Multistage gradient adsorption channel adsorption technology

An adsorption tank and gradient technology, which is used in adsorption water/sewage treatment, solid adsorbent liquid separation, energy and wastewater treatment, etc. problems, to achieve the effect of convenient maintenance and update, good water output and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Adsorption material pretreatment

[0033] The adsorbent is: peat. Dry the adsorbent in the sun, then crush the particles to 50 meshes, and then moisten it with water when using, and wait for it to be used after completely absorbing water.

[0034] 2. Pre-treatment of industrial wastewater

[0035] Preparation of simulated wastewater: Dissolve CaCl2 solid in 1000mL of distilled water, add distilled water to constant volume, and make Cd concentration of 56.0mg L -1 The heavy metal solution, at this time the pH is 6. The preparation of the simulated wastewater used in the comparative example is the same.

[0036] 3. Column adsorption

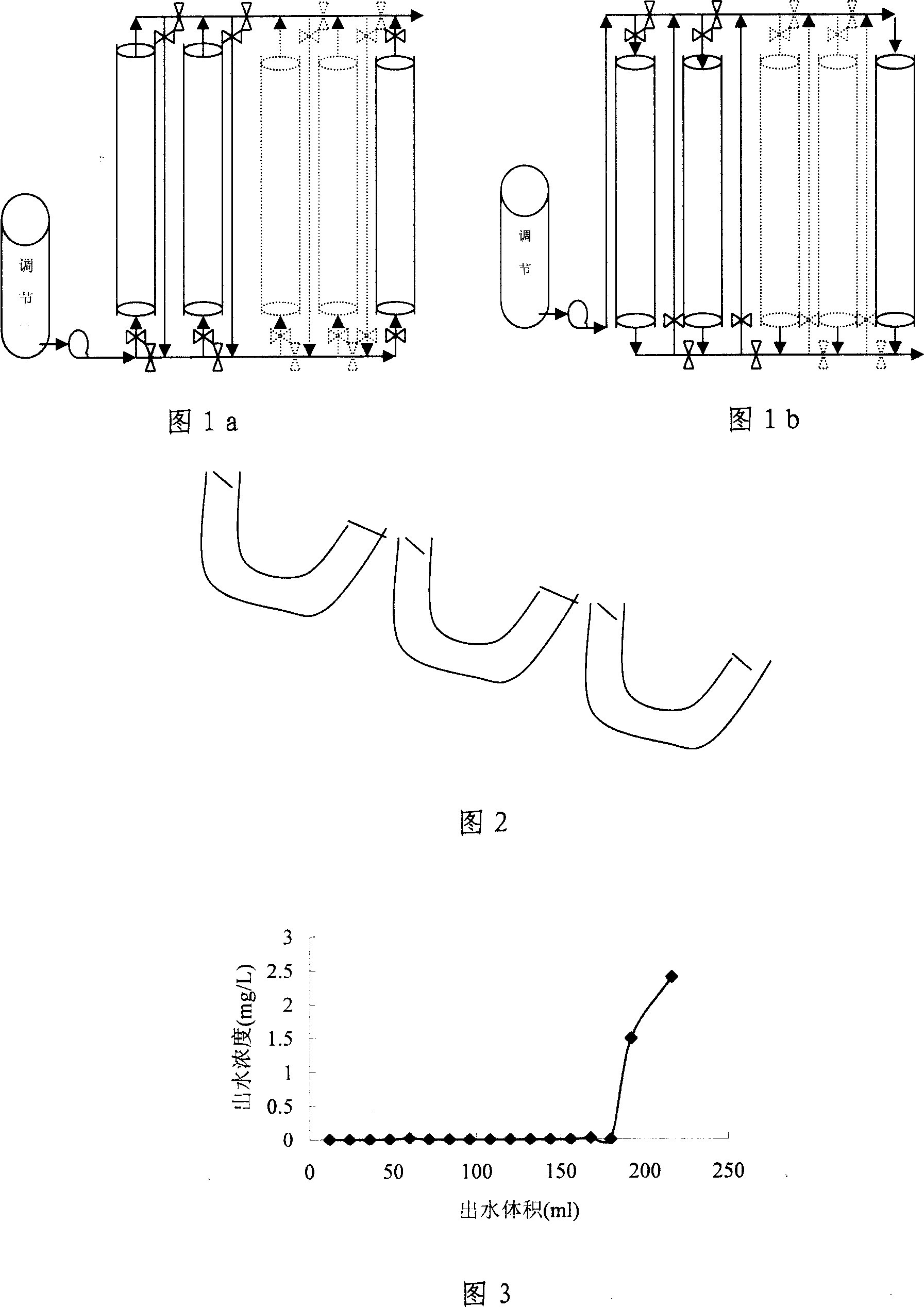

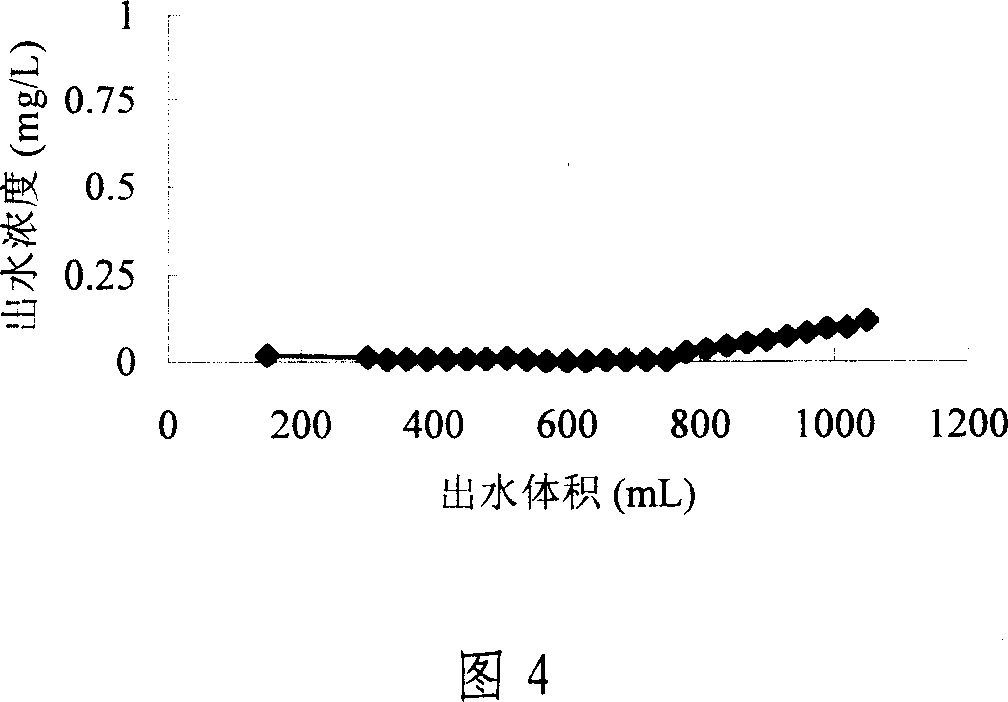

[0037] The adsorption column is: a self-flowing multi-stage gradient adsorption column in series (see Figure 2). This embodiment adopts a series asymmetric U-shaped adsorption column. The adsorption column is 3 cm high and arranged from top to bottom. The two adjacent column outlets and inlets Connected, and the height difference betwe...

Embodiment 2

[0042] Embodiment 2: process the industrial waste water containing heavy metal

[0043] 1. Adsorption material pretreatment

[0044] The adsorbent is: the natural adsorbent after embedding modification is: chitin. Dry the adsorbent in the sun, then crush the particles to 100 meshes, then moisten it with water when using it, and wait for it to be used after completely absorbing water.

[0045] 2. Pre-treatment of industrial wastewater

[0046] Industrial wastewater containing high concentration of heavy metals--acid wastewater, in which the highest content of heavy metals is Cd and Zn, most of which are free Cd and Zn. Use 10% and 0.5% NaOH, a total of 100mL to adjust to PH = 9.0. Then the adjusted sewage is used to remove the suspended matter with larger particles in the wastewater by sedimentation.

[0047] pH of industrial waste water

water type

heavy metal

shape

Cd (mg / L)

Pb(mg / L)

Cu(mg / L)

Zn(mg / L)

Acid wa...

Embodiment 3

[0056] 1. Adsorption material pretreatment:

[0057] The adsorbent is: the natural adsorbent after sulfonation modification is: diatomaceous earth. Dry the adsorbent in the sun, then crush it into 200-mesh granules, then soak it in water when it is used, and wait for it to be used after completely absorbing water.

[0058] 2. Pretreatment of sewage to be treated

[0059] The preparation of the simulated wastewater was the same as in Example 1, and the pH was adjusted to 4.0 with 5% and 1.0% HCl.

[0060] 3. Column adsorption

[0061] The adsorption column is: a network type self-flowing multi-stage gradient adsorption column. The parallel adsorption columns arranged in parallel are connected by pipelines to form a one-to-three connection mode, that is, a network. The water level of the water inlet of a single adsorption unit is higher than that of the outlet. The water level difference of the water outlet is 1cm. The water sample treated by the adsorption column of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com