Modified plastic, and preparation method and application thereof

A plastic modification technology, which is applied in the field of polymer material recycling and modification, can solve the problems of unsatisfactory performance of composite flooring, and achieve the effect of simple and practical method, saving material resources and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

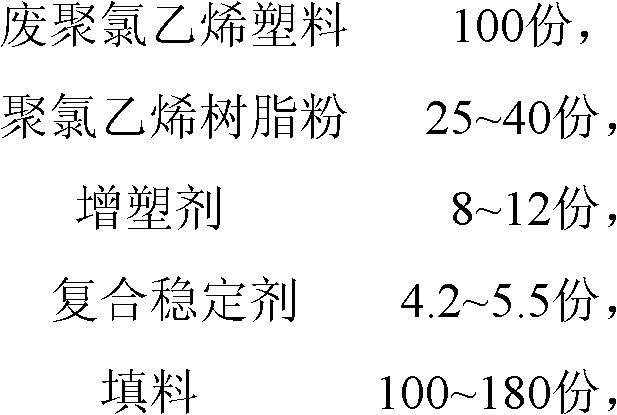

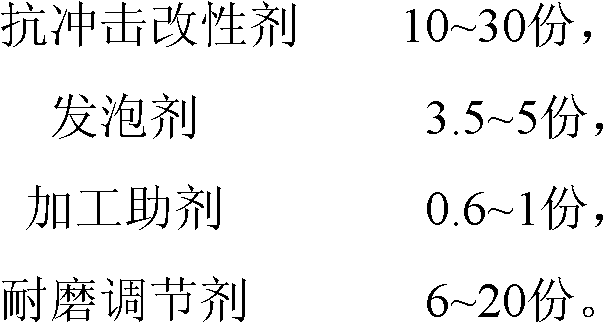

Method used

Image

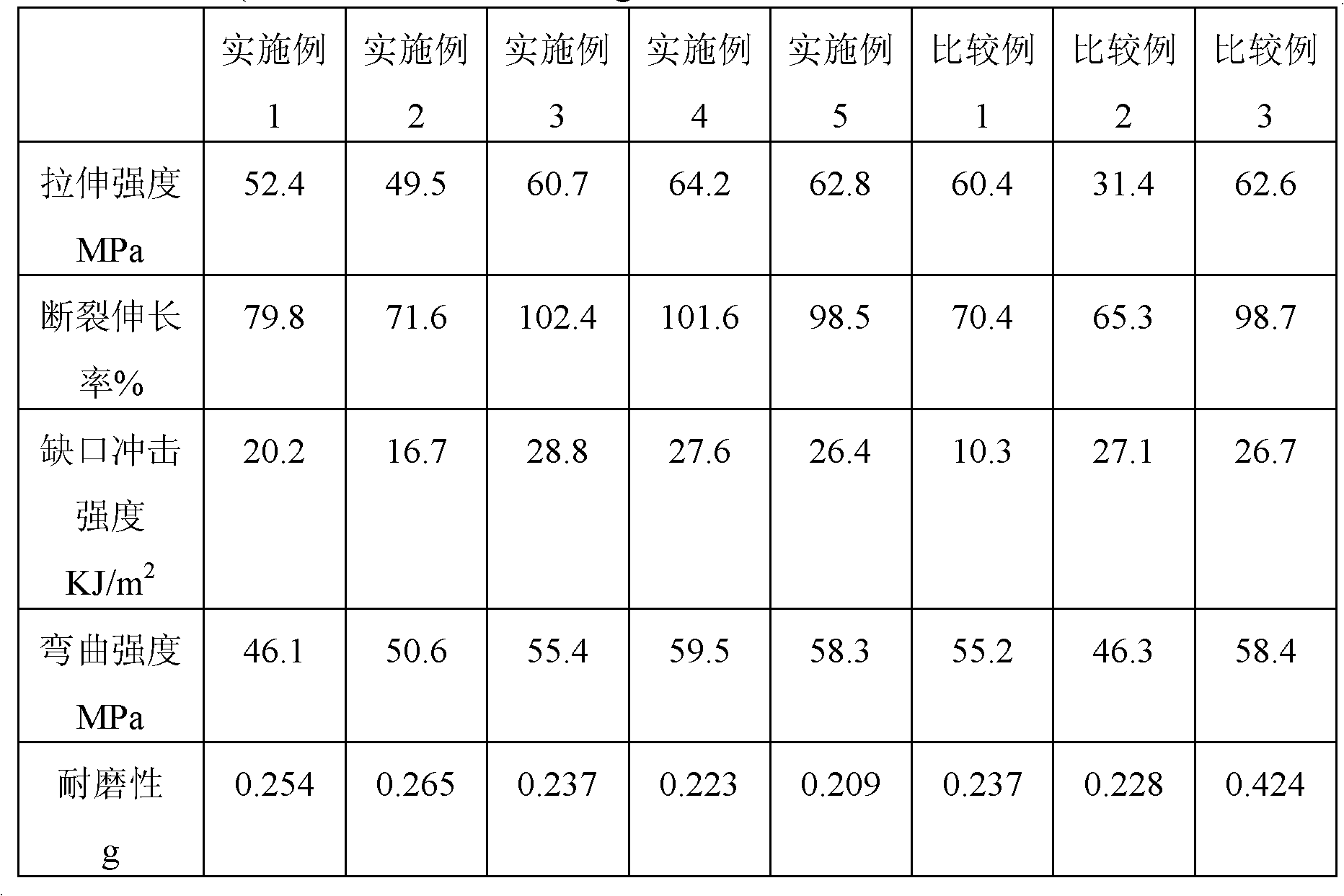

Examples

Embodiment 1

[0031] (1) Clean and crush the recovered waste polyvinyl chloride plastics, grind them into waste polyvinyl chloride powder, dry them in an oven for 13 hours at a temperature of 78°C, and set aside;

[0032] (2) Get 100 parts of the above waste polyvinyl chloride powder and 28 parts of polyvinyl chloride resin powder, add 10 parts of dinonyl phthalate, composite stabilizer (3.5 parts of dibasic lead phosphite and barium stearate 1.2 parts), 120 parts of calcium carbonate, 15 parts of chlorinated polyethylene, 3.8 parts of azodicarbonamide, 0.8 parts of zinc stearate, wear-resistant modifier (6 parts of tire powder and 3 parts of carbon black), heated at high speed Mixing, the heating temperature is 100°C, the rotation speed is 88r / min, and the mixing time is 12min;

[0033] (3) Mix the above mixed material with two rolls, the temperature of the front roll is 145°C, the temperature of the rear roll is 160°C, the roll distance is 0.6mm, the roll pressing time is 15min, the sheet...

Embodiment 2

[0037] (1) Clean and crush the recovered waste polyvinyl chloride plastics, grind them into waste polyvinyl chloride powder, dry them in an oven for 14 hours at a temperature of 72°C, and set aside;

[0038] (2) Get 100 parts of above-mentioned waste polyvinyl chloride powder and 30 parts of polyvinyl chloride resin powder, add 10 parts of dibutyl phthalate, composite stabilizer (3.2 parts of tribasic lead sulfate and 1.0 parts of cadmium stearate parts), 100 parts of kaolin, 10 parts of methyl methacrylate copolymer, 4.2 parts of azobisisobutyronitrile, 1.0 parts of stearic acid, wear-resistant modifier (4 parts of rubber powder and 2 parts of carbon black), after heating High-speed mixing, the heating temperature is 110°C, the rotation speed is 95r / min, and the mixing time is 12min;

[0039] (3) Mix the above mixed material with two rolls, the temperature of the front roll is 150°C, the temperature of the rear roll is 165°C, the roll distance is 0.5mm, the roll pressing time...

Embodiment 3

[0043] (1) Clean and crush the recovered waste polyvinyl chloride plastics, grind them into waste polyvinyl chloride powder, dry them in an oven for 12 hours at 80°C, and set aside;

[0044] (2) Get 100 parts of above-mentioned waste polyvinyl chloride powder and 25 parts of polyvinyl chloride resin powder, add 8 parts of dioctyl terephthalate, composite stabilizer (3.8 parts of dibasic lead phosphite and barium stearate 1.7 parts), filler (calcium carbonate 80 parts and talcum powder 70 parts), chlorinated polyethylene 20 parts and EPDM rubber 10 parts, azodicarbonamide 3.5 parts, polyethylene wax 0.6 parts, wear-resistant modifier (8 parts of tire powder and 5 parts of iron powder), heated and mixed at high speed, the heating temperature is 120°C, the rotation speed is 100r / min, and the mixing time is 10min;

[0045] (3) Mix the above-mentioned mixed material with two rolls, the temperature of the front roll is 150°C, the temperature of the rear roll is 170°C, the roll dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com