Radiation system for calculation processing arrangements and equipment adopting the heat radiation system

A technology of cooling system and processing equipment, applied in computing, electrical digital data processing, digital data processing components and other directions, can solve the problems of reducing the comfort of the working environment, lack of installation flexibility, affecting work efficiency, etc., to achieve installation and replacement Convenience, easy centralized management, and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

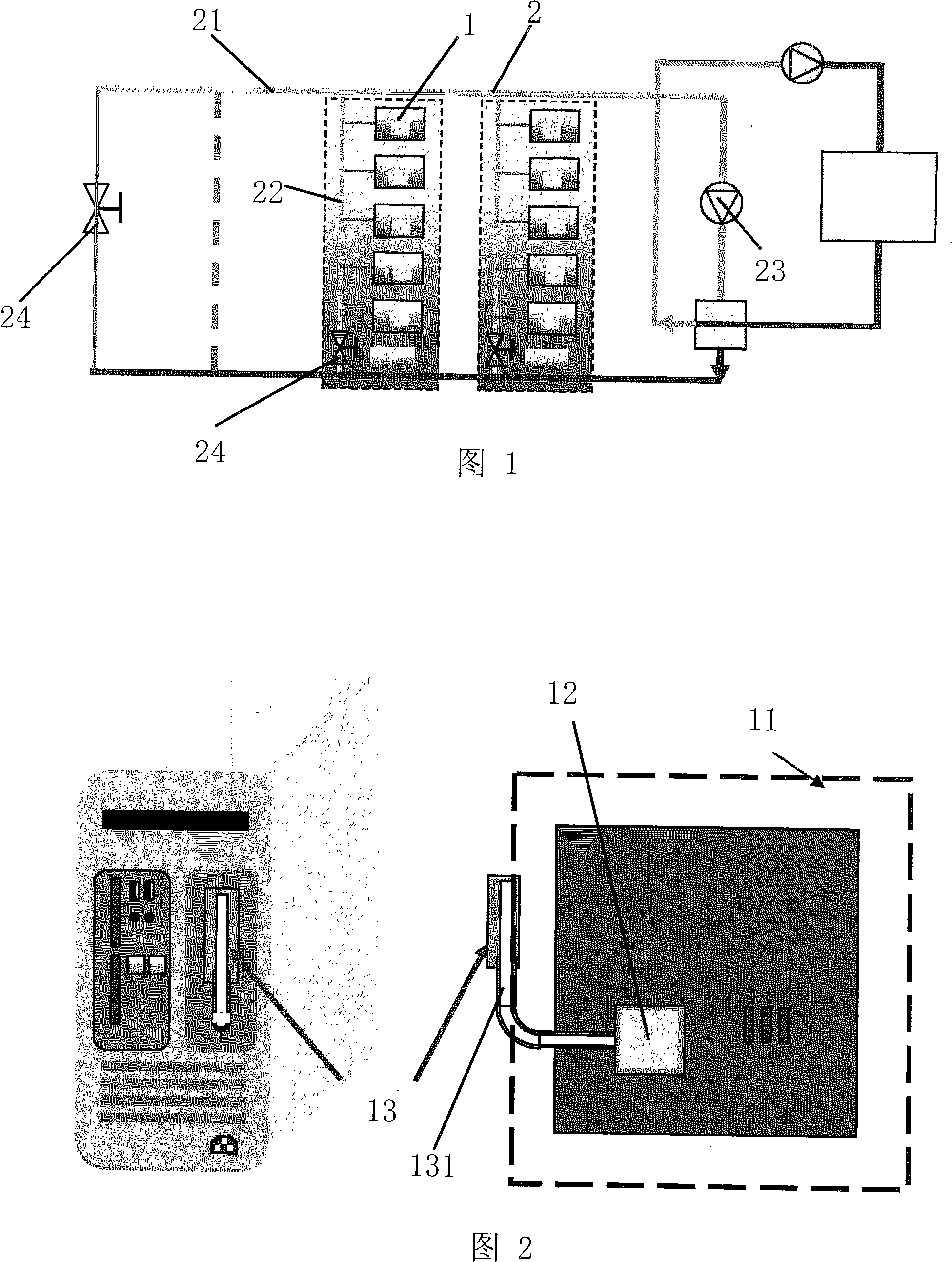

[0042] As shown in Figure 2, in this embodiment, the heat conduction connector of the present invention is used in a computer 1, which includes a chassis 11, a heat source 12 inside the computer 1, and a heat conduction connector 13 arranged on the chassis 11 and connected to the heat source 12 . The heat source 12 includes a CPU, a DSP, or an integrated chip of a CPU and a DSP, but is not limited to the above-mentioned heat source, and may also include other heating elements inside the computer 1 . The heat transfer modes between the computer 1 and the cooling circuit 2 include plug-in solid / solid contact heat transfer, fluid / solid interface heat exchange and heat transfer, and the like.

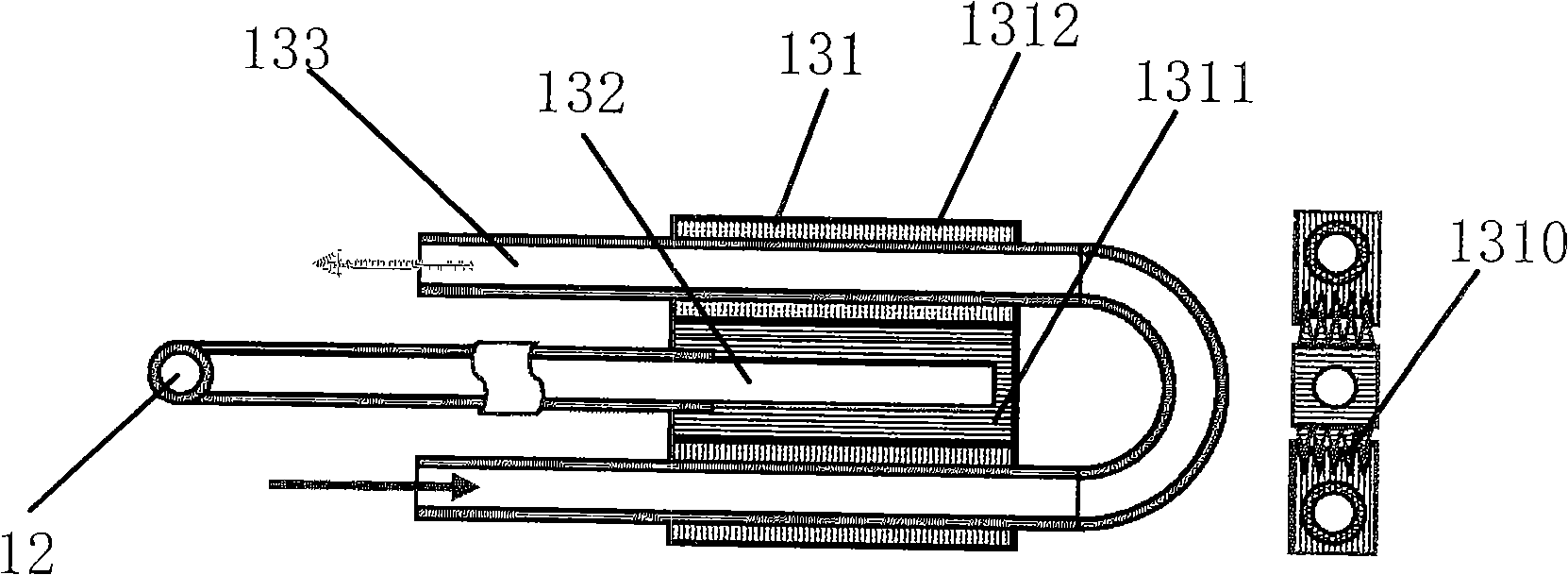

[0043] Such as image 3 As shown, the heat conduction connector 13 of the first embodiment of the heat conduction connector of the present invention includes a connector housing 131 installed on the computer 1, a heat pipe 132 arranged in the connector housing 131 and connected to the heat ...

Embodiment 2

[0046] Such as Figure 4 As shown, other parts of this embodiment are the same as Embodiment 1, the difference is:

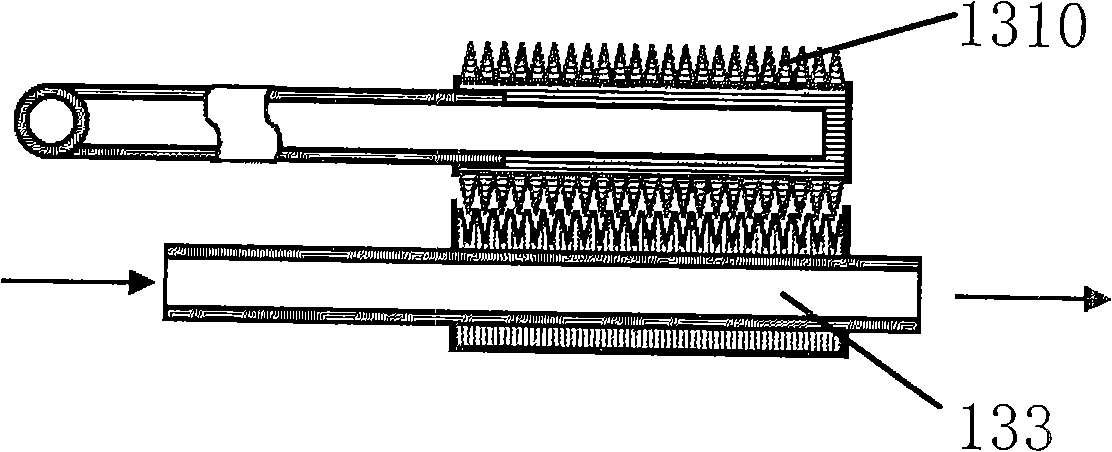

[0047] The first heat conductor 1311 and the second heat conductor 1312 also have sawtooth heat conduction ribs 1310 on the outer surfaces, and the sawtooth heat conduction ribs 1310 in this embodiment are perpendicular to the extension direction of the heat pipe 132 (that is, parallel to the extension direction of the conduit 133 Vertical), can also achieve the effect of increasing the heat transfer area and enhancing the heat dissipation effect.

Embodiment 3

[0049] Such as Figure 5 The thermally conductive connector 13 shown is a single closed solid / fluid thermally conductive type. The heat-conducting connector 13 includes a connector housing 131 mounted on the chassis 11 of the computer 1 , and a heat pipe 132 disposed in the connector housing 131 and connected to the heat source 12 . The connector housing 131 is a single-layer structure with a fluid inlet 1313 and a fluid outlet 1314 on both sides. The cooling medium enters the connector housing 131 from the fluid inlet 1313, exchanges heat with the heat pipe 132, and then absorbs the heat for cooling. The media exits the connector housing 131 through fluid outlet 1314 . That is, heat exchange is performed between the solid heat pipe 132 and the fluid cooling medium to cool the heat pipe 132 . Spiral fins or external threads 1321 are arranged inside the connector housing 131 and around the heat pipe 132, and the fins or external threads 1321 can be welded on the end of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com