Method for catalytically degrading phthalate pollutant by directly utilizing sunlight

A phthalate ester, catalytic degradation technology, applied in the direction of water pollutants, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of accelerating the degradation process, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for directly utilizing sunlight to catalyze the degradation of phthalate pollutants, comprising the steps of:

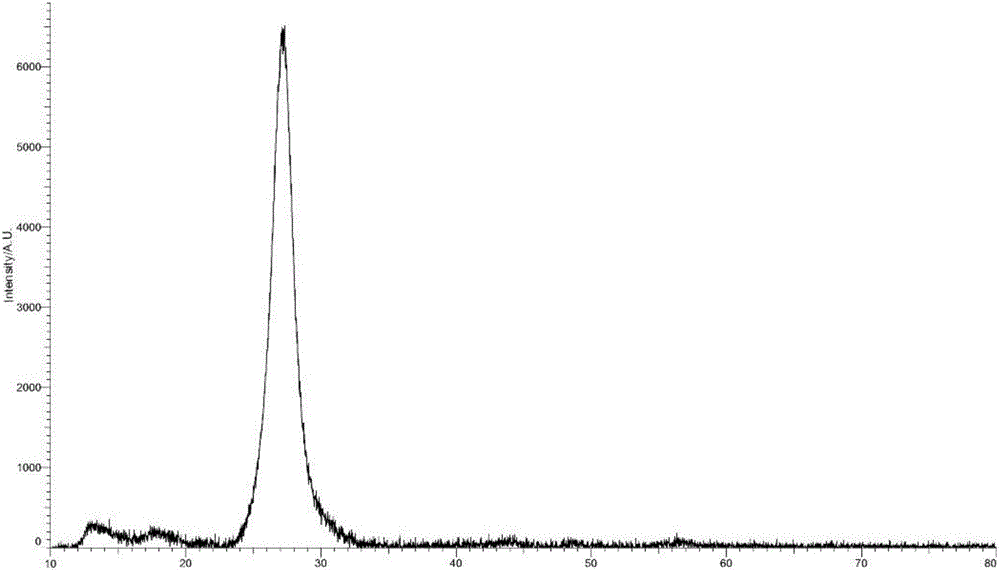

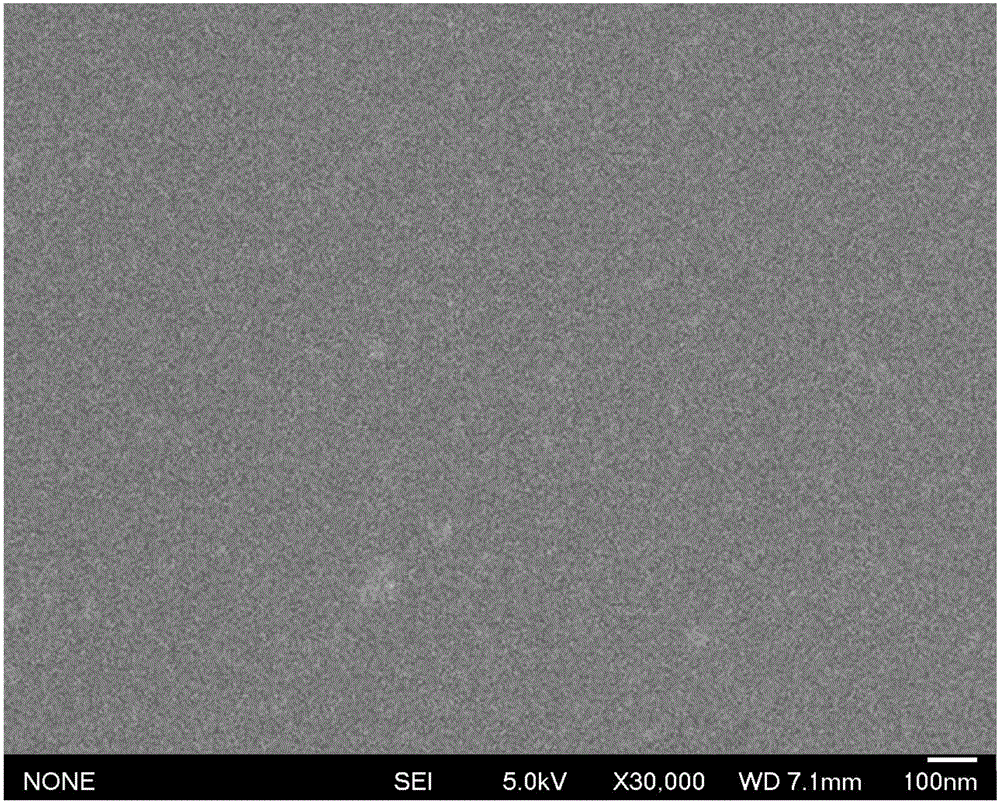

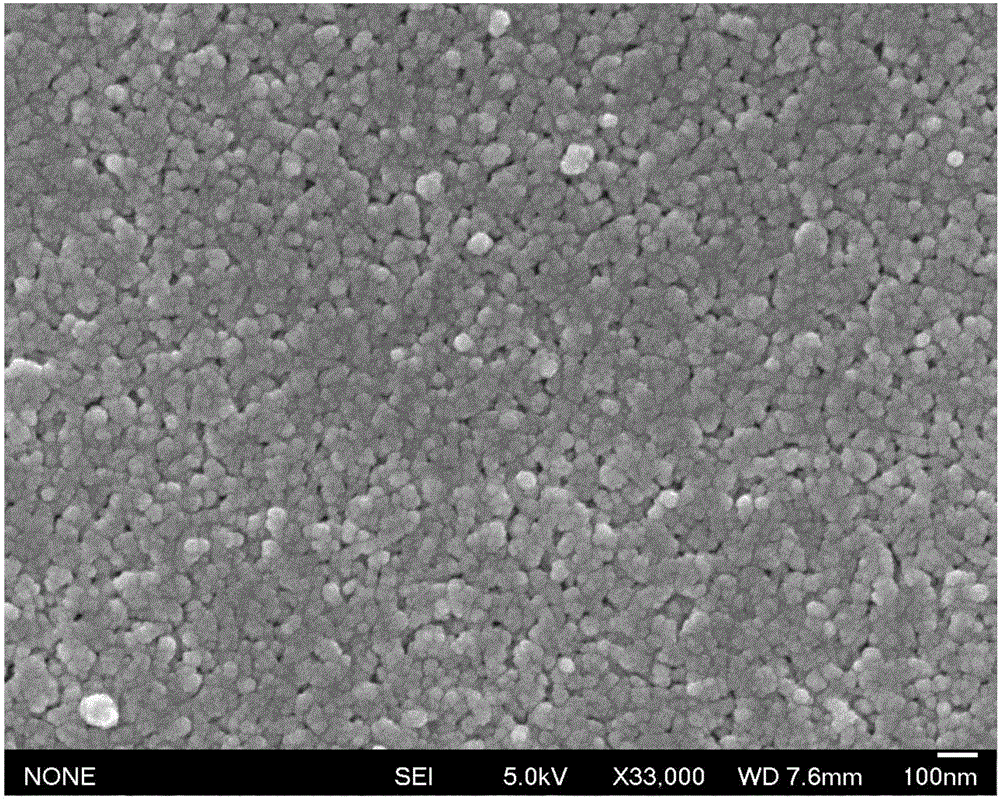

[0046] 1) Preparation of nano-carbon nitride powder: put a certain amount of urea in a reactor and calcinate at 480°C for 4h, drop to room temperature, and then put in 30% H 2 o 2 heated to 60°C for 16 hours, urea and H 2 o 2 The mass ratio of urea is 1:55; the reaction solution is filtered, the filter residue is calcined at 520°C for 4 hours, cooled to room temperature, put into water with 100 times the mass of urea and ultrasonically stripped for 15 hours, then centrifuged to take the supernatant, and dried to obtain nano-carbon nitride powder;

[0047] The ultrasonic power is 65W;

[0048] The centrifugal speed is 3200r / min, and the centrifugal time is 40min;

[0049] The particle size of the nano carbon nitride powder is 30nm;

[0050] 2) Preparation of modified nano-carbon nitride methanol solution: uniformly mix the nano-carbon nitride powde...

Embodiment 2

[0065] A method for directly utilizing sunlight to catalyze the degradation of phthalate pollutants, comprising the steps of:

[0066] 1) Preparation of nano-carbon nitride powder: put a certain amount of urea in a reactor and calcined at 400°C for 3 hours, then drop to room temperature, and then put in 30% H 2 o 2 Heated to 55°C for 8 hours, urea and H 2 o 2 The mass ratio of urea is 1:10; the reaction solution is filtered, the filter residue is calcined at 450°C for 3 hours, cooled to room temperature, put into water with 100 times the mass of urea and ultrasonically stripped for 6 hours, then centrifuged to take the supernatant, and dried to obtain nano-carbon nitride powder;

[0067] The ultrasonic power is 50W;

[0068] The centrifugal speed is 3000r / min, and the centrifugal time is 30min;

[0069] The particle size of the nano carbon nitride powder is 50nm;

[0070] 2) Preparation of modified nano-carbon nitride methanol solution: uniformly mix the nano-carbon nitr...

Embodiment 3

[0085] A method for directly utilizing sunlight to catalyze the degradation of phthalate pollutants, comprising the steps of:

[0086] 1) Preparation of nano-carbon nitride powder: put a certain amount of urea in a reactor and calcinate at 550°C for 5h, drop to room temperature, and then put in 30% H 2 o 2 Heated to 65°C for 24 hours, urea and H 2 o 2 The mass ratio of urea is 1:100; the reaction solution is filtered, the filter residue is calcined at 600°C for 5 hours, cooled to room temperature, put into water with 100 times the mass of urea and ultrasonically stripped for 24 hours, then centrifuged to take the supernatant, and dried to obtain nano-carbon nitride powder;

[0087] The ultrasonic power is 80W;

[0088] The centrifugal speed is 3500r / min, and the centrifugal time is 50min;

[0089] The particle size of the nano carbon nitride powder is 40nm;

[0090] 2) Preparation of modified nano-carbon nitride methanol solution: uniformly mix the nano-carbon nitride po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com