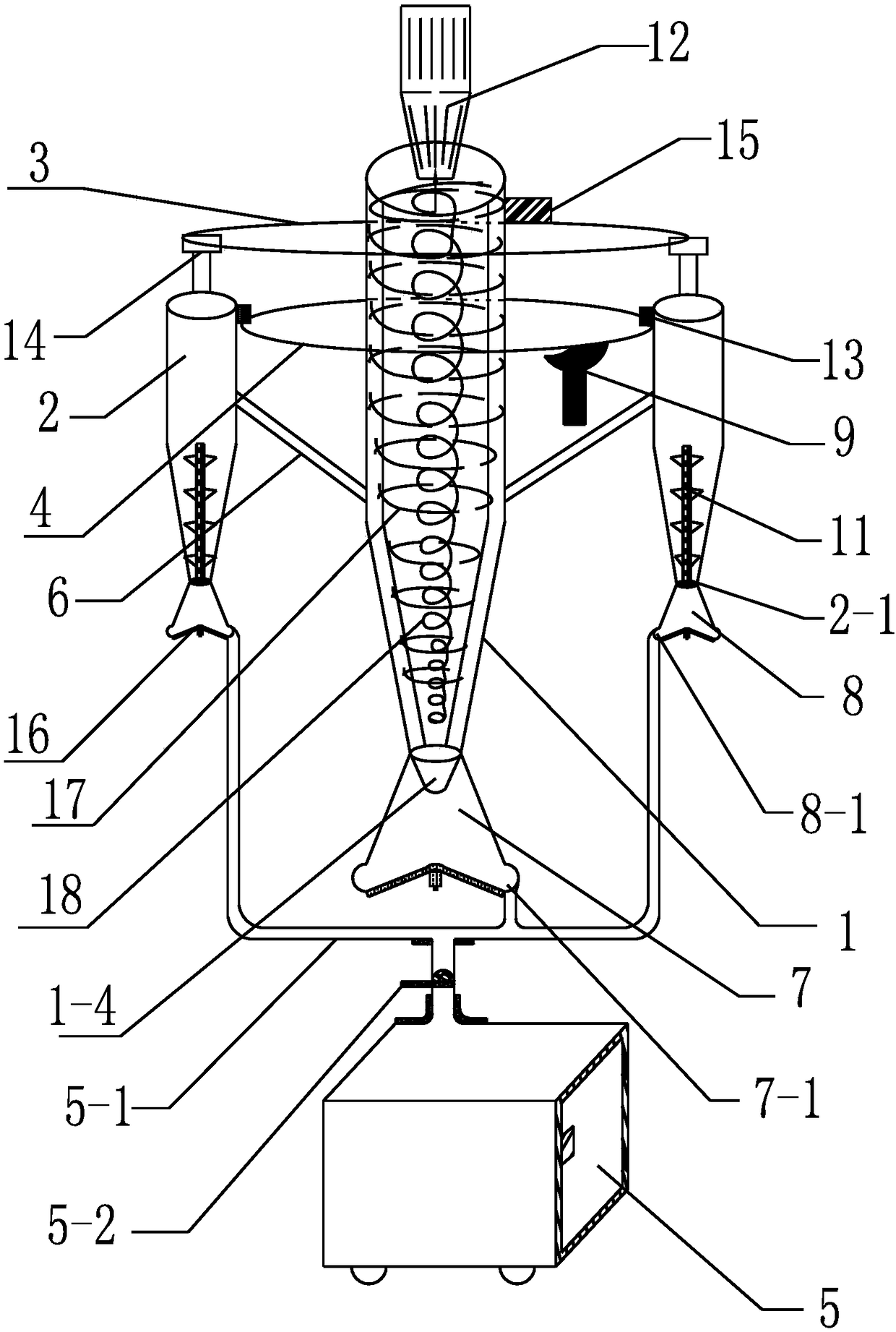

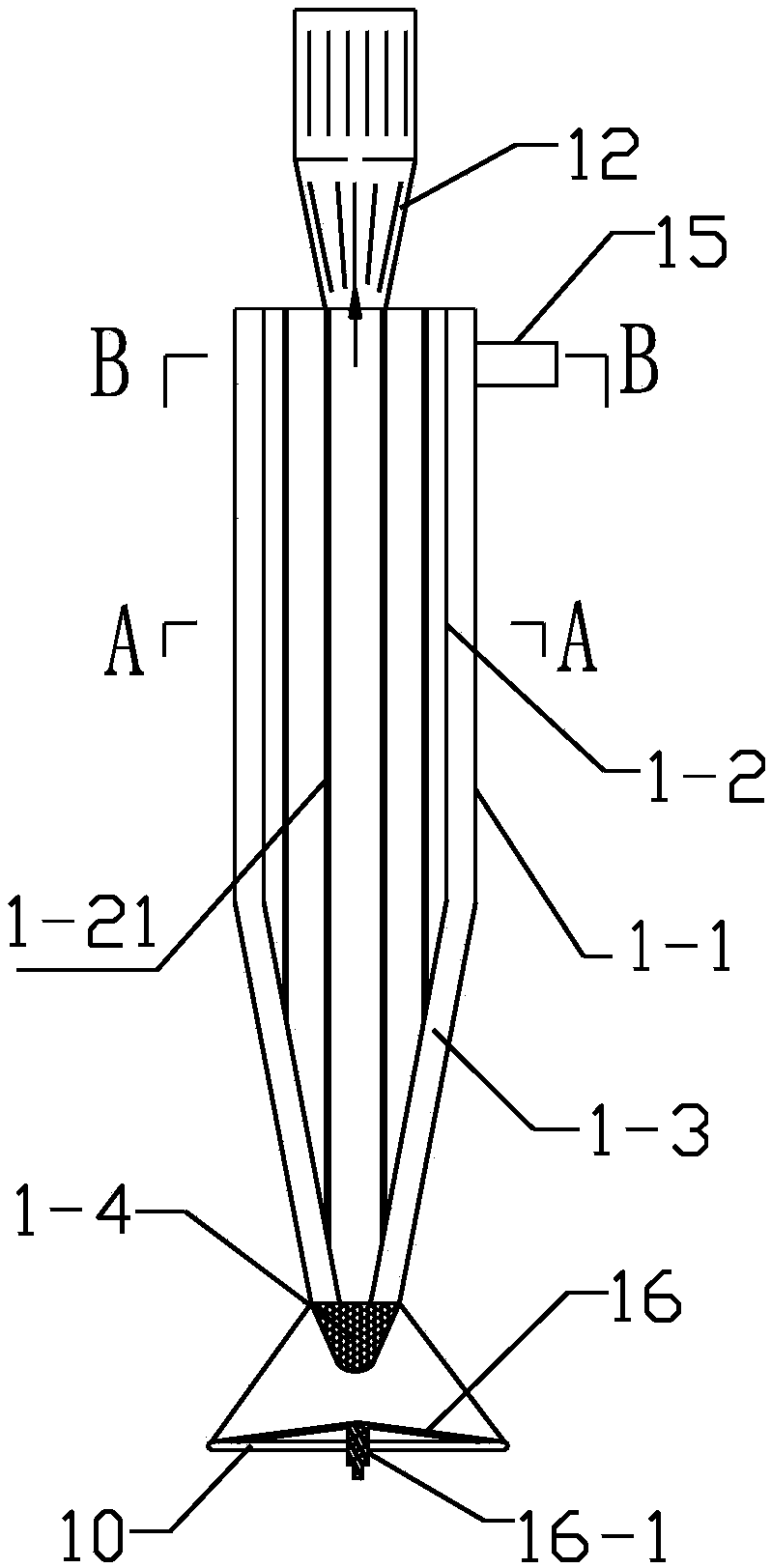

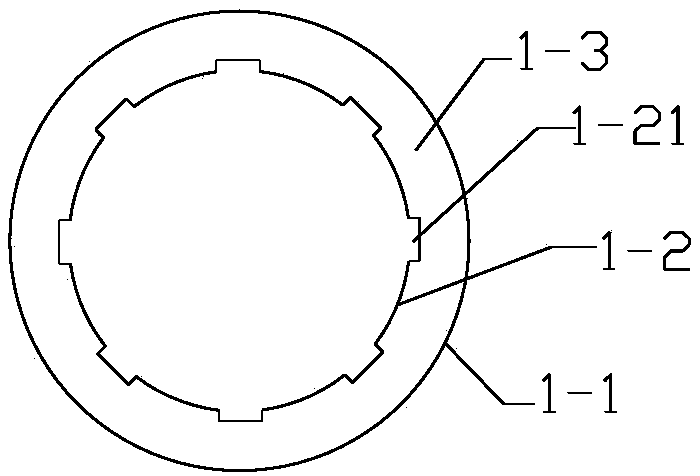

[0047] Such as figure 1 As shown, the device for multi-stage cyclone separation and filtration with opposite direction of rotation is characterized in that: the device includes a main cyclone separation drum 1, a primary separation and filtration device, an annular feed guide pipe 4 and an annular liquid outlet Guide pipe 3, the primary separation and filtering device includes at least two secondary cyclone separation cylinders 2, the plurality of secondary cyclone separation cylinders 2 are equidistantly distributed on the outer circumference of the main cyclone separation cylinder 1, each secondary cyclone separation The cylinder body of the cylinder 2 is fixedly connected with the cylinder body of the main cyclone separation cylinder 1 through the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com