Method for innocent treatment and resource utilization of wastes

A harmless treatment and recycling technology, applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of high investment in incineration technology, difficult operation, high operating cost, etc., and achieve mature and reliable composition technology , to handle large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments are described below in conjunction with the accompanying drawings:

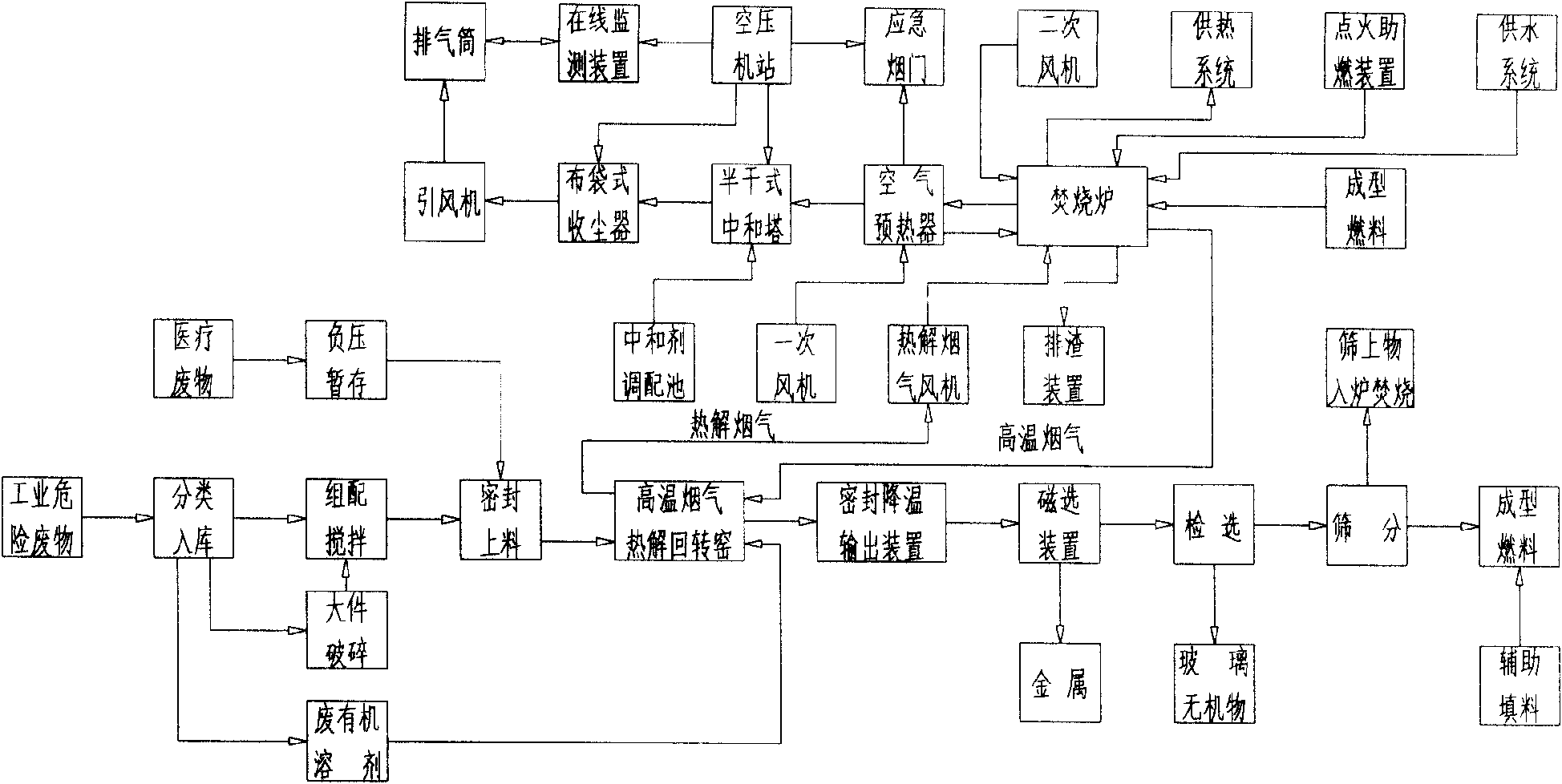

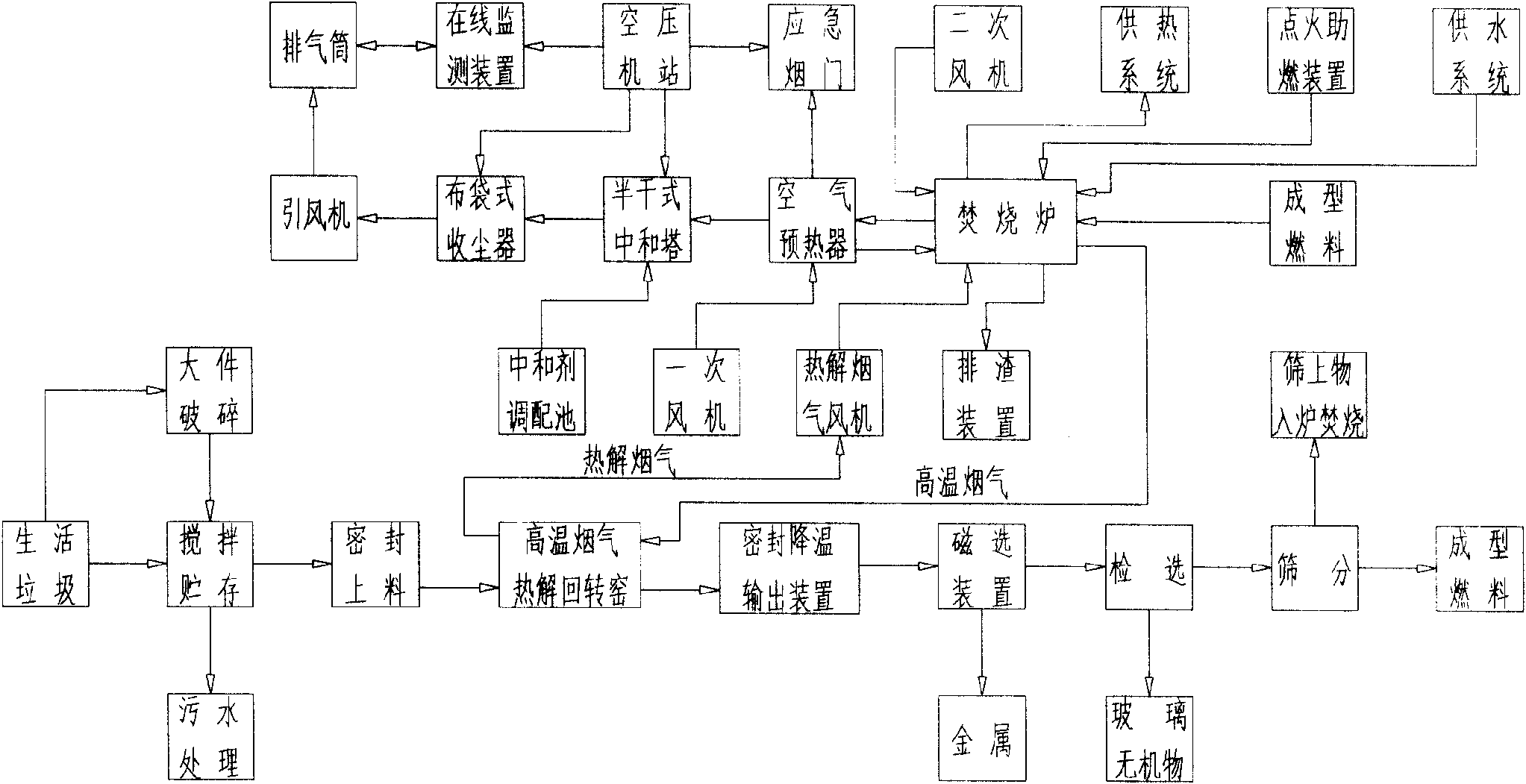

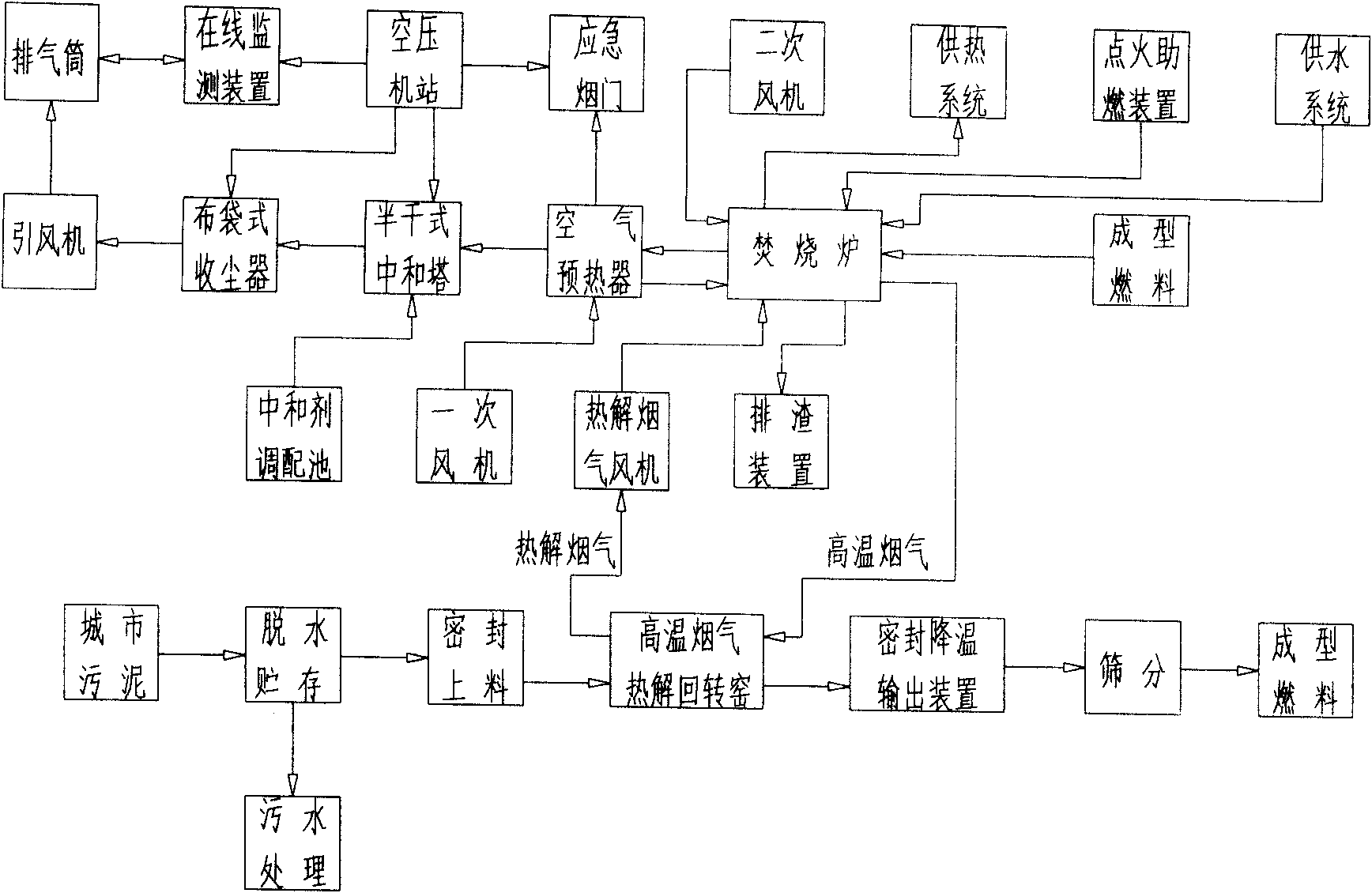

[0019] like Figure 1 to Figure 8 As shown, the specific technical content and method of a method for the harmless treatment and resource utilization of wastes of the present invention are as follows:

[0020] The present invention adopts pyrolysis and incineration treatment methods for related wastes. Its main content is: the wastes entering the storage hopper 2 are successively fed into the feed end of the rotary kiln 5 according to the requirements of the required pyrolysis treatment capacity by the hydraulic pushing device 1, and the wastes after entering the kiln are rotated and descended in the rotary kiln. Under the action of the inclination angle and other conditions, it moves evenly to the discharge end of the rotary kiln 5, and a part of the high-temperature flue gas generated by the incineration of the incinerator 14 is taken out at the high-temperature flue gas int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com