Treatment technique of garbage filter liquor

A landfill leachate and treatment process technology, applied in the field of landfill leachate treatment technology, can solve the problems of increased flow, investment and operation cost, reverse osmosis membrane is easily affected by temperature, evaporation technology cannot remove ammonia nitrogen, etc., and achieves treatment process and effect. The effect of stability, reduction of evaporation treatment cost and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

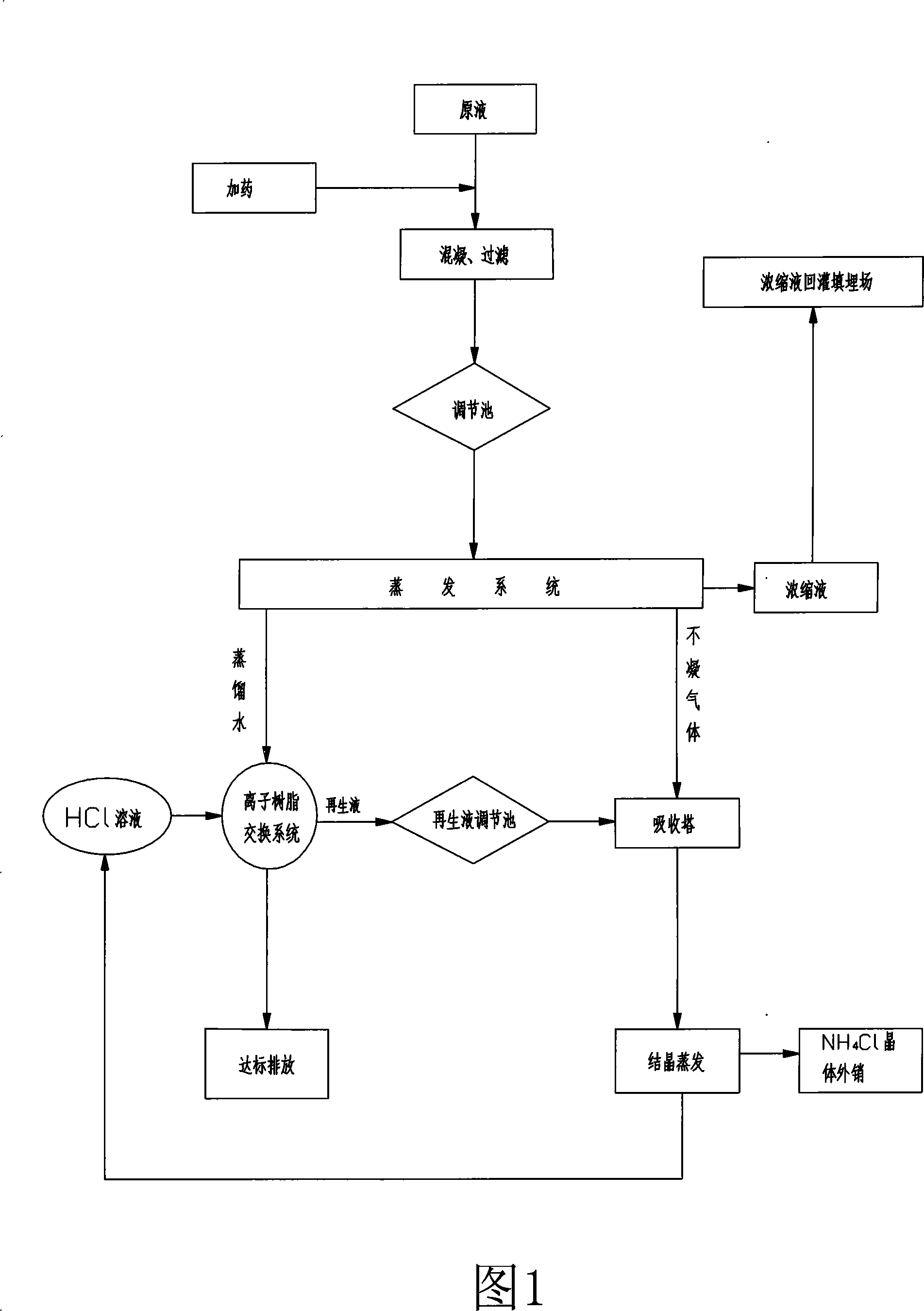

[0027] Embodiment 1 of the present invention, as shown in Fig. 1, Fig. 2, a kind of treatment process of landfill leachate, specifically comprises the following steps:

[0028] (1). First, add a coagulant to the landfill leachate. The coagulant can be selected from one of polyaluminum chloride, polyferric chloride or polyferric sulfate, and the fine particles in the leachate can be removed by coagulation and filtration. Fibers, to prevent the tiny fibers from wrapping and changing the heating tube bundle during the evaporation process in the later stage, so as to ensure the efficiency of evaporation and the normal operation of the equipment;

[0029] (2). After filtration to remove fine fibers, the leachate enters the adjustment tank, and the function of the adjustment tank is to control the amount of leachate entering the evaporation system;

[0030] (3). The leachate from the regulating tank enters the evaporation system. After evaporation, water and ammonia are boiled out o...

Embodiment 2

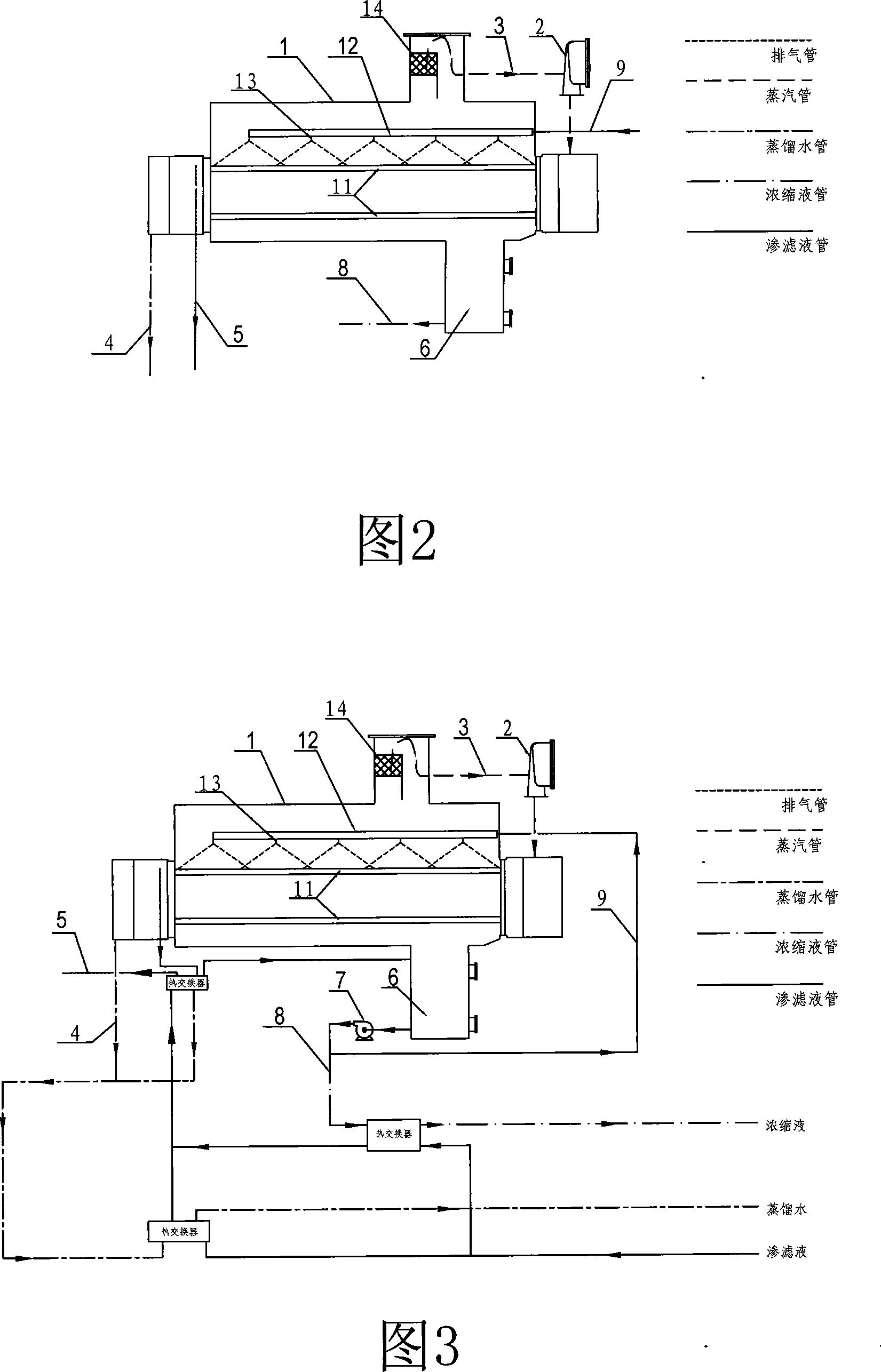

[0034] Embodiment 2 of the present invention is as shown in Figure 1 and Figure 3. The difference from the previous embodiment is that before the leachate enters the evaporator 1 of the evaporation system, it is first mixed with the distilled water, non-condensable gas and concentrated liquid discharged from the evaporation system. Heat exchange is carried out through a heat exchanger to preheat the leachate. The distilled water pipe 4, the exhaust pipe 5 and the concentrated liquid pipe 8 are respectively connected to the heat exchanger, and the waste heat is transferred to the heat exchanger, and the leachate pipe 9 is also connected to the heat exchanger, so as to make full use of the waste heat of the above three discharges, Therefore, the temperature of the landfill leachate that needs to be treated is close to the boiling point before entering the evaporator 1, which improves the utilization efficiency of electric energy and achieves the purpose of further saving energy. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com