Device and method for efficient roll-to-roll preparation of cadmium sulfide thin film

A cadmium sulfide, roll-to-roll technology, applied in gaseous chemical plating, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as incoherent steps, discontinuous production of cadmium sulfide buffer layer film, and low efficiency. Achieve the effects of improving production efficiency, simple structure, and uniform film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

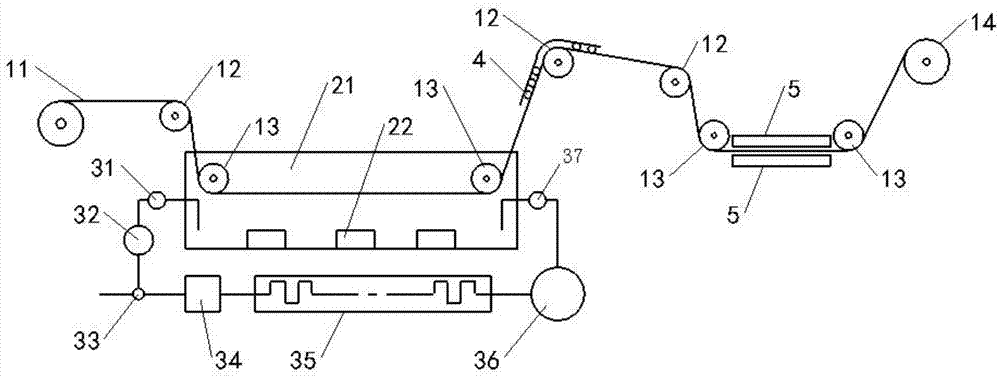

[0024] figure 1 As shown, a device for efficiently preparing cadmium sulfide film roll-to-roll includes: a conveying mechanism for flatly conveying a flexible substrate, a deposition box for deposition reaction, a solution heating circulation mechanism connected to the deposition box, and a scrubbing lining. The roller washing mechanism at the bottom and the drying device for drying the substrate; the deposition box, the roller washing mechanism and the drying device are arranged in sequence along the conveying direction of the substrate.

[0025] The conveying mechanism includes: a reel located at the beginning and end of the substrate conveying route to wind the substrate into a roll, a plurality of guide rollers located in the substrate conveying route to guide the conveying direction of the substrate, and position the substrate Multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com