Biomass abnormal circulating fluidized bed gasifier

A circulating fluidized bed and biomass technology, applied in the direction of granular/powdered fuel gasification, educts, reagents, etc., can solve the problems of high tar, high operating temperature of the entrained bed, and difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

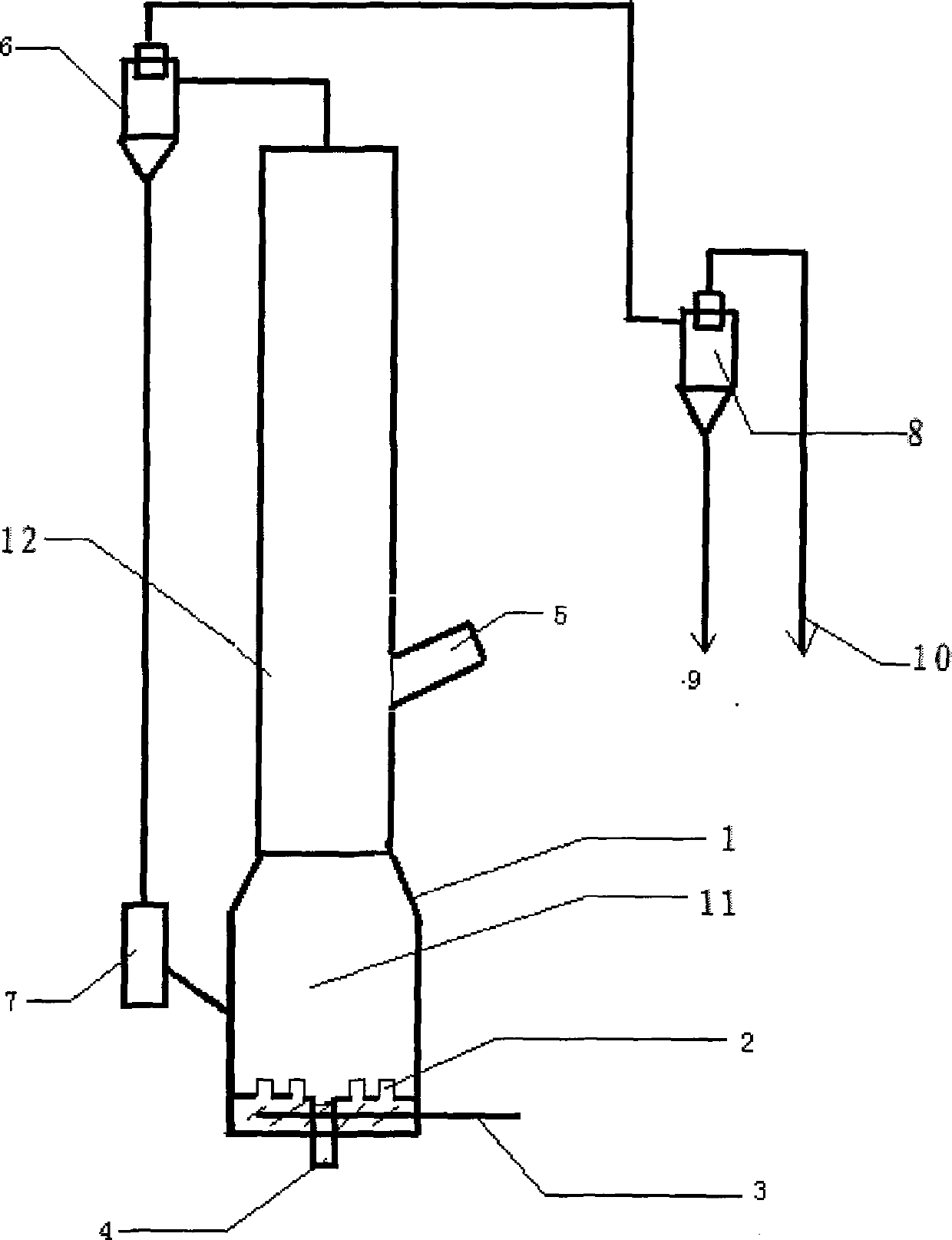

[0014] The biomass special-shaped circulating fluidized bed gasifier consists of a special-shaped circulating fluidized bed (1), a gas distributor (2), an air inlet pipe (3), an ash discharge pipe (4), a biomass feed port (5), a Composed of a first-stage gas-solid separator (6), a feeder (7), a second-stage gas-solid separator (8), a silicon potassium fertilizer outlet (9), and a gas outlet (10), it is characterized in that the combined fluidized bed (1 ) is provided with a gas distributor (2), an air inlet pipe (3) and an ash discharge pipe (4) at the bottom, an air inlet pipe (3) is arranged under the gas distributor (2), and the ash discharge pipe (4) is arranged (2) center or triangular distribution; a Y-shaped connected swirling airflow bed (11) is provided at a position 1000-2000mm away from the bottom, and pulverized coal is provided at a position 500-3000mm above the swirling airflow bed (11). The feed inlet (5) is provided with a primary gas-solid separator (6) and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com