Method for preparing marsh gas and producing sintered bricks by using municipal sludge

A municipal sludge and sludge brick-making technology, which is applied in biological sludge treatment, ceramic material production, dehydration/drying/concentrated sludge treatment, etc. The problem of high cost is to achieve the effect of fine sludge particles, large processing scale and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

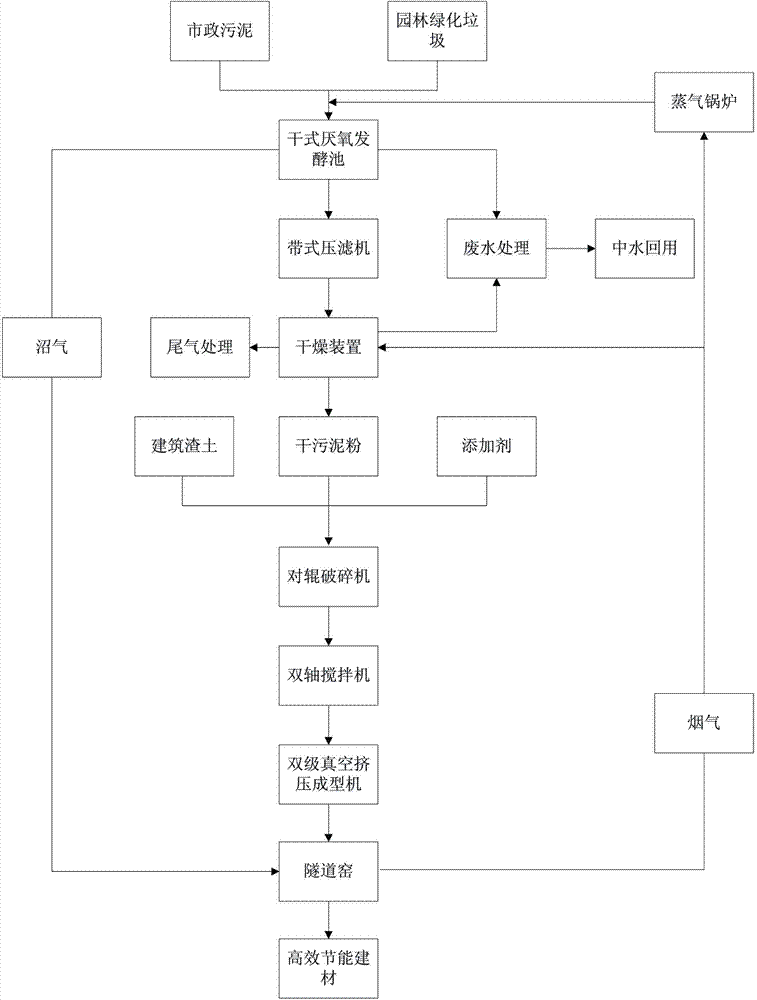

[0032] Now with reference to the accompanying drawings, the embodiments of the present invention will be described in detail.

[0033] Such as figure 1 Shown, municipal sludge of the present invention prepares biogas and produces sintered brick method and comprises the following steps:

[0034] Step 1: Municipal sludge, with a moisture content of about 80%, is poured into the raw material receiving tank. There is a raised floor in the raw material receiving tank. During the operation, the sludge is initially mixed and stirred, and the sludge is quantitatively taken out of the receiving tank and sent to subsequent equipment.

[0035] Step 2: After the sludge is lifted, it is directly sent to the dry fermentation tank feeding device. The steam is sent to the feed device of the dry fermenter through the pipeline, mixed with the sludge, heated up, and sent into the dry fermenter through the pipeline.

[0036] Step 3: After the sludge is sent into the dry fermentation tank, biod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com