Washing treatment method for heavy metal contaminated soil

A technology of polluted soil and treatment method, applied in the field of leaching treatment of heavy metal polluted soil, can solve the problems of low cost, large workload of planting sedum with ore and harvesting plants, long cycle and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

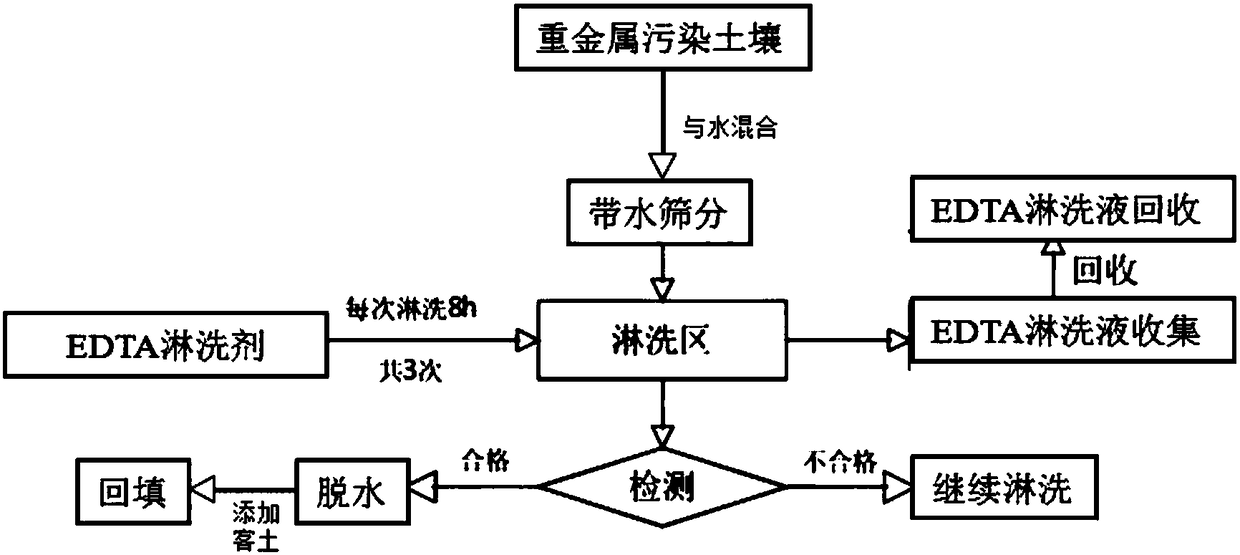

[0036] The soil polluted by heavy metals has been rinsed in a certain place, and the process is as follows figure 1 As shown, it specifically includes the following steps:

[0037] (1) After mixing heavy metal contaminated soil with water, sieve with water;

[0038] (2) Send the sieved soil treated in step (1) to the leaching tank, inject the eluent and stir for 7 to 9 hours, settle for 1 to 3 hours, collect the eluent and enter the recovery system for recycling;

[0039] (3) Step (2) is repeated to detect the soil after rinsing until the test result is qualified;

[0040] (4) dehydrating the qualified soil after step (3) processing;

[0041] (5) Add guest soil to the dehydrated soil treated in step (4) and then backfill.

[0042]The standard of sieving described in step (1) is soil particle diameter<30mm, and the eluent described in step (2) is EDTA disodium solution, and concentration is 0.05~0.2mol / L, and the described sieving soil of step (2) The volume ratio with the ...

Embodiment 2

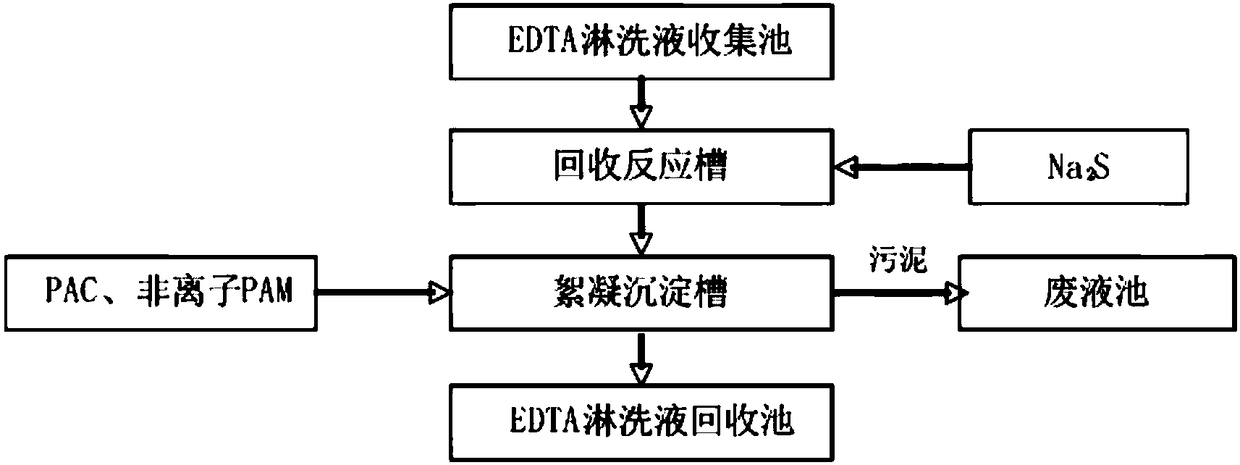

[0053] The EDTA eluent needs to enter the eluent recovery device for processing after multiple leaching, otherwise the leaching effect is not ideal. This embodiment provides a method for recycling the eluent, and the process is as follows figure 2 shown.

[0054] First, the EDTA eluent after multiple leaching is sent from the collection pool to the recovery reaction tank, and Na 2 After the precipitation of S, add the inorganic salt coagulant polyaluminum chloride (PAC). The role of this aspect is to precipitate and filter out the particulate matter that can be oxidized by the oxidant to increase the COD value, thereby reducing the COD, the precipitation of particulate matter, and also reducing the suspended solids. Then add non-ionic polyacrylamide (PAM). PAM is a commonly used non-ionic polymer flocculant in China. The molecular weight is 1.5 million to 9 million. The commercial concentration is generally 8%, which can form larger flocs between particles. , resulting in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com